Mechanical quick-hole-formation construction method for improved simple rectangular anti-slide pile

A construction method and technology of anti-slide piles, which are applied to drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., can solve the problems of low efficiency of manual digging piles breaking into rock, slow construction progress of manual digging piles, and high cost. The difficulty of hole construction and other problems have been achieved, and the effect of promoting the scope of use, being suitable for popularization and use, and reducing hidden dangers of operation safety has been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

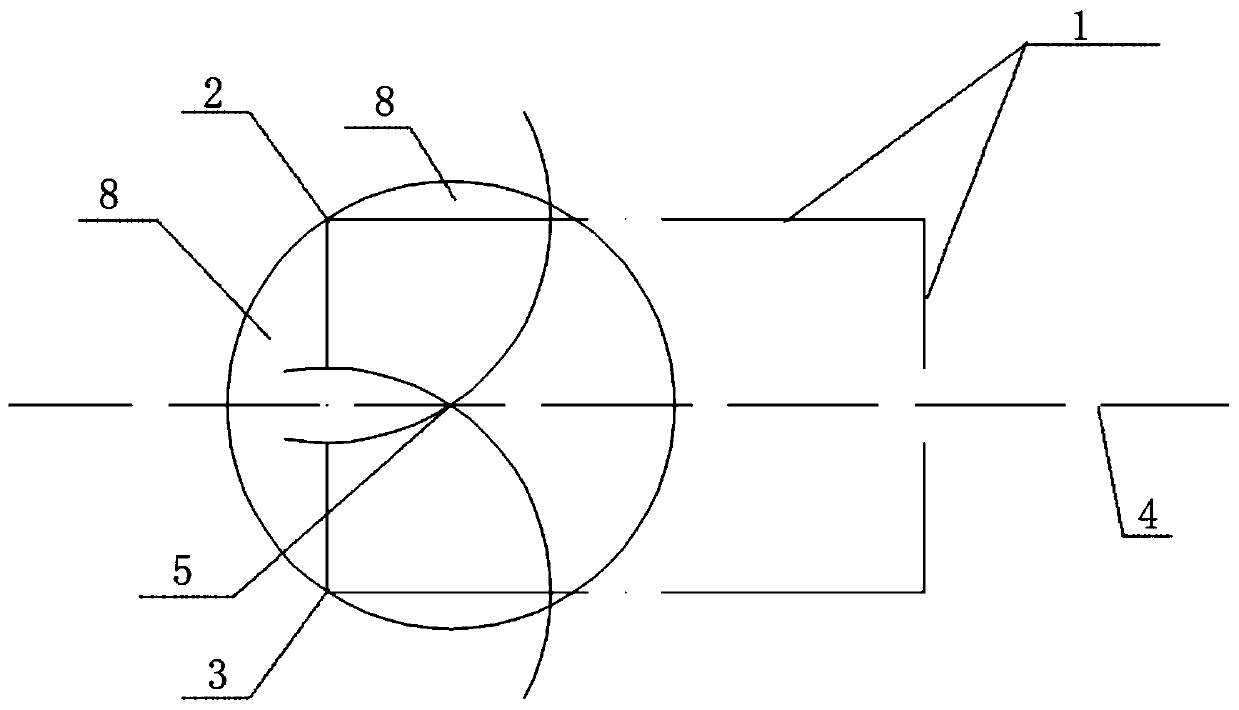

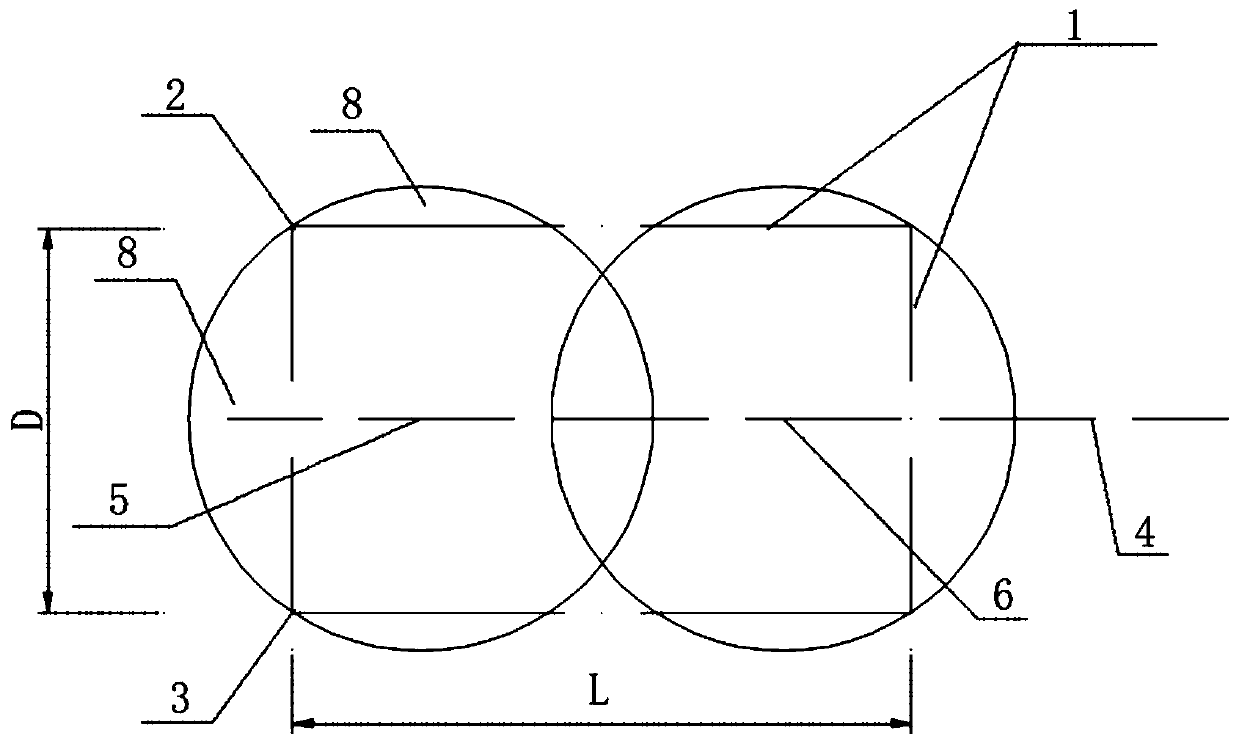

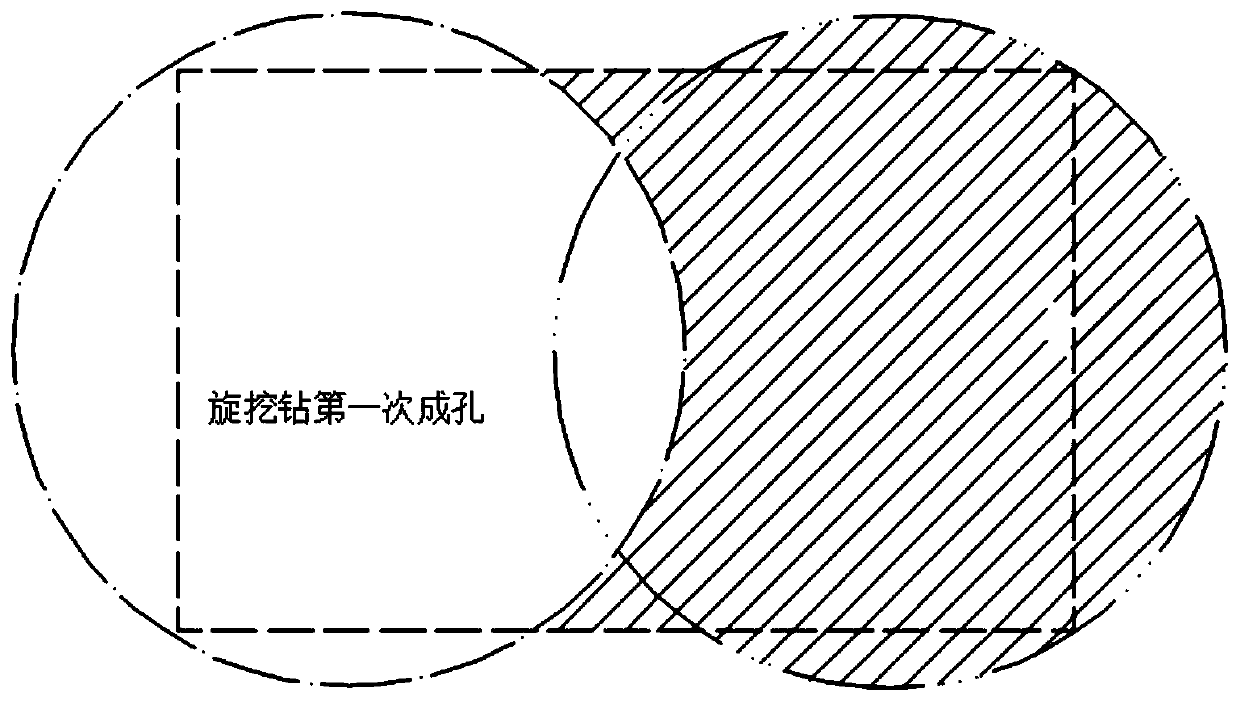

[0052] The specific implementation of the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0053] Taking the landslide prevention project as an example, the slope support structure is supported by a pile plate retaining wall, and the pile foundation is a rectangular anti-slide pile with a size of 1.5m×2.4m. The construction method is shown in Figure 1~ Figure 6 As shown, the following steps are generally included:

[0054] A. Anti-slide pile hole setting out positioning

[0055] A.1 Determine the contour line 1 of the rectangular pile hole 1.5m×2.4m;

[0056] A.2 According to the fact that the length of the short side of the contour line of the rectangular pile hole is D=1.5m, and the diameter of the hole formed by the medium-sized or large-scale rotary drilling rigs on the market is 0.8-2.5m, the diameter of the drill bit of the rotary drilling machine is determined to be d 1 =1.8m;

[0057] A....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com