Orchard tumbril

A technology for fertilizing vehicles and orchards, applied in fertilization devices, fertilizer distributors, and agricultural gas emission reduction, etc. It can solve the problems of unsafe working environment, single function of perforated fertilizer applicators, and boring labor content, etc., to achieve The effect of simple structure, fast fertilization speed and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

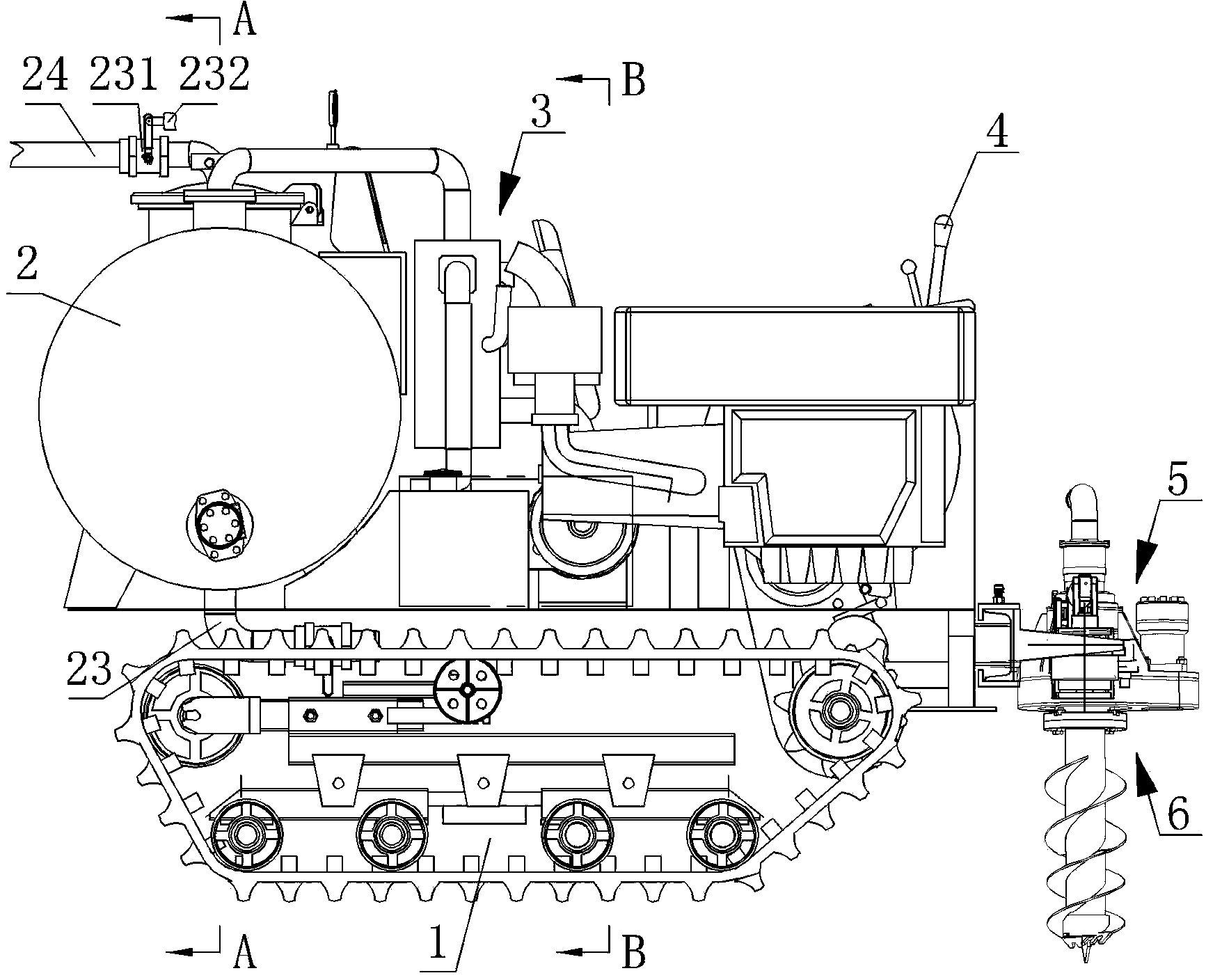

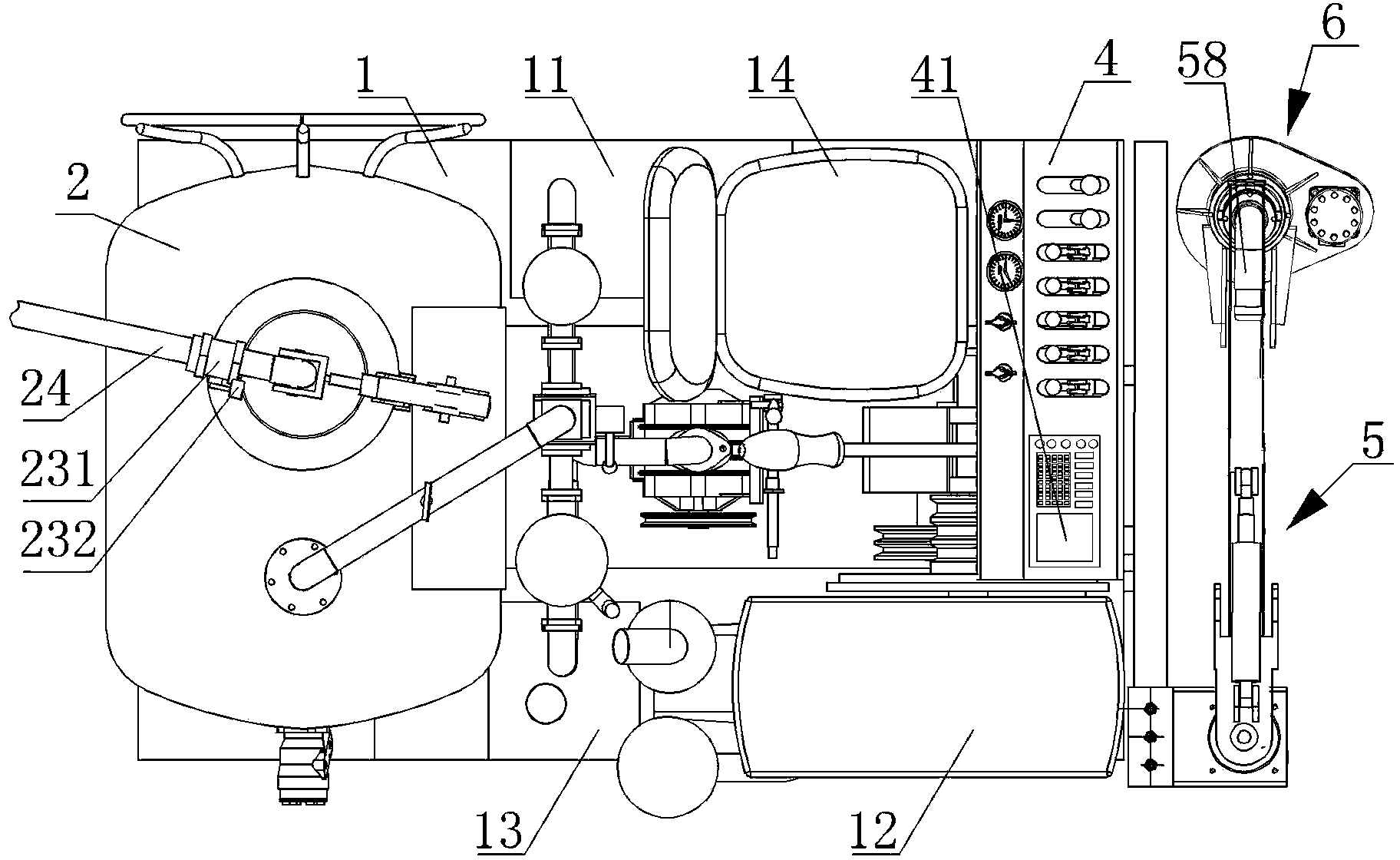

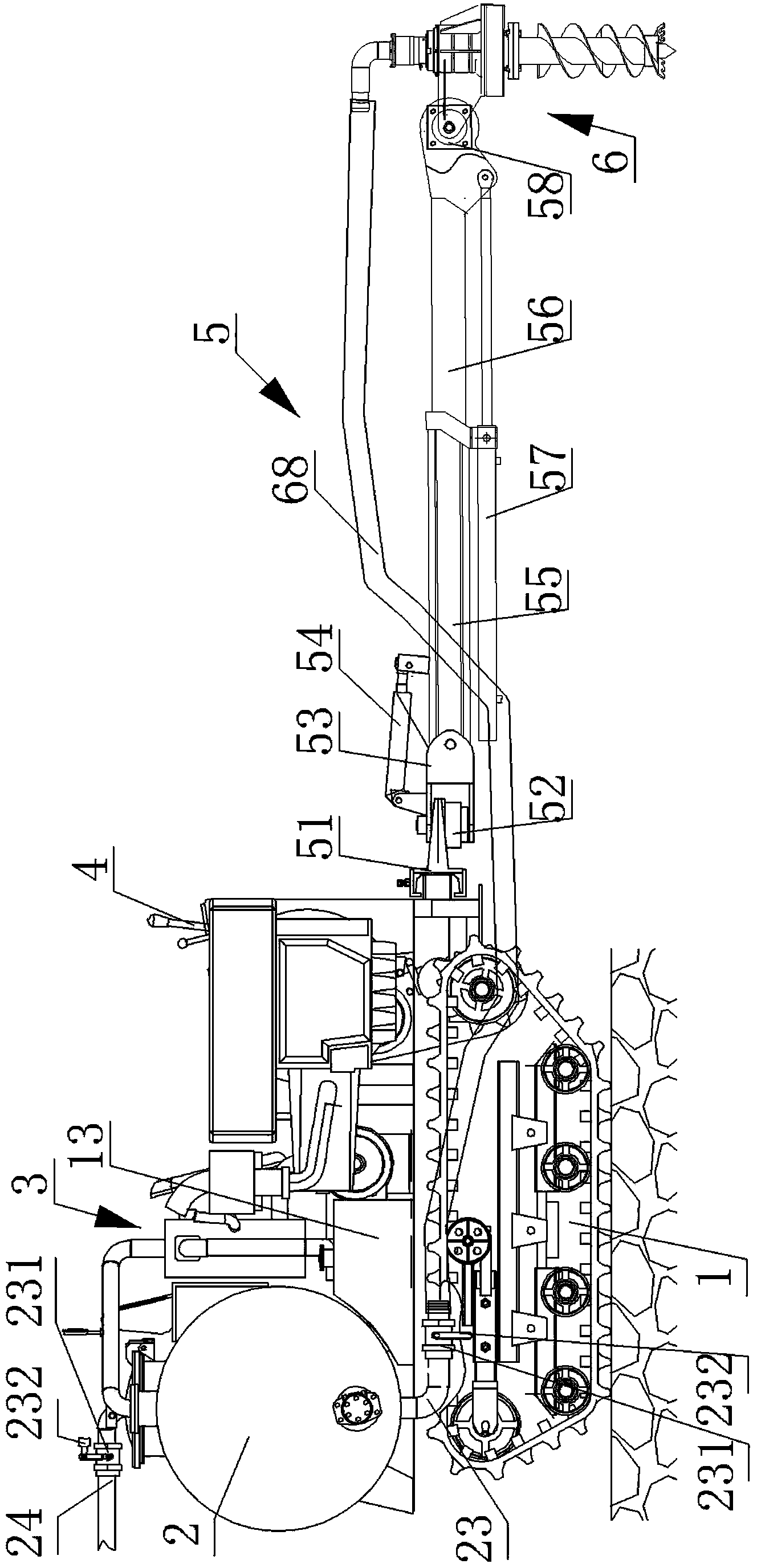

[0029] from Figure 1 to Figure 10 It can be seen that the orchard fertilization vehicle of the present invention includes a chassis 1, a fertilization tank 2, a vacuum system 3, a control system 4, a swing arm system 5 and a fertilizer applicator 6, a fertilizer tank 2, a vacuum system 3, a control system 4 and a rotary The arm system 5 is installed on the chassis 1, and the chassis 1 is equipped with a hydraulic station 11, an engine 12 and a water tank 13, and a feed pipe 24 is arranged above the fertilization tank 2, and a discharge pipe 23 is arranged at the bottom of the fertilization tank 2 , the fertilizer applicator 6 includes a fixed outer casing rod 61, a hollow auger rod 62, a hollow drill bit 63, a discharge inner rod 64, a mechanical seal assembly 65, a hydraulic motor 66 and a cylinder 67, the vacuum system 3 communicates with the fertilization tank 2 and is controlled by the control system 4 Control the opening and driving of the suction or discharge of the fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com