Square pile rotary drilling device for achieving square pore-forming and rotary drilling method thereof

A square and rectangular technology is applied in the field of square pile rotary excavation devices for realizing square holes, which can solve the problems of insecurity, the inability of rotary excavators to directly form square holes, and the low construction efficiency of square piles. Operational risks and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

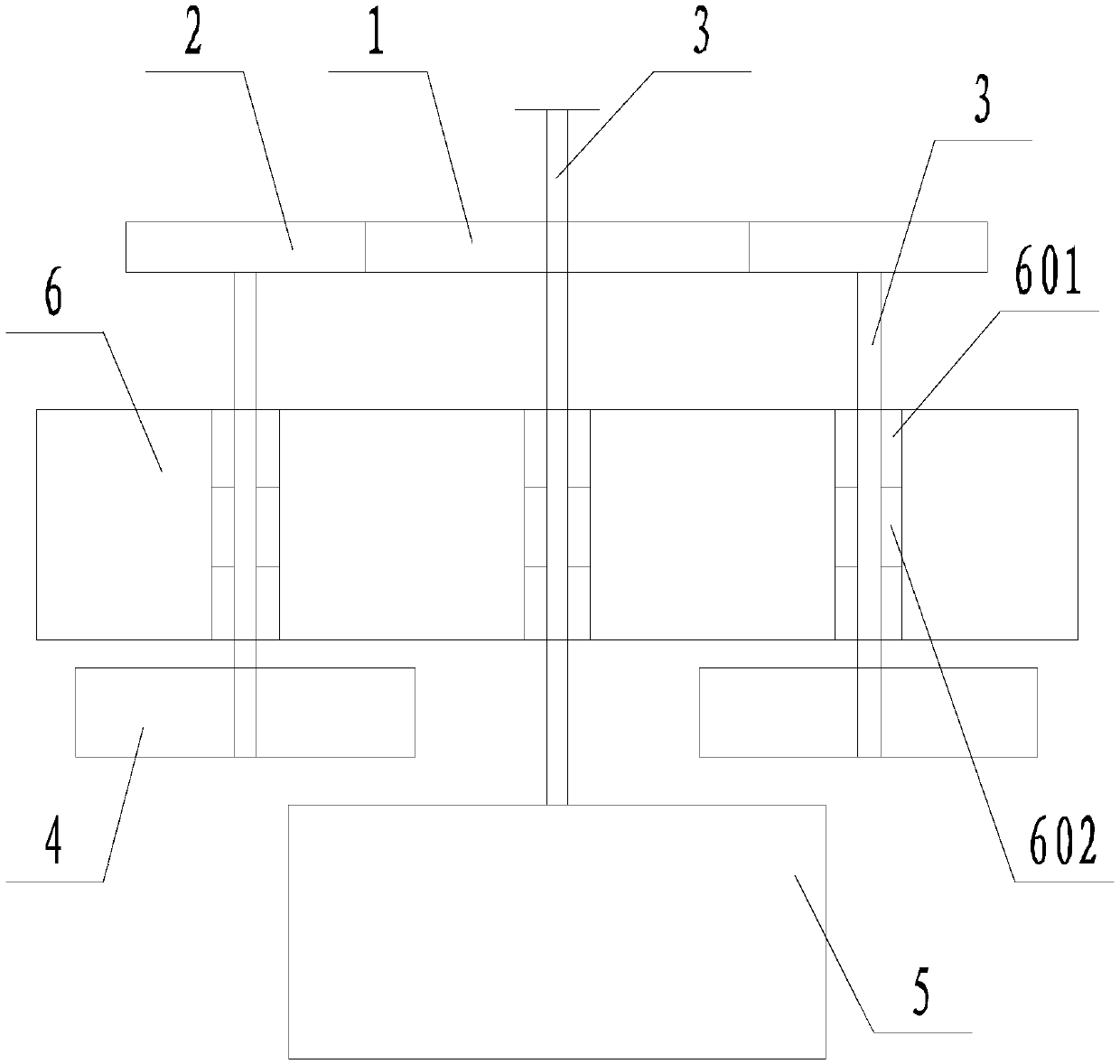

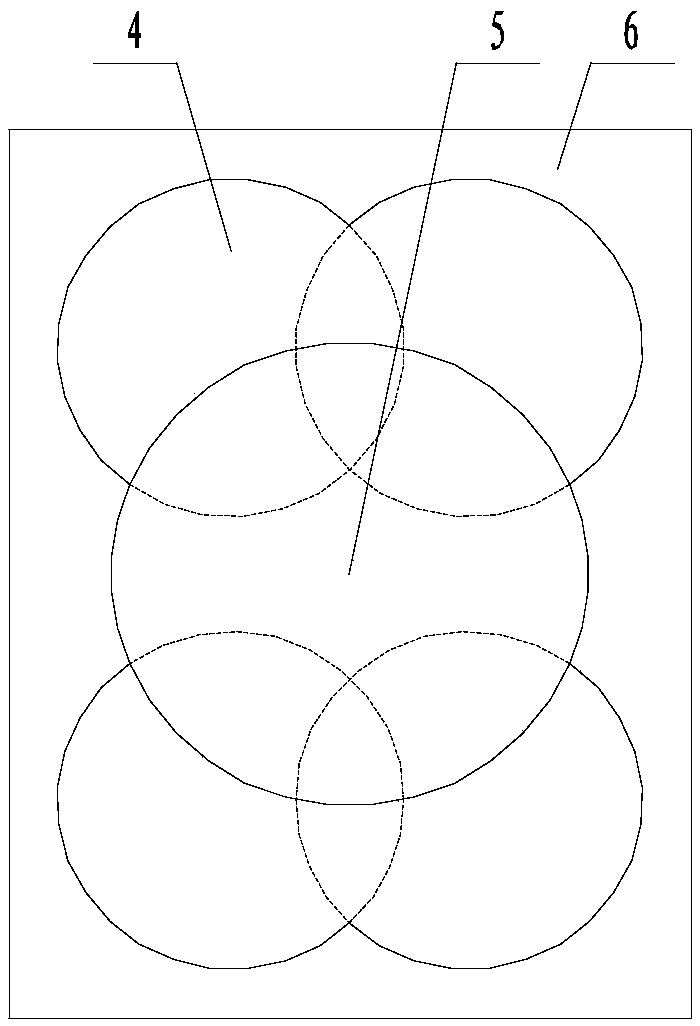

[0036] like figure 1 and figure 2 The shown a kind of square pile rotary digging device that realizes square hole formation, comprises rotating part one 1, several rotating parts two 2 that rotate with described rotating part one 1, described rotating part one 1, rotating part two 2 The rotating shafts are parallel to each other, and the rotating part one 1 drives the main drill bit 5 to rotate, and each rotating part two 2 drives an auxiliary drill bit 4 to rotate, and all auxiliary drill bits 4 are positioned above the main drill bit 5; The projection in the rotation plane of the drill bit 5 partially coincides with the main drill bit 5 ; it also includes a square scraper 6 located above the auxiliary drill bit 4 . In this embodiment, during drilling construction, the main drill bit must first contact the soil layer to form a corresponding main hole, and then the auxiliary drill bit touches the soil layer as it continues to descend. Partial overlap, so several auxiliary d...

Embodiment 2

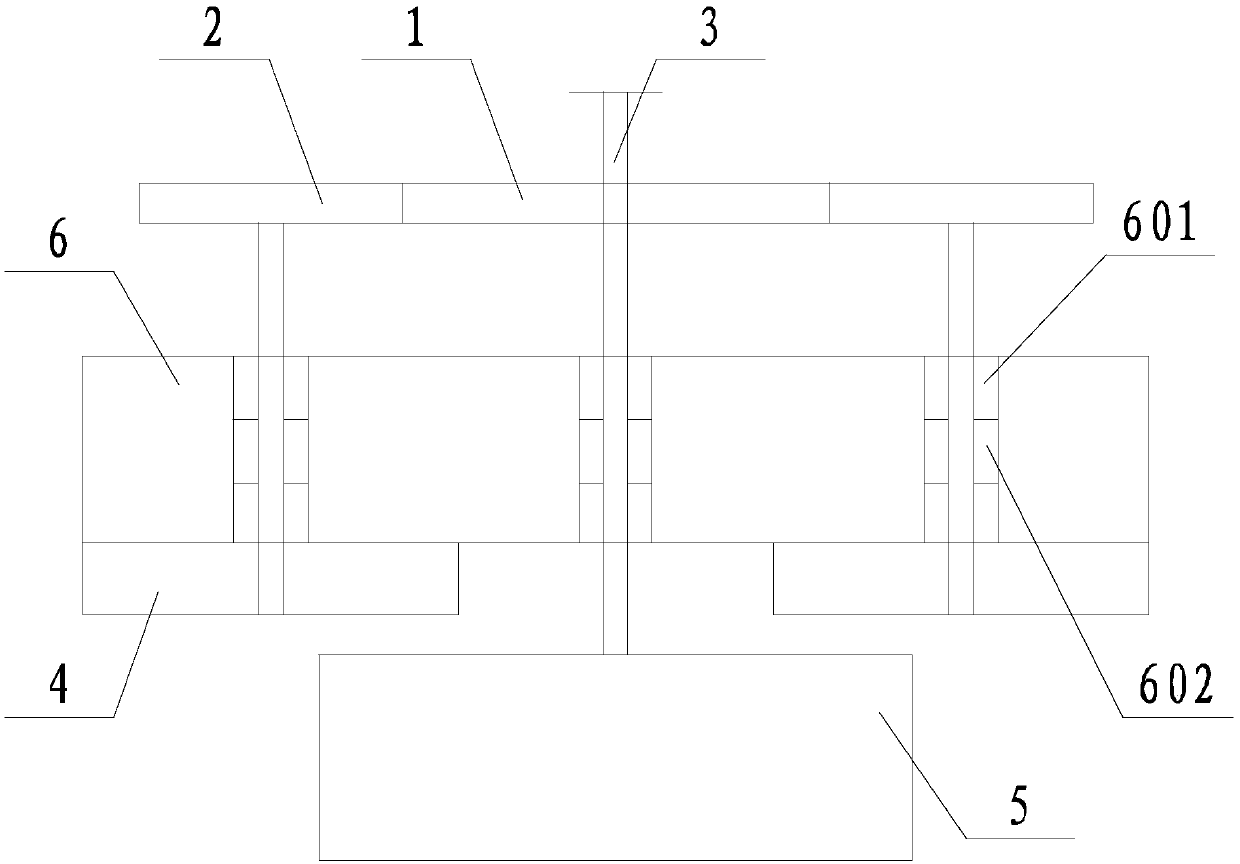

[0042] like Figure 3 to Figure 5 In the illustrated square pile rotary digging device for forming holes in a square shape, on the basis of Embodiment 1, the first rotating member 1 and the second rotating member 2 are located above the square scraping member 6 . The rotating part one 1 is the main gear, and the rotating part two 2 is the auxiliary gear meshed with the main gear. The drill bit 5 and the auxiliary drill bit 4 are connected, and the square scraper 6 does not rotate with the connecting rod 3 . The square scraper 6 is provided with a through hole 601 for the connecting rod 3 to pass through. The connecting rod 3 is covered with a bearing 602 , and the bearing 602 is fixed on the inner wall of the through hole 601 . There are four auxiliary drill bits 4 in total, and the centers of the four auxiliary drill bits 4 are in the same plane, and the centers of the four auxiliary drill bits 4 are four vertices of a rectangle. The projection of the center of the main dri...

Embodiment 3

[0044] like Image 6 As shown, in this embodiment, the main hole formed by the main drill bit 5 is inscribed on the opposite sides of the square formed by the projection of the square scraper 6. The hole formed by this embodiment is not a completely regular square hole, but For a nearly square cast-in-place hole, the square scraper 6 mainly plays the role of leveling and trimming the hole wall. Although the square shape of this structure is irregular, compared with the conventional cylindrical pile foundation, the approximately square cast-in-place pile foundation can still improve the effect of strengthening the foundation and adapt to more complex and dangerous geological environments. It also realizes the direct operation of the rotary excavator, and still overcomes many disadvantages of manpower digging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com