Well killing treatment method for well kick in process of pulling out of hole

A treatment method and well killing technology, which is applied in the field of well killing treatment of well kicks during drilling and tripping, can solve the problems that conventional well killing methods cannot be used, improve the probability of successful well killing, simple calculation process, and unique operation process complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

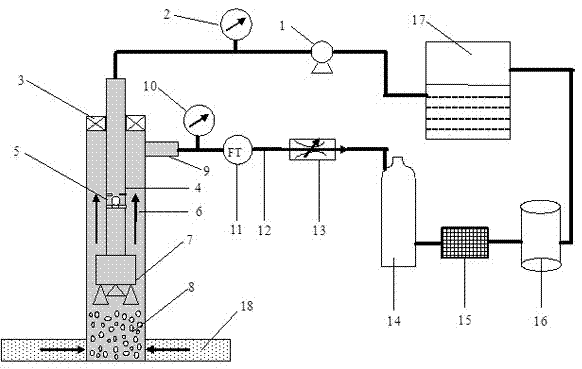

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

[0041] as attached figure 1 As shown, the drilling equipment includes drilling fluid, which is sprayed from the surface drilling pump 1 through the standpipe pressure gauge 2, blowout preventer group 3, drill string 4, and back pressure valve 5 to the drill bit 7, and then the drilling tool and the wellbore ring Empty 6, cross 9, wellhead pressure gauge 10, mass flow meter 11, throttle manifold 12, throttle valve 13, gas-liquid separator 14, vibrating screen 15, vacuum degasser 16 return to mud pool 17.

[0042] After drilling to the gas layer 18, during the drilling process, due to the underbalance of the bottom hole caused by stopping the pump and suction, a well kick was found. At this time, the well killing treatment method includes the following steps:

[0043] 1. Shut down the well and connect the mass flowmeter in the choke manifold

[0044] When a well kick o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com