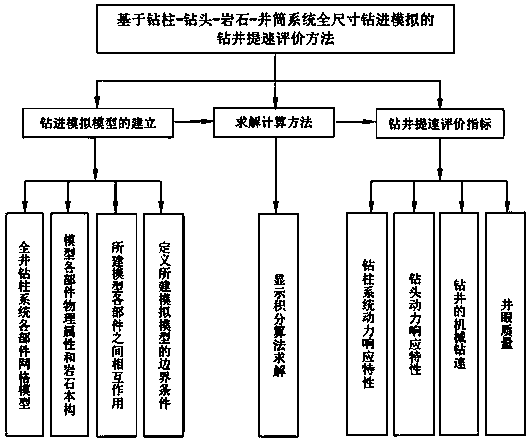

Drilling speed increase evaluation method based on drill stem-drill bit-rock-shaft system full-scale drilling simulation

An evaluation method, full-scale technology, used in wellbore/well components, earthmoving, surveying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained and illustrated below in conjunction with the drawings.

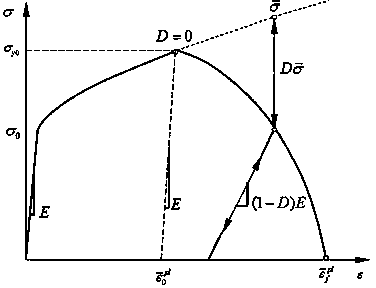

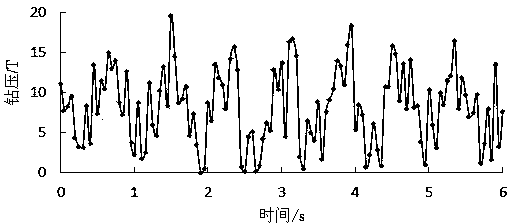

[0027] The invention is based on the finite element model of the full-scale drilling simulation of the drill string-bit-rock-wellbore system, and simulates the real-time drilling process of rock breaking in the drilling engineering through computer simulation. It is mainly composed of three parts. First, a finite element model based on drill string-bit-rock-wellbore system full-scale drilling simulation is established, and then the established finite element model is analyzed and calculated by the display integration algorithm, and finally based on the established evaluation criteria Evaluate the drilling speed increase. It is characterized in that the establishment of the finite element model based on the full-scale drilling simulation of the drill string-bit-rock-wellbore system includes the following steps:

[0028] Step 1. Establish a grid model including the boreho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com