Automic control system for throttle well killing

An automatic control system, choke and kill technology, applied in the direction of fluid pressure control, control/regulation system, non-electric variable control, etc., can solve problems such as downhole pressure fluctuations, affecting the success rate of well killing, and bottom hole pressure reduction , to achieve the effect of improving the success rate of well killing and avoiding downhole pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

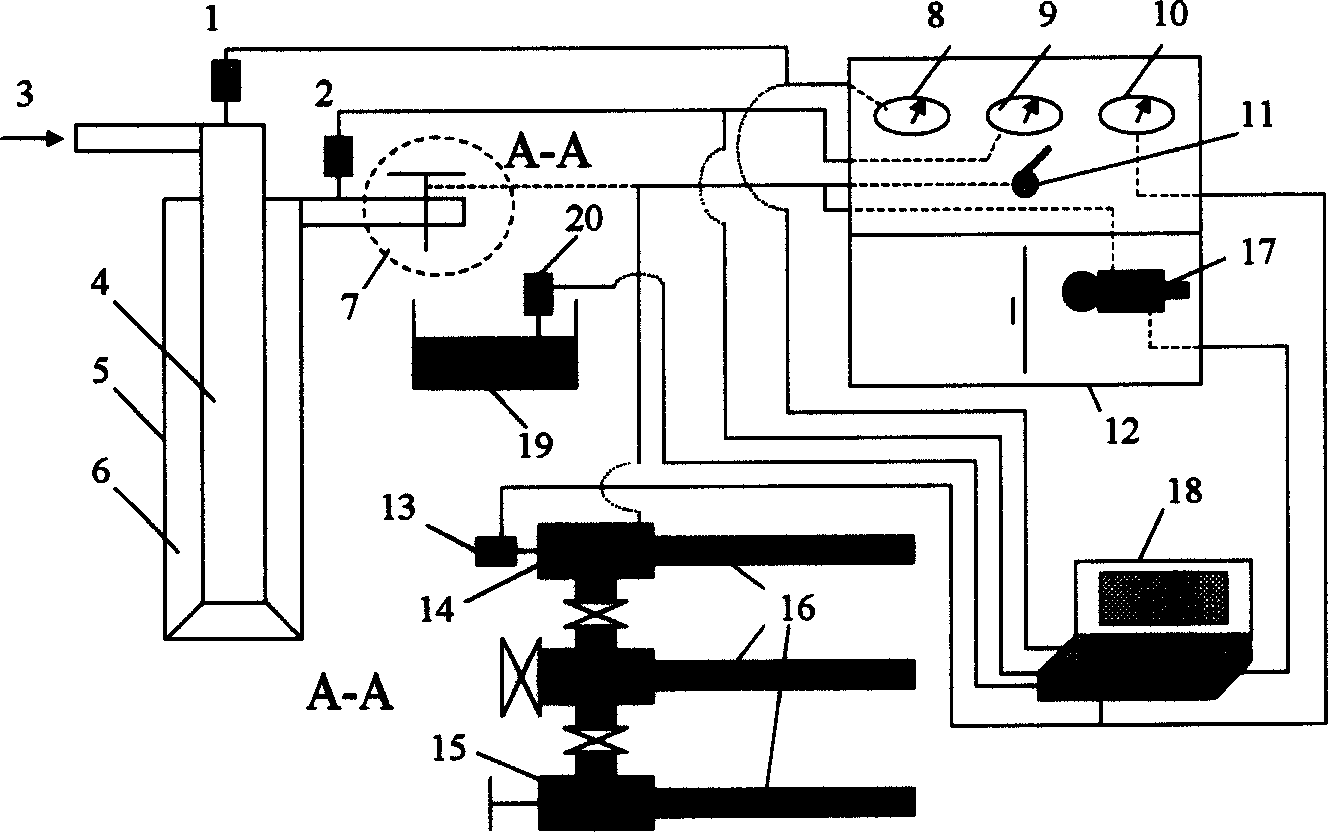

[0012] In Fig. 1, the killing fluid (3) enters the annulus (6) through the drill string (4) and returns to the mud pool (19) through the choke manifold (7) in the borehole (5) to form a circulation. The vertical pressure sensor (1) on the drill string is connected with the vertical pressure gauge (8) on the throttle control box (12) and the computer (18), and the casing pressure sensor (2) is connected with the casing pressure gauge ( 9) Connected to the computer, the mud tank liquid level sensor (20) is connected to the computer, the valve position sensor (13) is connected to the computer and the valve position opening meter (10) on the throttle control box, in the throttle control box, The manual three-position four-way valve (11) is connected in parallel with the electric three-position four-way valve (17), the oil circuit output end is connected with the hydraulic throttle valve (14), and the control end of the electric three-position four-way valve is connected with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com