Integrated oil casing head

An oil-casing, integral technology, applied in the field of integral oil-casing head, can solve the problems of time-consuming, cost, safety risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

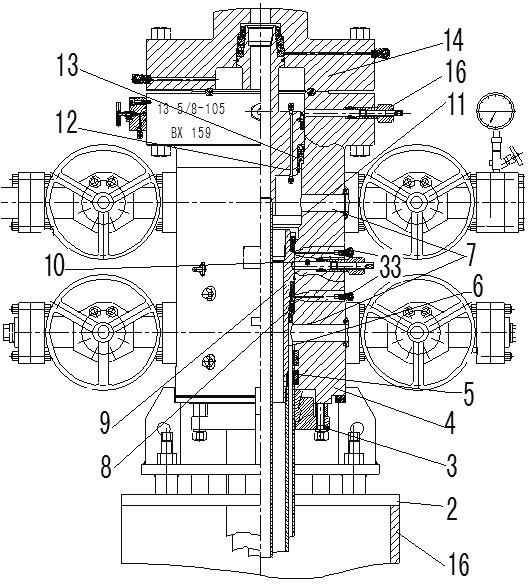

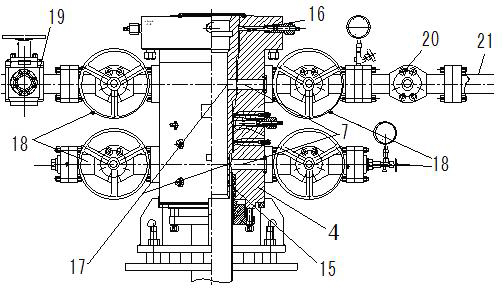

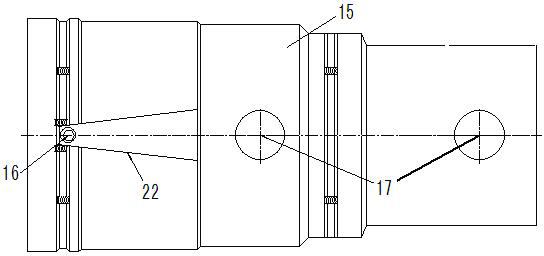

[0018] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0019] Such as figure 1 As shown, the structure of the wellhead device of the present invention includes a bracket 2 welded to the upper port of the catheter 1. The upper end of the bracket 2 is kept in contact with the body 4 of the wellhead device through a clamp block. The inner cavity of the body 4 is provided with three steps, from below From the top, there are the technical casing hanger step 8, the pressure test step 11, and the tubing hanger step 13. The main body 4 is provided with a flat head screw 16, two sets of side diameter holes 7, and a top Wire 10 and two pressure test holes 33; the inner circumference of the lower section of the body 4 is covered with a surface casing 6, and the lower end of the body 4 is equipped with an inverted slip 3, which is used to hang the surface casing 6, and the inverted slip 3 The circle is tightly sleeved with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com