Unidirectional temporary plugging agent for natural gas wells and application method thereof

An application method and technology of temporary plugging agent, applied in the direction of chemical instruments and methods, composition of drilling holes, etc., can solve the problems of impossibility, complete removal of blockages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

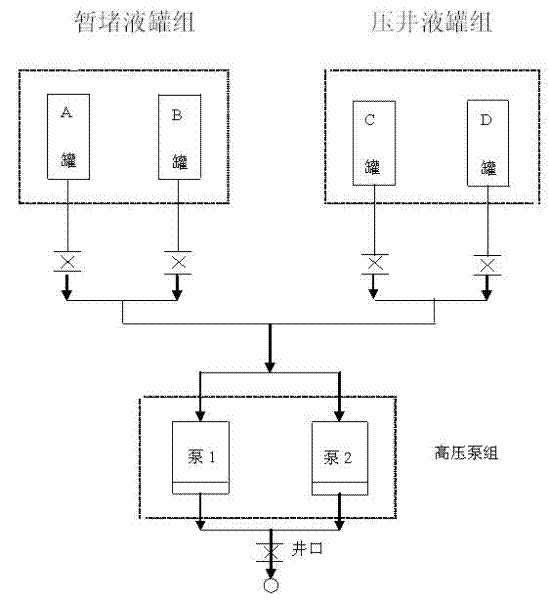

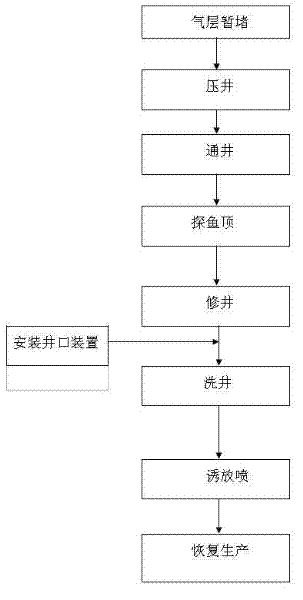

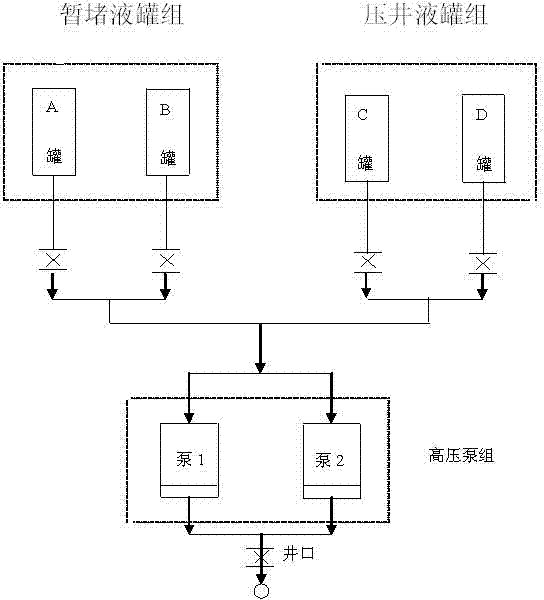

Image

Examples

Embodiment 1

[0018] Weigh 20 - 6000g of 22% acrylamide aqueous solution (you can also make acrylamide, water and other reactants directly into a mixed solution without pre-preparing acrylamide aqueous solution), tetraallyl ammonium bromide 2.0g, Na 2 CO 3 300g, activated clay 300g, stirred and dispersed for 60 minutes, heated to 40°C, filled with nitrogen for 30 minutes, added initiator k 2 S 2 o 8 -NaHSO 3 5-6g polymerized. After 2 hours of polymerization, the polymerized elastic colloid was kept at 85° C. for 8 hours. Cut the heated colloid to a length of 0.5 ~ The 1.0mm blocks were dried to obtain dry powder. Take 2000g of the dry powder prepared by the above method, add 200g of polycondensed propylene oxide-dimethylamine and 20g of o-phenylenediamine, stir and infiltrate for 2 hours to obtain the finished product.

Embodiment 2

[0020] Weigh 5000g of 20-22%% acrylamide aqueous solution, 1g of N, N-methylenebisacrylamide, 300g of α-hydroxysulfonate, activated silica 200g, stirred and dispersed for 60 minutes, heated to 30°C, filled with nitrogen for 30 minutes, added initiator k 2 S 2 o 8 -NaHSO 3 5-6g polymerized. After polymerizing for 1 hour, the polymerized elastic colloid was kept at a constant temperature of 70°C for 10 hours. Cut the heated colloid to a length of 0.5 ~ The 1.0mm blocks were dried to obtain dry powder. Get 1000g of dry powder worth the above method. Add 200g of polycondensed propylene oxide-dimethylamine and 10g of o-phenylenediamine to the dry powder, stir and infiltrate for 2 hours to obtain the finished product.

Embodiment 3

[0022] Weigh 7500g of 20-22% acrylamide aqueous solution, 5g of divinylbenzene, 500g of sultone, 500g of active silicon dioxide, stir and disperse for 60 minutes, heat to 30°C, fill with nitrogen for 30 minutes, add the initiator Na 2 S 2 o 8 -NaHSO 3 8-10g polymerized. After 3 hours of polymerization, the polymerized elastic colloid was kept at 90° C. for 6 hours. Cut the heated colloid to a length of 0.5 ~ The 1.0mm blocks were dried to obtain dry powder. Take 3000g of dry powder worth the above method, add polycondensed propylene oxide-dimethylamine 200g, o-phenylenediamine 10g, stir and infiltrate for 2 hours to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com