Construction method for conducting pipe interior under-pressure plugging on production pipe string

A construction method and a technology for producing pipe strings, which are applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., and can solve the problems of tubing plug midway setting, high operating cost, and high safety requirements for well control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the following embodiments do not limit the present invention by any means.

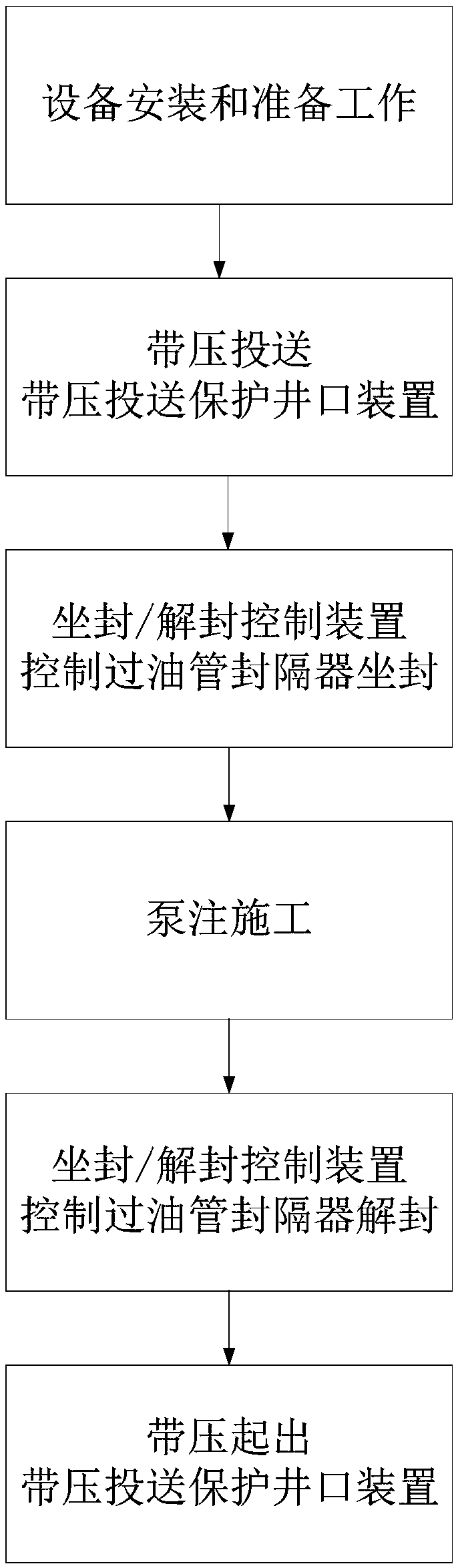

[0030] like figure 1 As shown in the figure, the construction method for in-pipe plugging with pressure in the production string is realized through five steps of feeding under pressure, setting the packer, pumping construction, unsealing the packer, and pulling out under pressure;

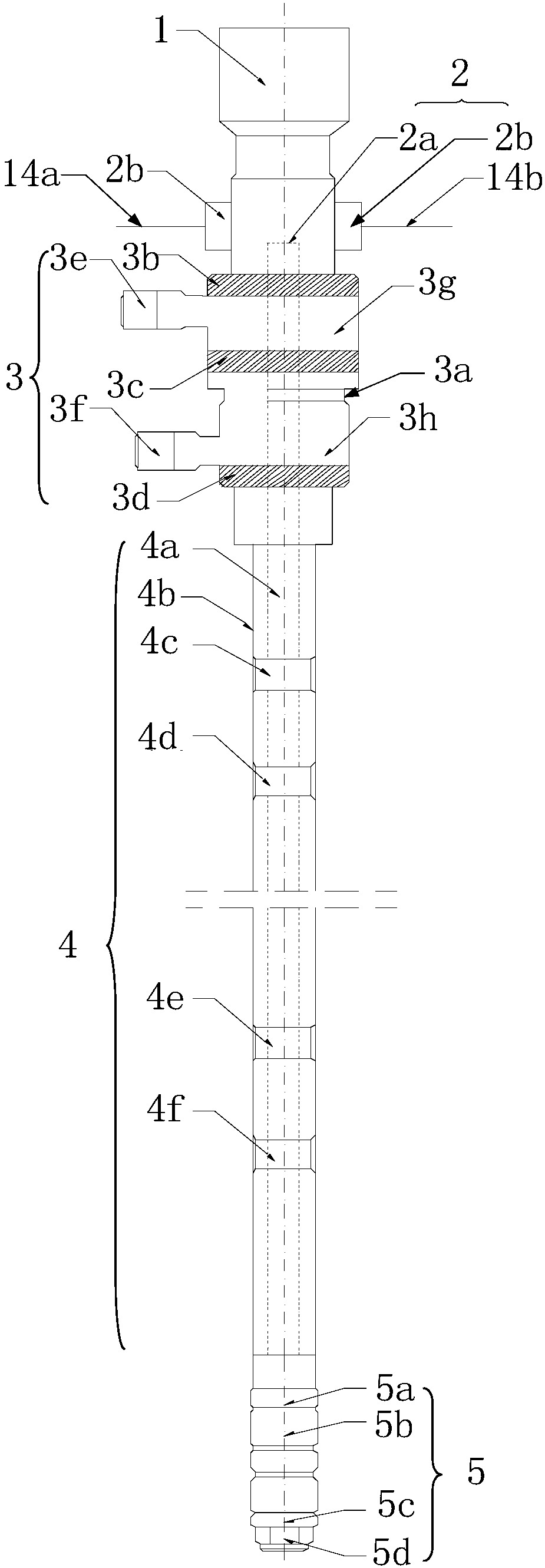

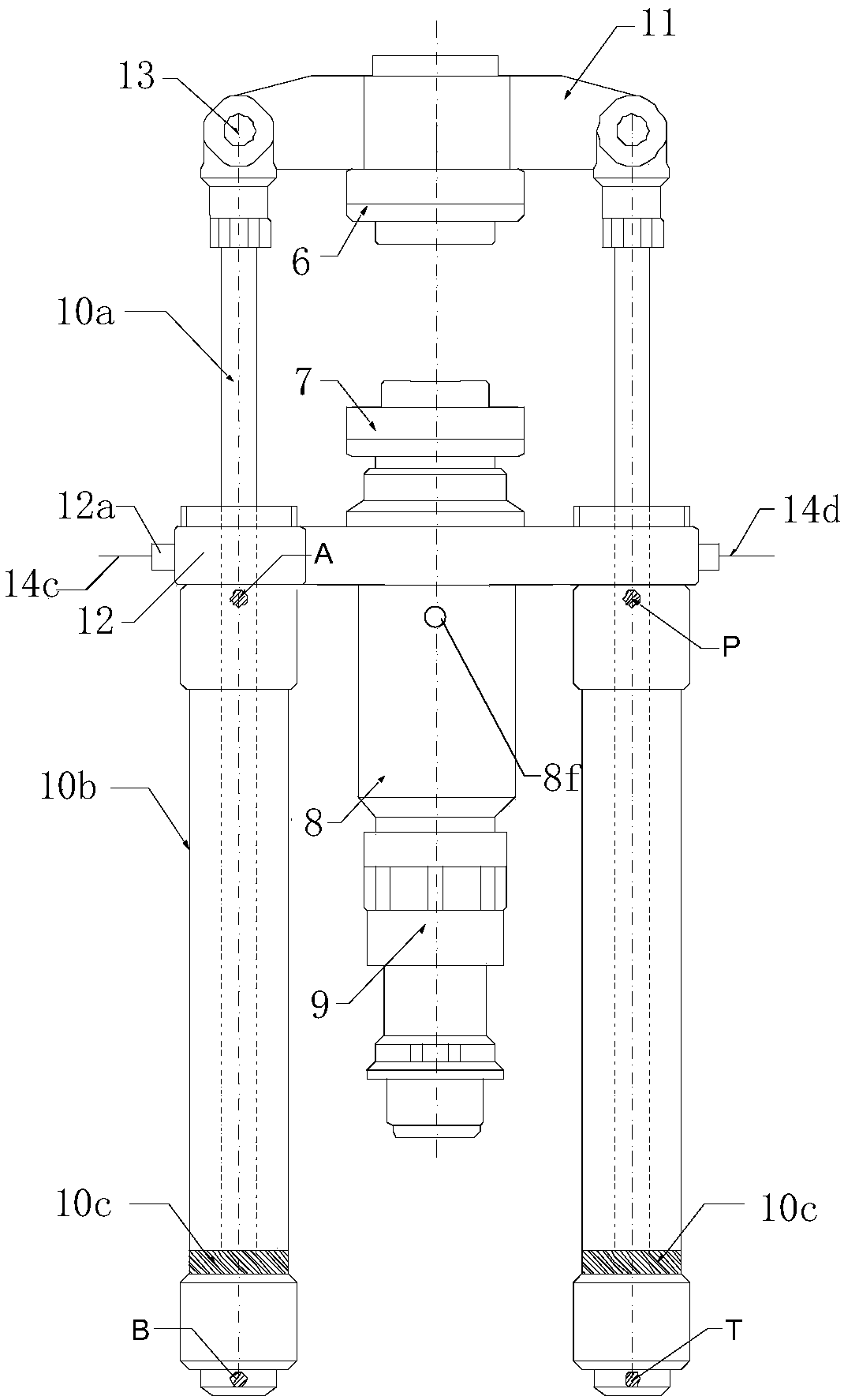

[0031] Among them, such as Figures 2 to 3 As shown in the figure, the wellhead device for under-pressure delivery protection includes an upper mechanism and a lower mechanism that can be inserted into one piece; wherein, the upper mechanism includes an upper joint 1, an anti-falloff pipe 2, a delivery oil pipe 4, a setting / unsealing The control device 3 and the oil pipe packer 5; the lower mechanism includes a floating locking mechanism 6, a fixed locking mechanism 7, a double-stage blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com