Mine drilling machine

A technology for drilling rigs and mines, which is applied in the direction of rotary drilling rigs, earthwork drilling, drilling equipment, etc. It can solve the problems of inaccurate measurement of drilling depth and achieve the effect of preventing insufficient drilling depth, simple structure and ensuring effective depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

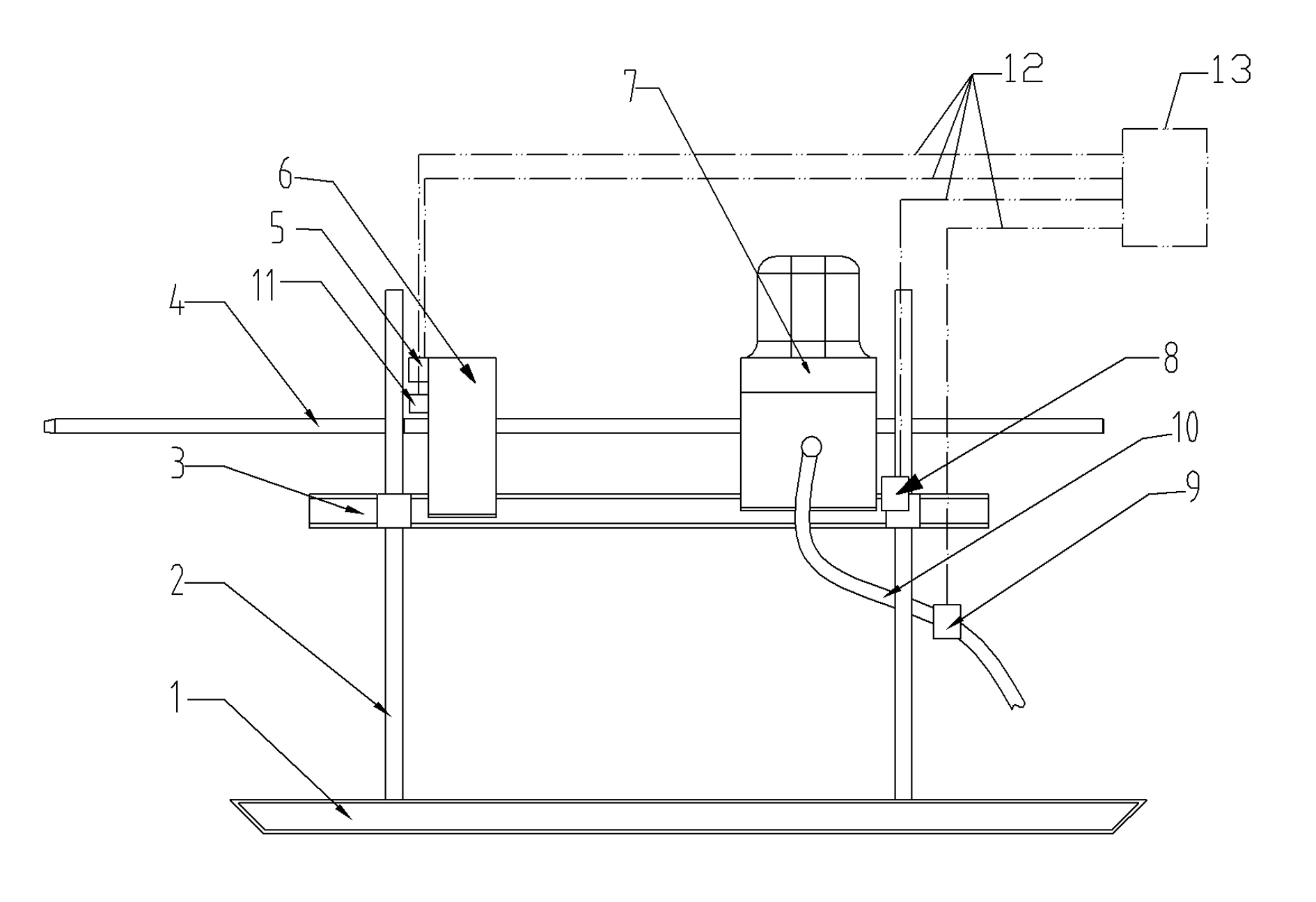

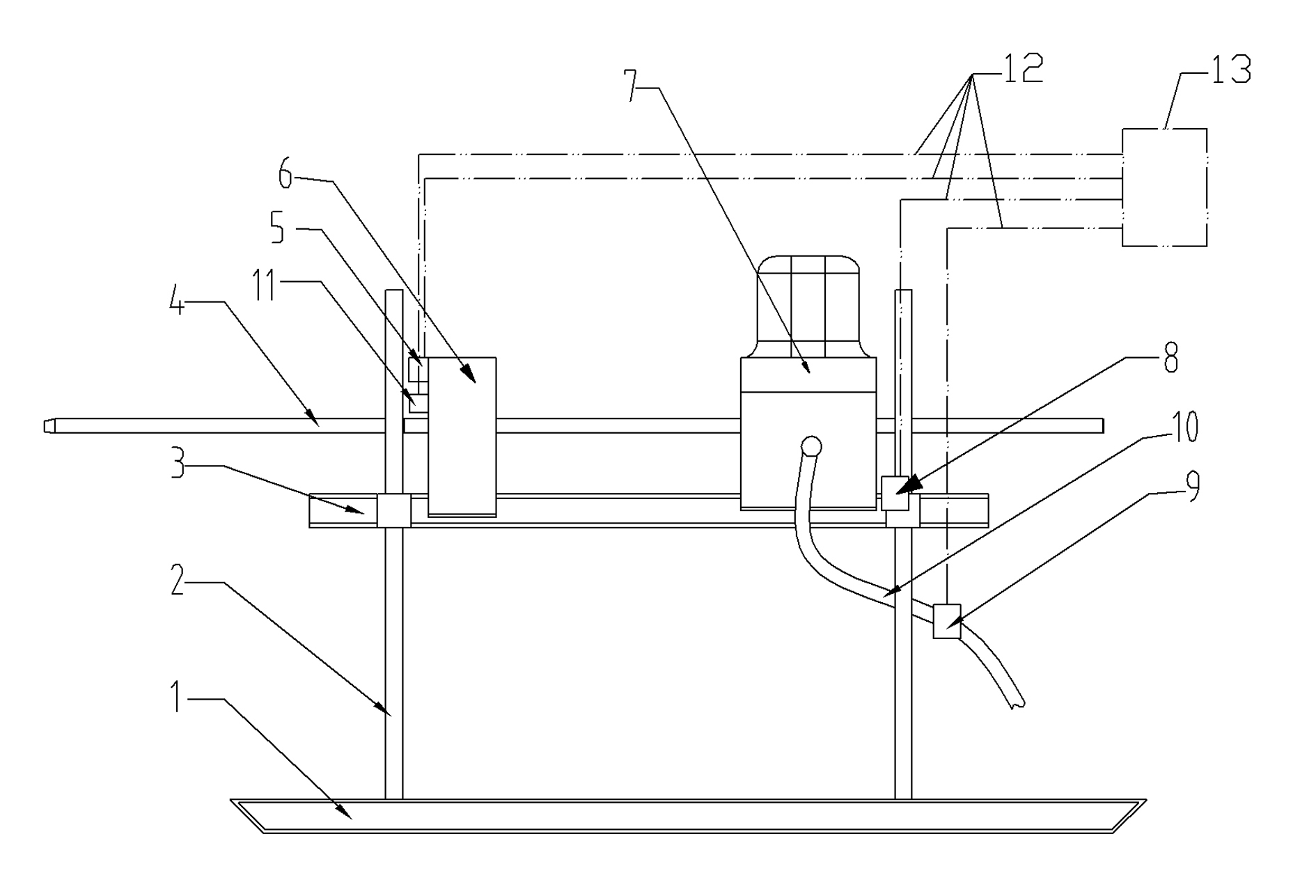

[0013] Such as figure 1 As shown, the mine drilling machine includes a base 1, a support 2 is fixed on the base 1, a slide rail 3 is arranged on the support 2, and a power drive device for driving the drill rod 4 is slidably mounted on the slide rail 3 of the support 2, The power drive device reciprocates on the support. In this embodiment, the power drive device is a gyrator 7. A support device 6 for coordinating with the gyrator 7 to support the drill pipe 4 is fixed at the front end of the support 2. On the support device 6 A support hole for slidingly fitting with the drill rod 4 is provided, a displacement sensor 5 for detecting the total displacement of the drill rod 4 relative to the support 2 is provided on the support device 6, and a displacement sensor 5 for detecting the total displacement of the drill rod 4 relative to the support 2 is provided on the support device 6. A counter for counting the number of standard drill pipes 4 in the hole, what the counter in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com