Medical sterilization packaging bag

A packaging bag and medical technology, which is applied in the field of packaging bags, can solve the problems of high temperature resistance, high price, and a lot of cotton dust, and achieve good strength, reduce production costs, and simplify the connection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

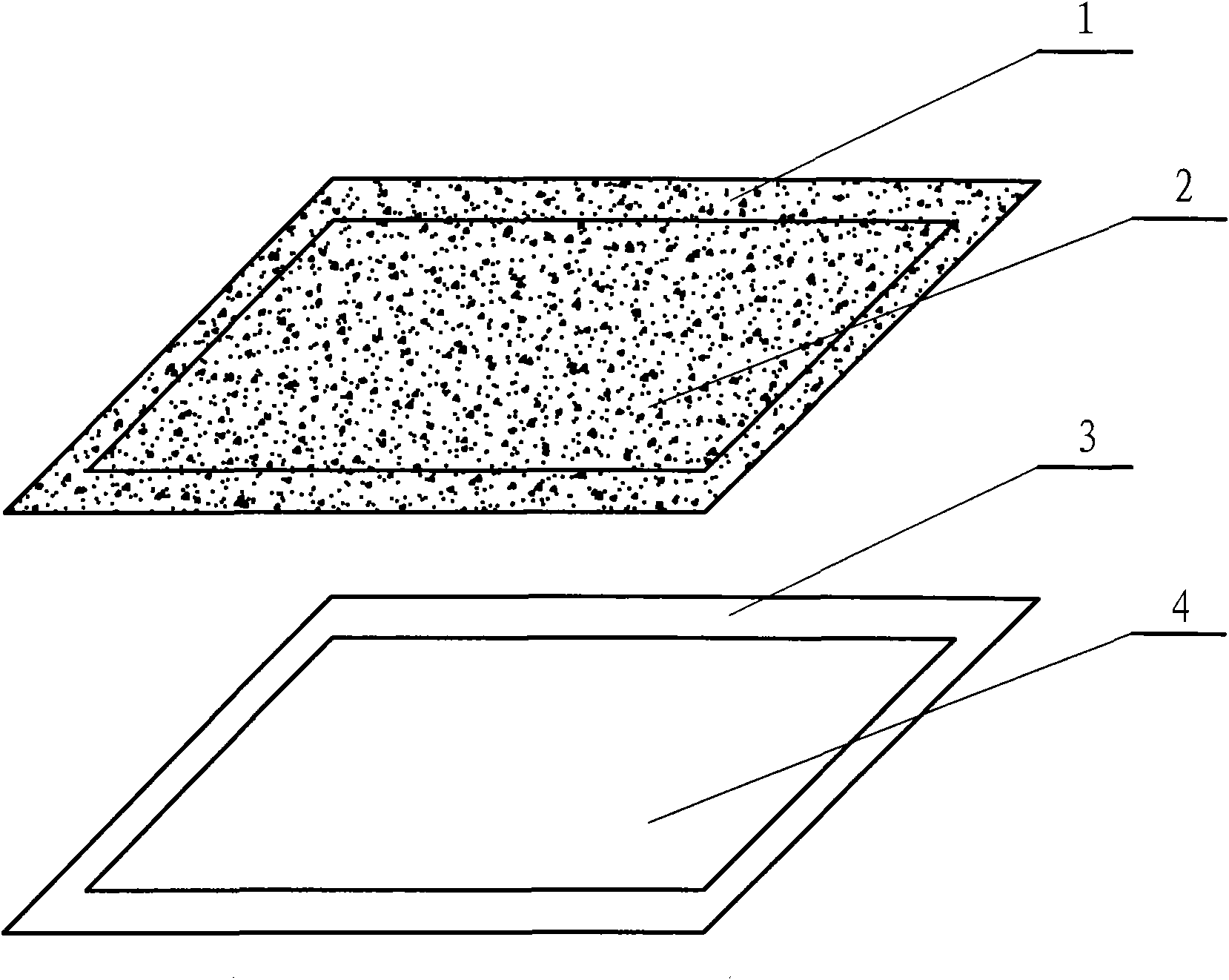

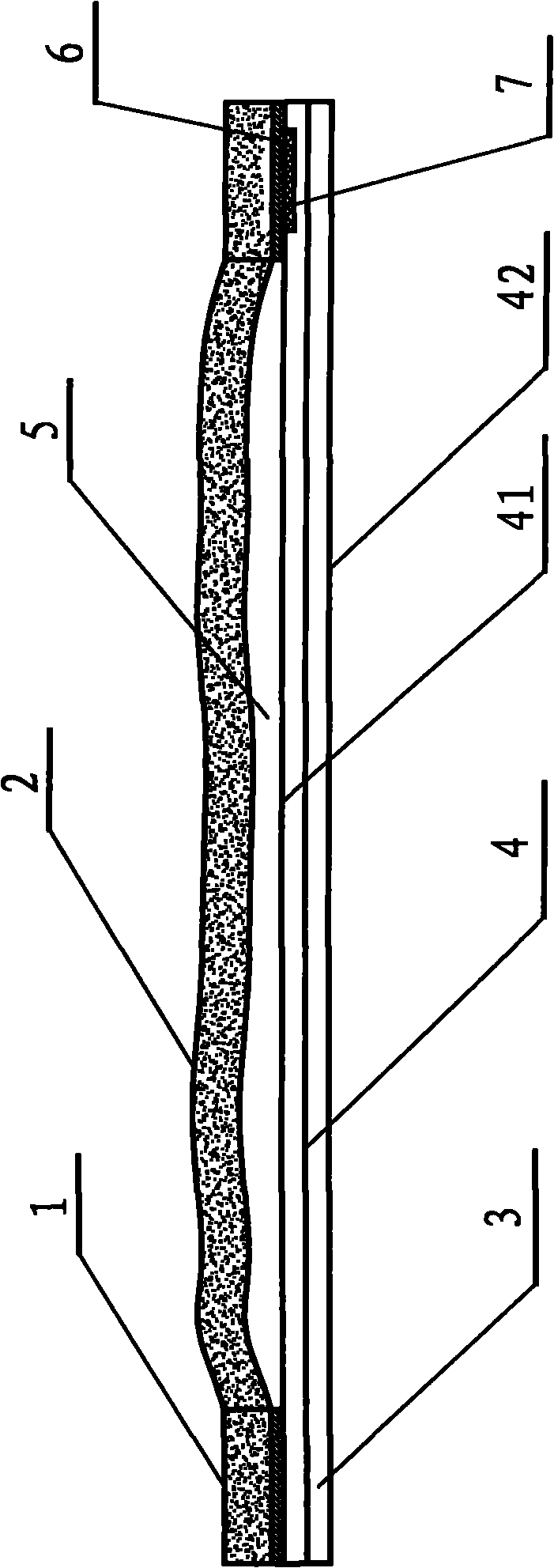

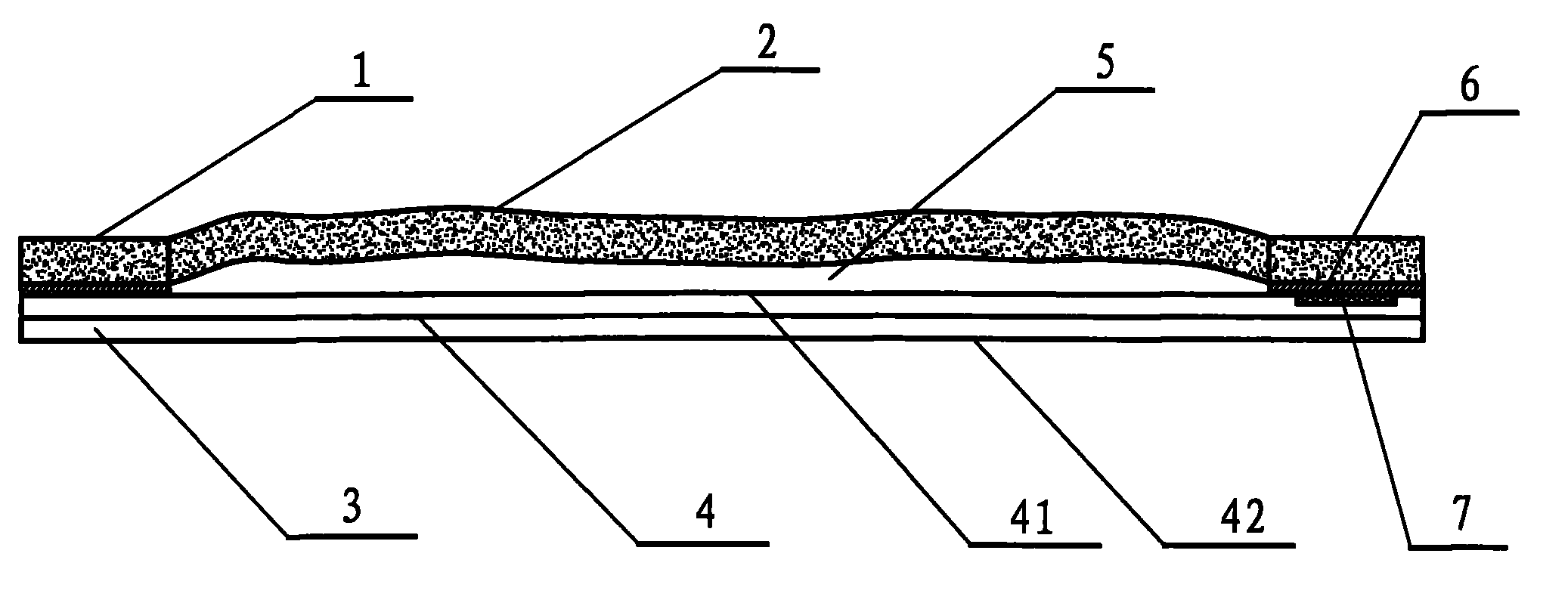

[0025] The medical sterilization packaging bag of the present invention is composed of a closed cavity formed by connecting corresponding parts of medical sheet-shaped flexible materials, and the contents are located in the closed cavity, and its structure is as follows: figure 1 As shown, there are at least two sheets of medical sheet-like flexible material, one of which is a transparent high-temperature-resistant medical composite plastic film 4 , and the other is a medical non-woven fabric 2 . The opposite sides of the transparent high-temperature-resistant medical composite plastic film 4 and the medical non-woven fabric 2 are connected by heat-welding or high-temperature-resistant adhesive in a manner of facing each other. The heat-sealing connection can be performed by a heat-sealing machine or by ultrasonic Welding machine is performed. When using high-temperature-resistant adhesives for bonding and connection, appropriate medical high-temperature-resistant adhesives sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com