Mechanical underground all-in-one blowout preventer

A blowout preventer and mechanical technology, applied in the direction of wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc., can solve the problems of infeasibility and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

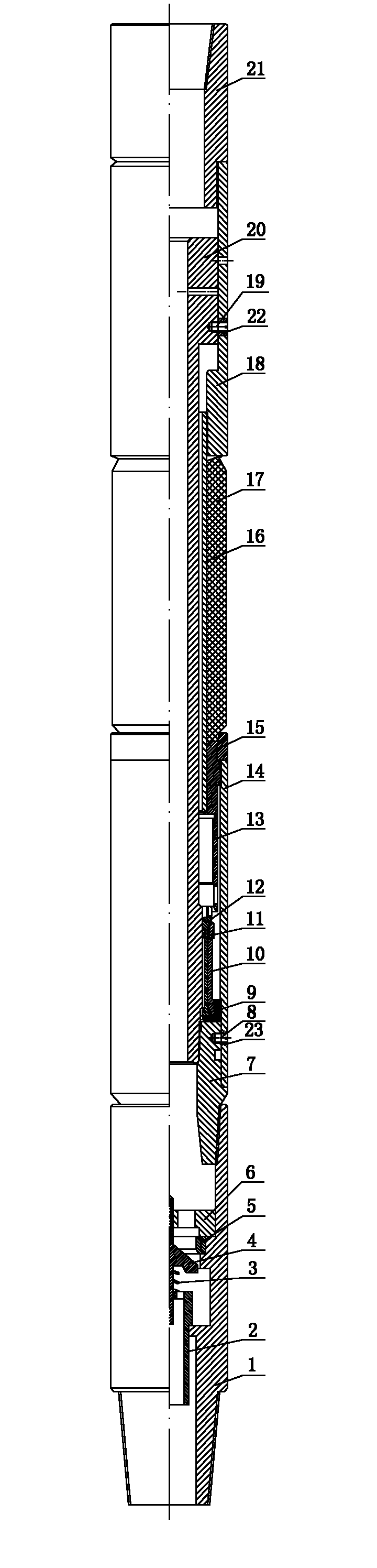

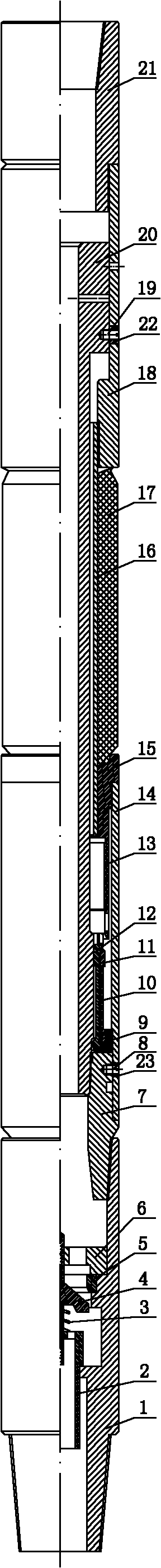

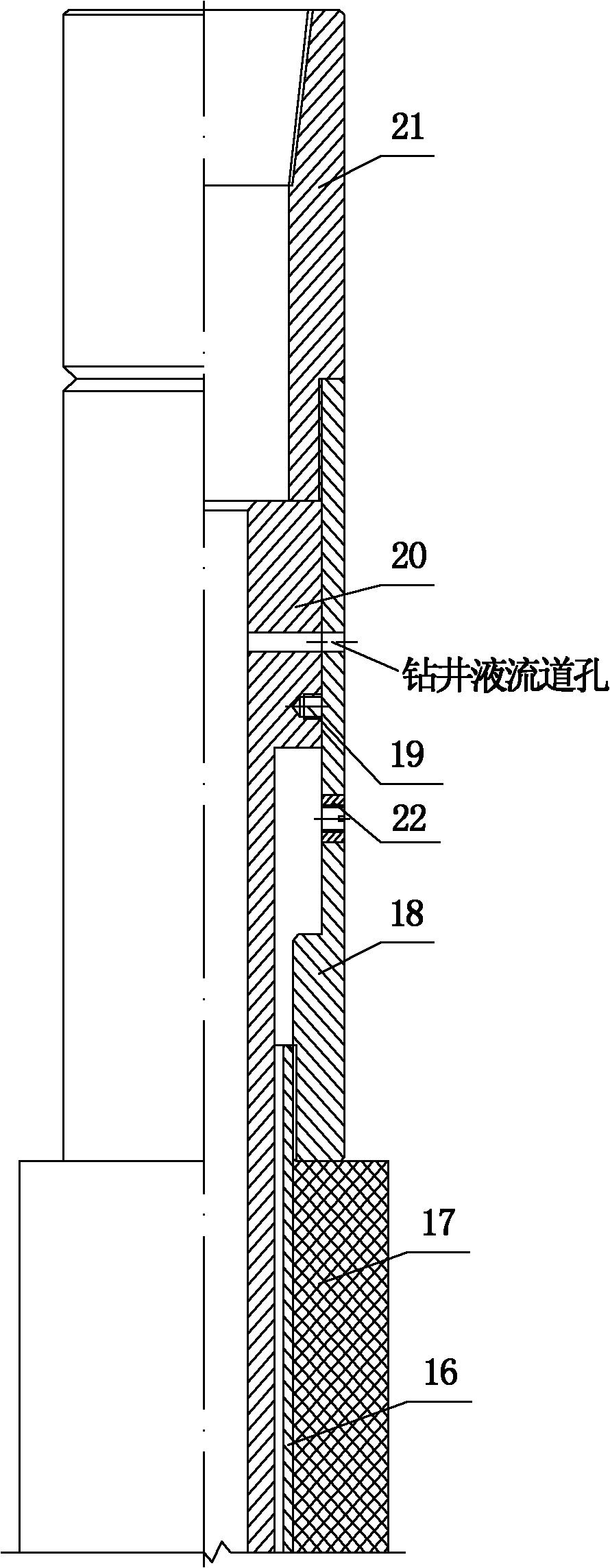

[0013] As shown in Figure 1, the mechanical downhole integrated blowout preventer includes two parts: the arrow-shaped check valve and the outer annular space packer, and the arrow-shaped check valve and the outer annular space packer pass through the thread between the lower joint 7 Make the connection. The arrow check valve includes check valve body 1, joint body 2, valve core spring 3, valve core 4, valve seat 5 and valve seat nut 6, and the joint body 2 is installed on the step inside the check valve body 1 , the upper part of which is provided with a number of flow channel openings, and a number of evenly distributed flow channel openings are opened in the circumferential direction of the thickened step. The joint body 2 supports the spool, the spring 3 compresses the spool 4, and is close to the valve seat 5. The valve seat 5 is installed on the step in the check valve body 1, and the valve seat is pressed by the valve seat nut 6. The valve seat nut is threaded and Chec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com