One-piece ball-throwing and segmenting wall scraper

An integrated, wall scraper technology, used in cleaning appliances, wellbore/well components, earth-moving drilling, etc., can solve the problems of simultaneous entry of tools, complicated processes, and always open, so as to reduce operation time and ensure cleaning. effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

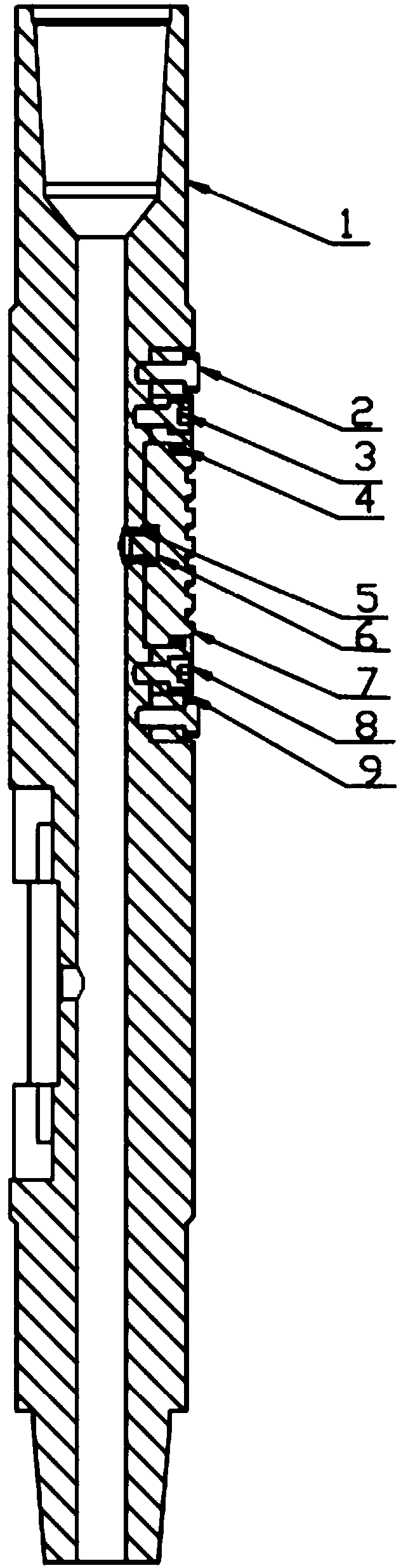

[0032] Depend on Figure 2 to Figure 15 As shown, the integrated ball-pitching segmental wall scraper includes a body 1 in the shape of a cylindrical tube. When working, the upper part of the body is connected to the drill pipe and lowered into the well. It is characterized in that: the integrated ball-pitching segmental wall scraper includes Outer hexagon bolt 2, inner hexagon bolt 3, slider lower spring 4, inner sleeve 5, pressure plug 6, scraper body 7, slider 8, pressure block 9, scraper lower spring 18 and pressure piece 16;

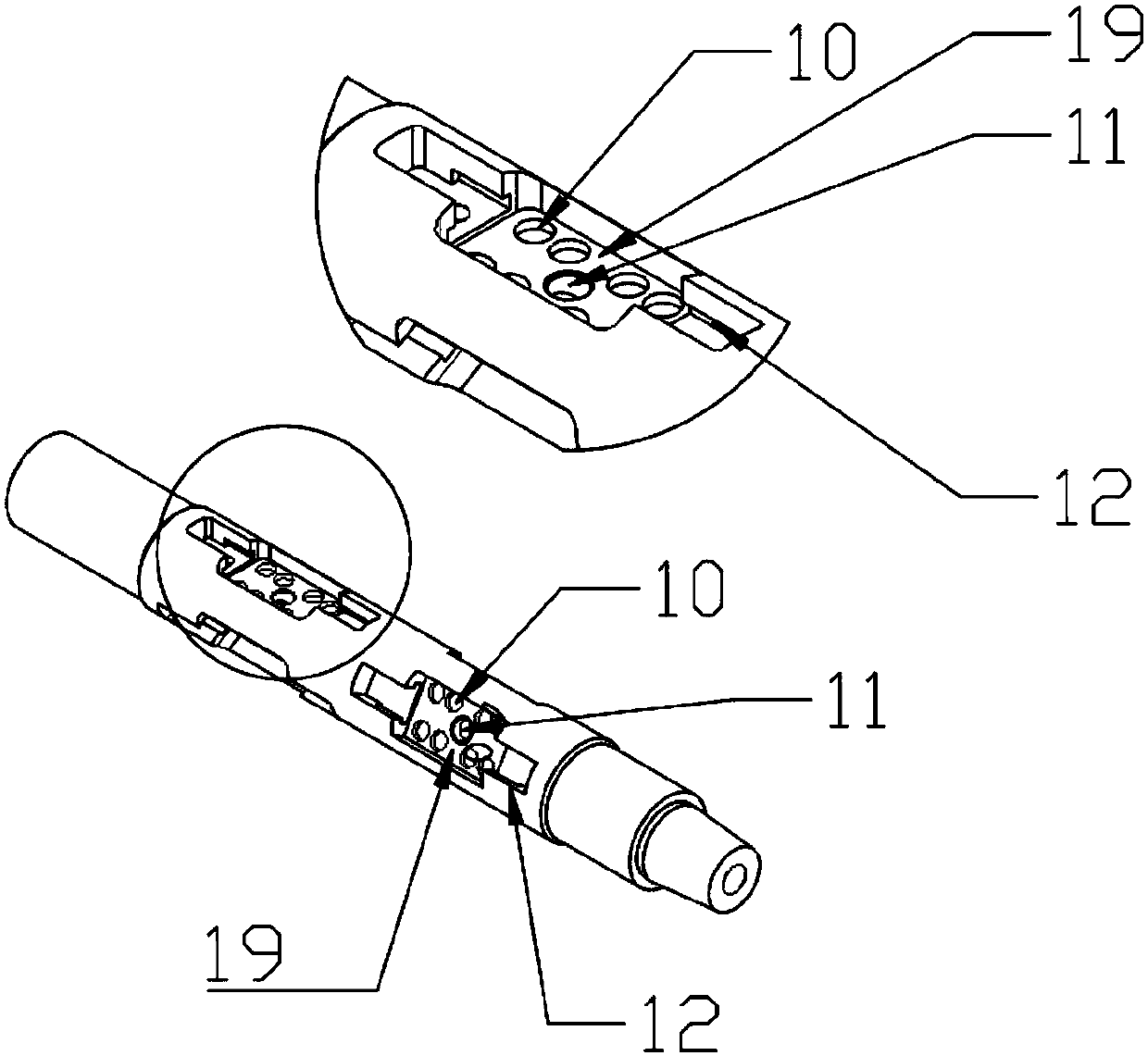

[0033] When designing this tool, first install the ratchet structure on the through hole 11 of the ratchet structure of the body 1. The ratchet structure is composed of an inner sleeve 5 and a pressure-bearing plug 6. The inner sleeve 5 is fixed on the body 1 with external threads. The bottom 26 faces the central lumen. In the initial state, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com