Ball supply and ball quantity checking device for bearing

A technology of inspection devices and balls, applied in bearing components, shafts and bearings, mechanical bearing testing, etc., can solve problems such as a lot of work time, productivity decline, delayed work time, etc., to reduce work time and labor, improve productivity, and ease The effect of manufacturing and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

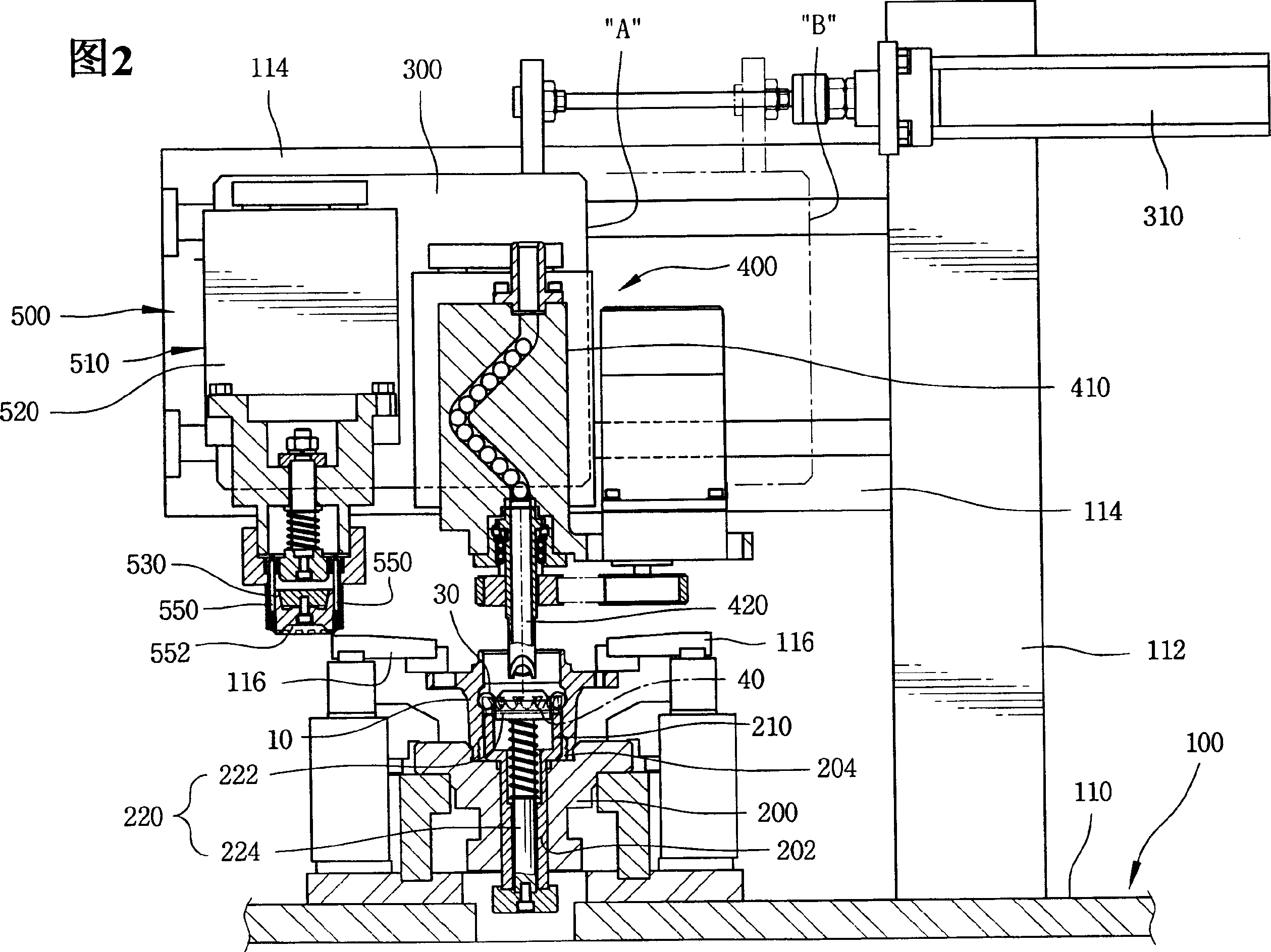

[0025] Next, preferred embodiments of the tool for supplying balls and checking the number of balls for automobile bearings according to the present invention will be described in detail with reference to the drawings.

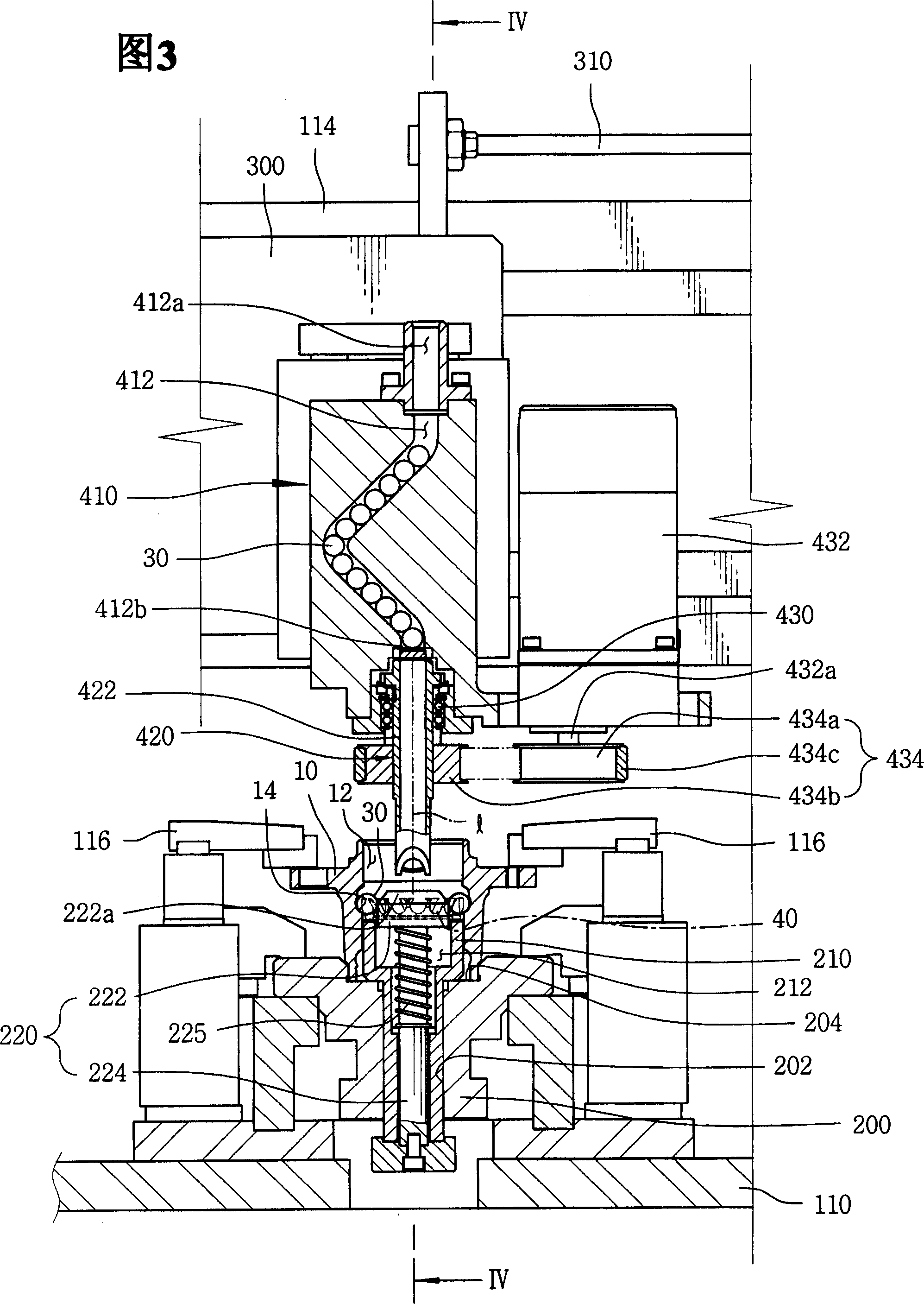

[0026] First, referring to FIG. 2 , the ball supply and ball quantity inspection tool according to the present invention has a frame 100 . The rack 100 has: a workbench 110 , a support column 112 vertically arranged on the workbench 100 , and a support arm 114 extending horizontally from the support column 112 to one side.

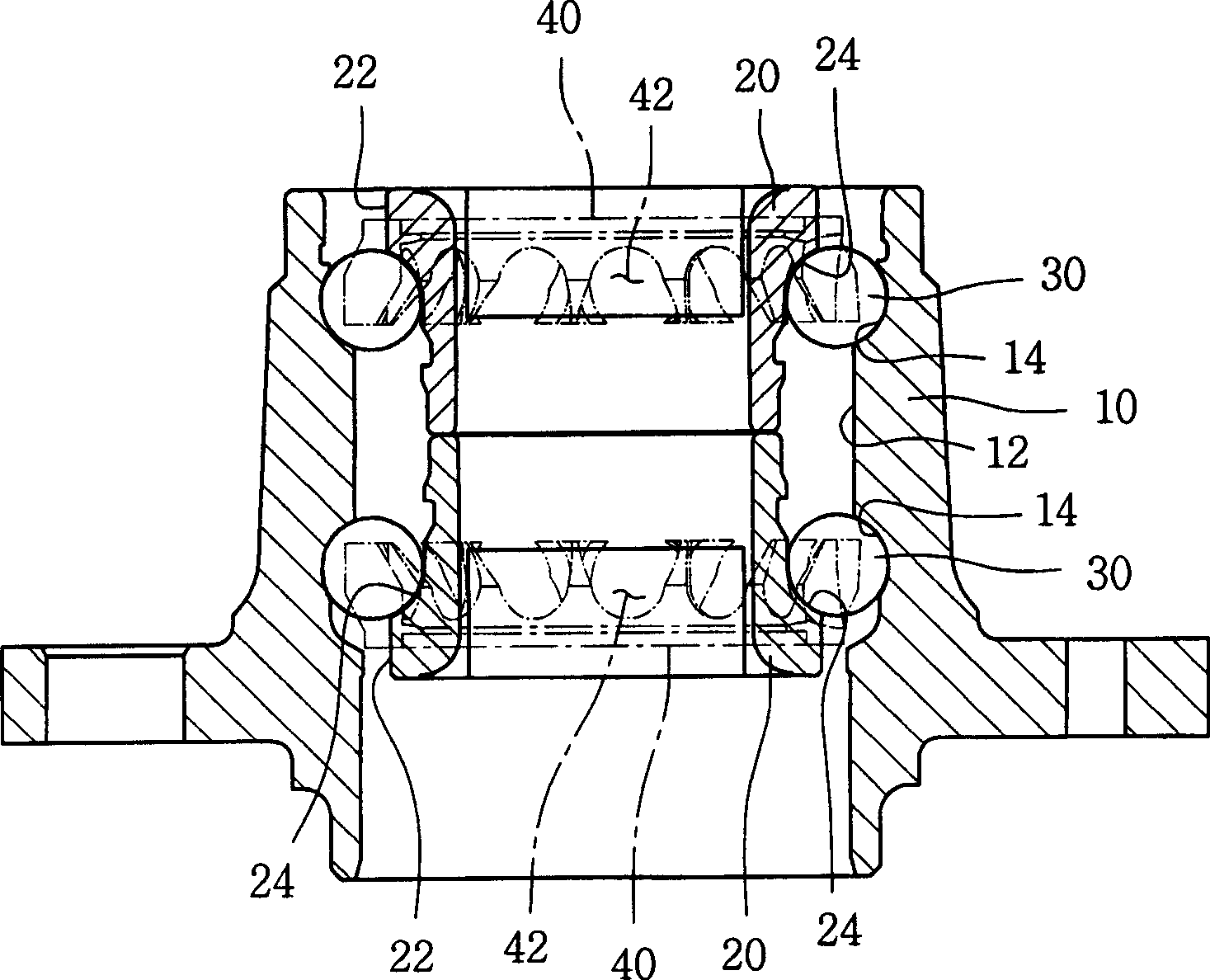

[0027] On the other hand, on the table 110 of the frame 100, a base 200 for supporting the outer ring 10 of the wheel bearing is provided. The base 200 , as shown in FIG. 3 , is fixed on the worktable 110 and has an inner circumference 202 , and a support groove 204 is formed on the upper end of the inner circumference 202 to vertically support the outer ring 10 .

[0028] Such a base 200 is configured to support the outer ring 10 . In p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com