Vertical well orientated hydraulic jet multi-stage fracturing method for oil and gas well

A technology for hydraulic jetting and oil and gas wells, which is applied in wellbore/well components, earthwork drilling and production, and production fluids, etc. It can solve problems such as low perforation efficiency and large bending friction, and achieve the effect of saving development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The directional hydraulic jet multi-stage fracturing method of oil and gas well vertical wells of the present invention comprises the following steps:

[0026] Step 1: Prepare the wellbore, wash the well, kill the well, and scrape the well;

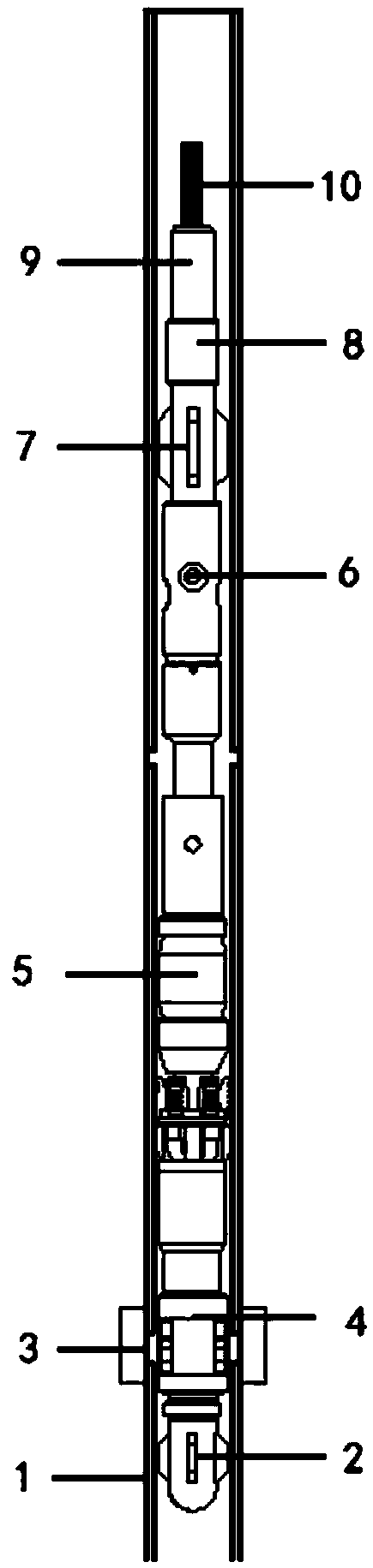

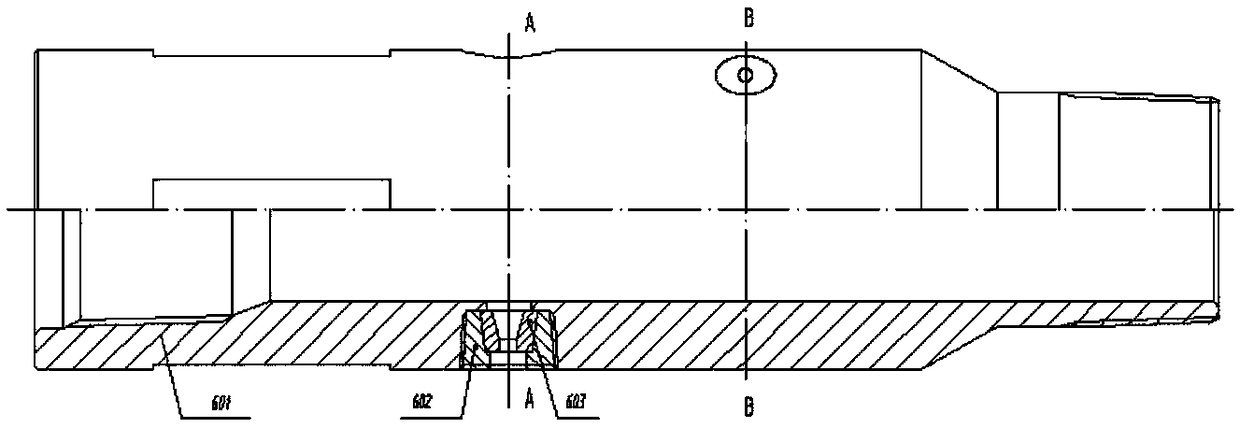

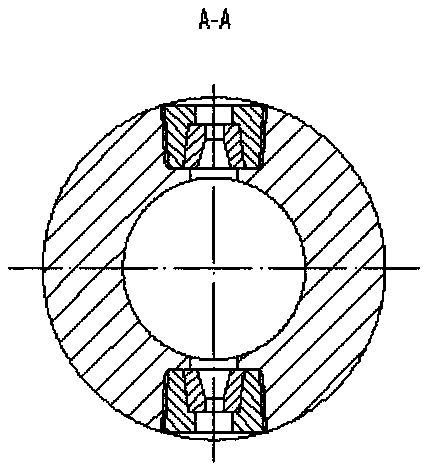

[0027] Step 2: At the tail end of the tubing, connect the guide head, the rotatable mechanical casing collar positioner, the repeatable setting tool, the directional hydraulic spray gun, the centralizer, the safety joint, the orientation short, and the tubing. Hydraulic jet staged fracturing construction string to the wellhead;

[0028] Step 3. After the pipe string enters the well, use the rotatable mechanical casing collar locator to precisely locate the directional hydraulic spray gun to determine the sandblasting perforation position;

[0029] Step 4: After the location of sandblasting and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com