Transporting device for CRH5A motor train unit fifth-level-overhaul electrical cabinet

A technology for transportation devices and EMUs, applied in transportation and packaging, manual transportation devices, etc., can solve the problems of high labor intensity and low production efficiency, and achieve the effects of reducing labor intensity, improving production efficiency, and avoiding operational risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

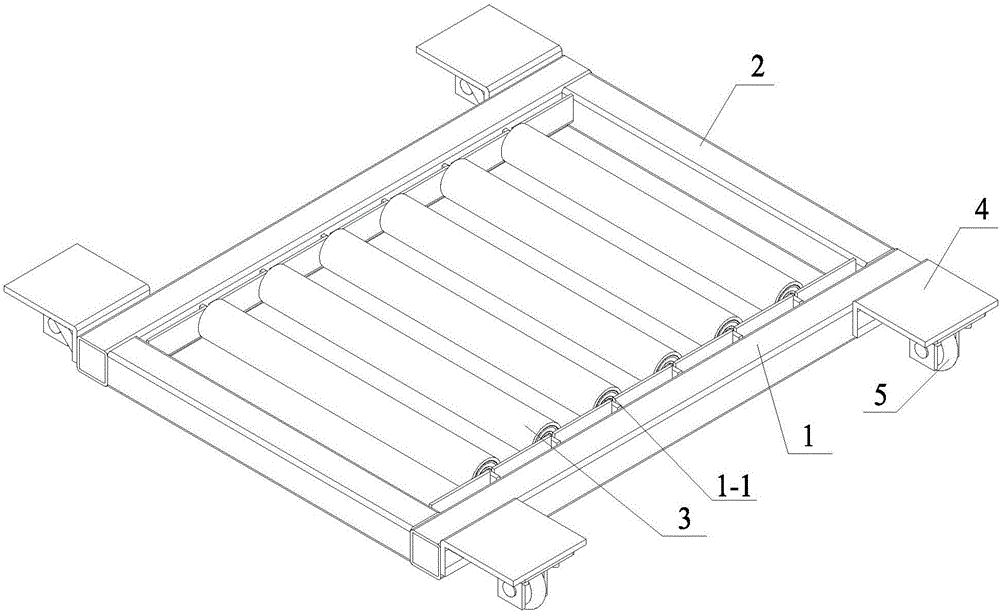

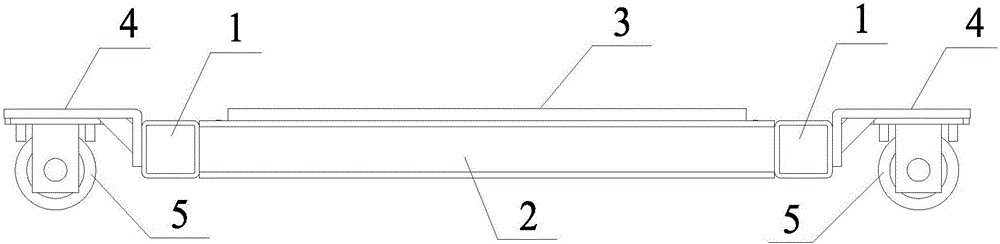

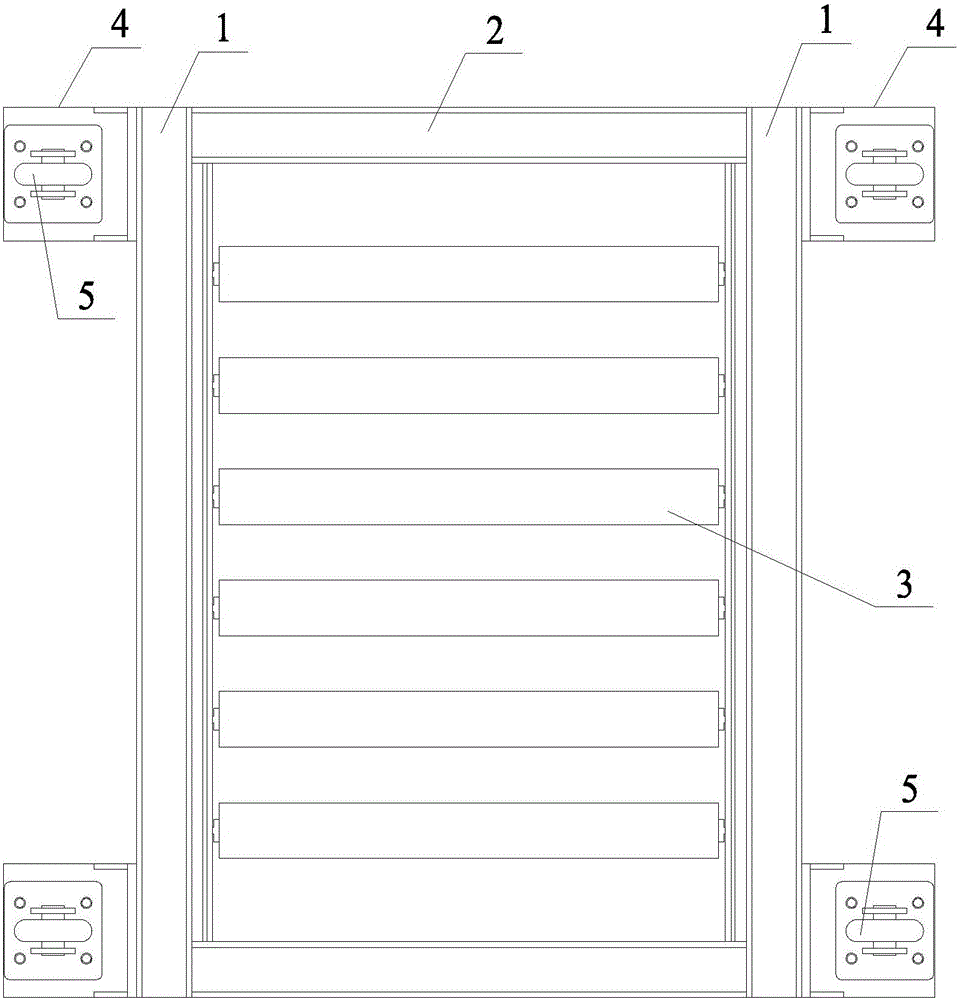

[0013] Such as Figure 1 to Figure 4 As shown, the CRH5A type EMU fifth-level repair electrical cabinet transportation device of the present invention is made of carbon steel as a whole, and the overall height is 300mm. The transportation device includes two longitudinal beams 1, two beams 2, six roller bars 3, four L-shaped support plates 4 and four universal wheels 5; two longitudinal beams 1 and two beams 2 are vertically welded in pairs A rectangular underframe, six grooves 1-1 are arranged at equal intervals on the inner sides of two longitudinal beams 1, and the two ends of the rotating shafts of the six roller bars 3 are correspondingly placed in twelve grooves 1-1. The beam 1 is connected by rolling; the four L-shaped support plates 4 are respectively located at the four corners of the rectangular underframe, and are correspondingly welded on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com