Method and device for 10 kV electrified work for connecting lead of branch connecting circuit

A line-connecting, 1.10kv technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenience of live operators, difficult operation of operators, and high labor intensity, so as to eliminate habitual illegal operations, improve the reliability of power supply, The effect of saving tool usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

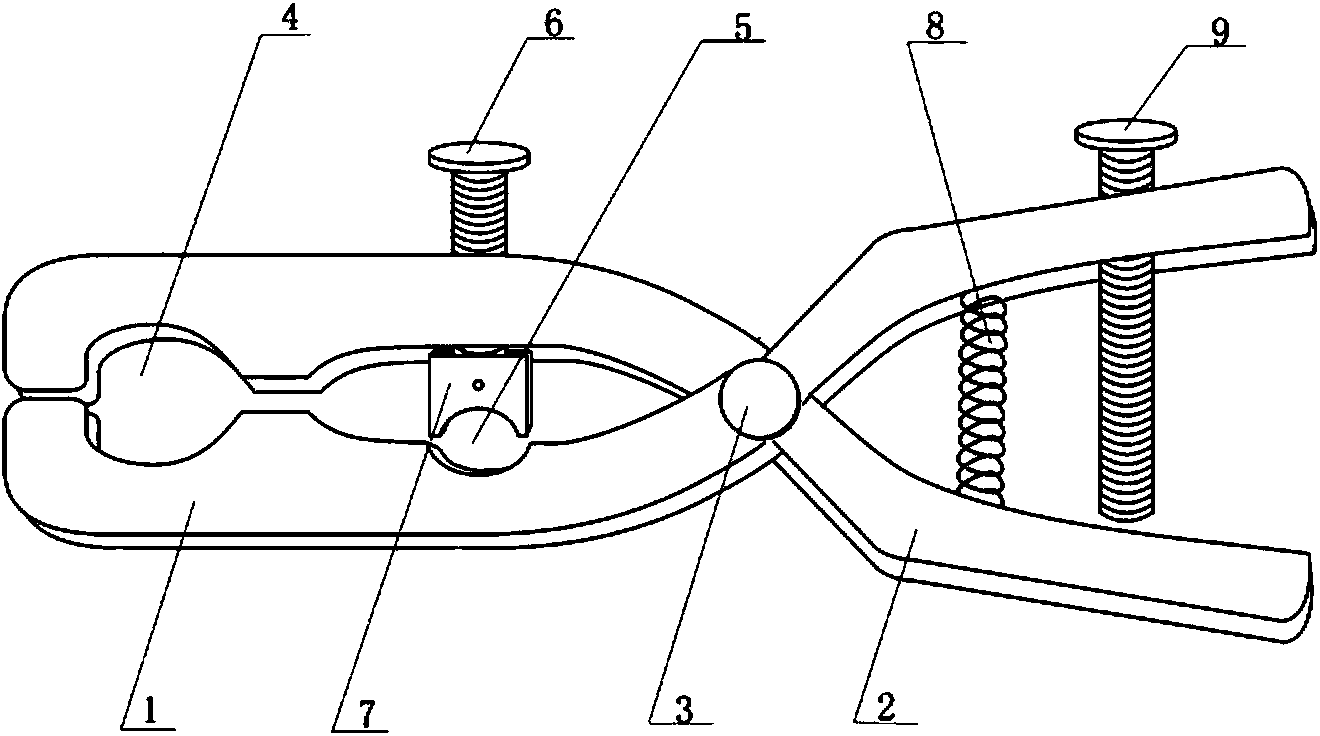

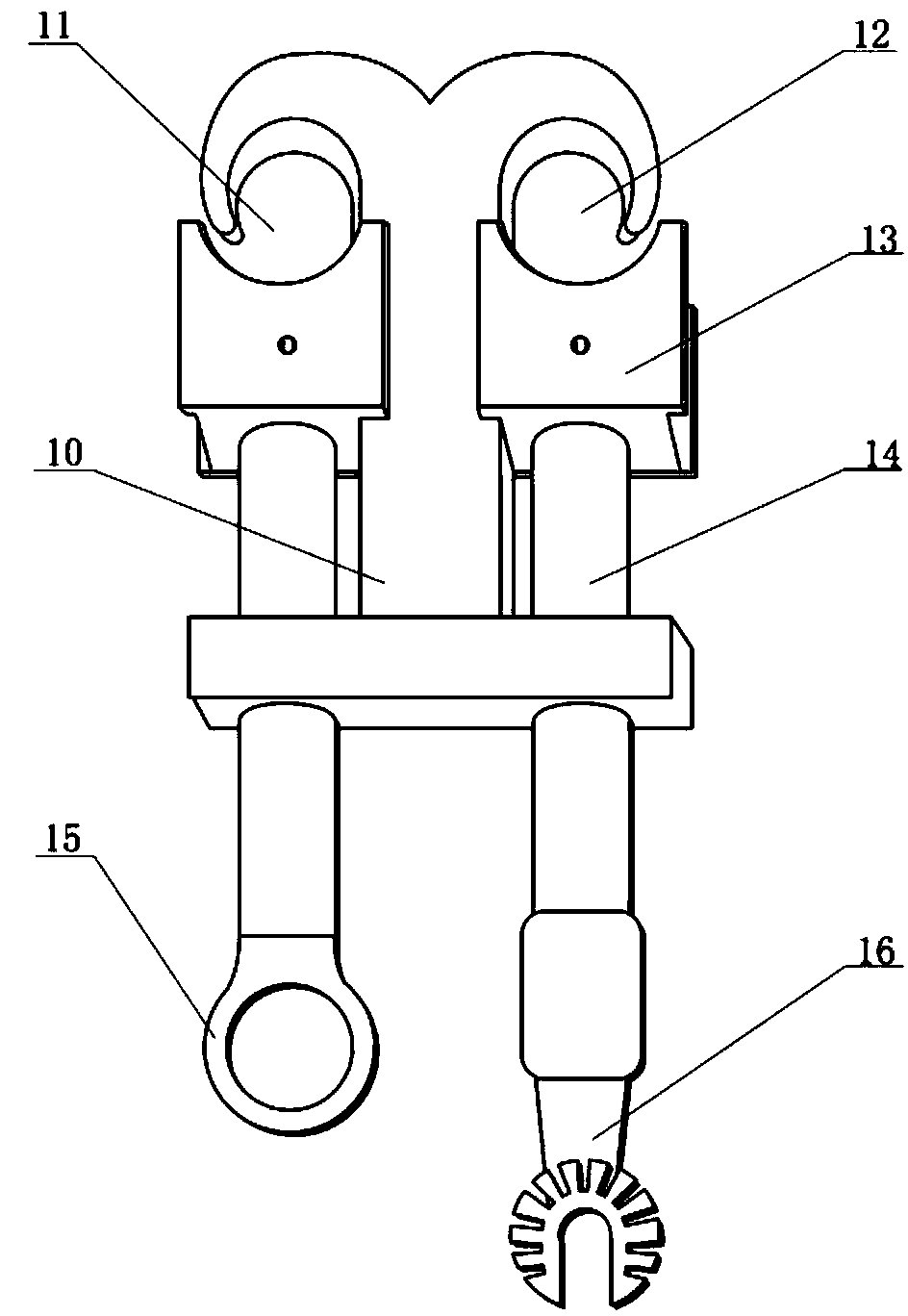

[0028] See figure 1 , is a schematic structural view of the lead wire insulation fixer of the present invention. See figure 2 , is a schematic view of the structure of the double-tighten type lead clamp of the present invention.

[0029] The operation method of the 10kV electrified connection branch line lead wire of the present invention adopts the lead wire insulating fixer to fix the lead wire and the main lead wire, and adopts the double-tightening type lead wire clamp to complete the lead wire overlapping operation, including the following steps:

[0030] 1) The electrician in the bucket operates the insulated bucket arm truck and enters the live working area;

[0031] 2) The electrician in the bucket adjusts the insulating bucket to the appropriate working position on the inner side of the branch line, and checks the parts that may be to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com