Hydraulic expansion type tail pipe hanger

A liner hanger and expansion technology, which is applied in wellbore/well components, sealing/packing, earth-moving drilling, etc., can solve the leakage of casing annulus cement ring seal, which is not conducive to subsequent operations, and the effect of seat sealing It can achieve the effect of good sealing quality, simple structure and large inner diameter of the pipe string.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

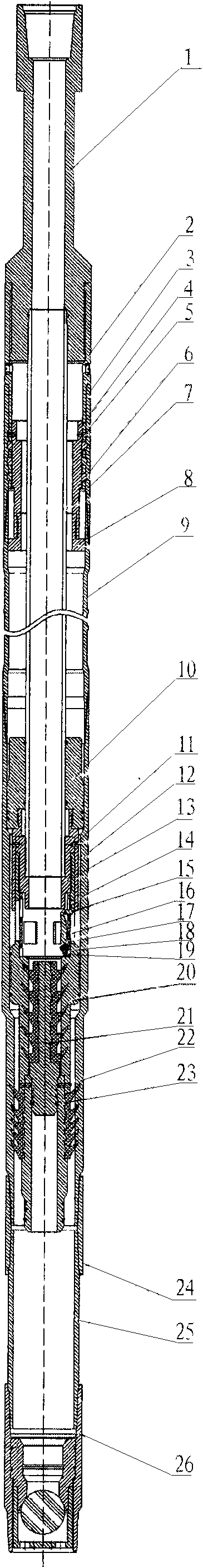

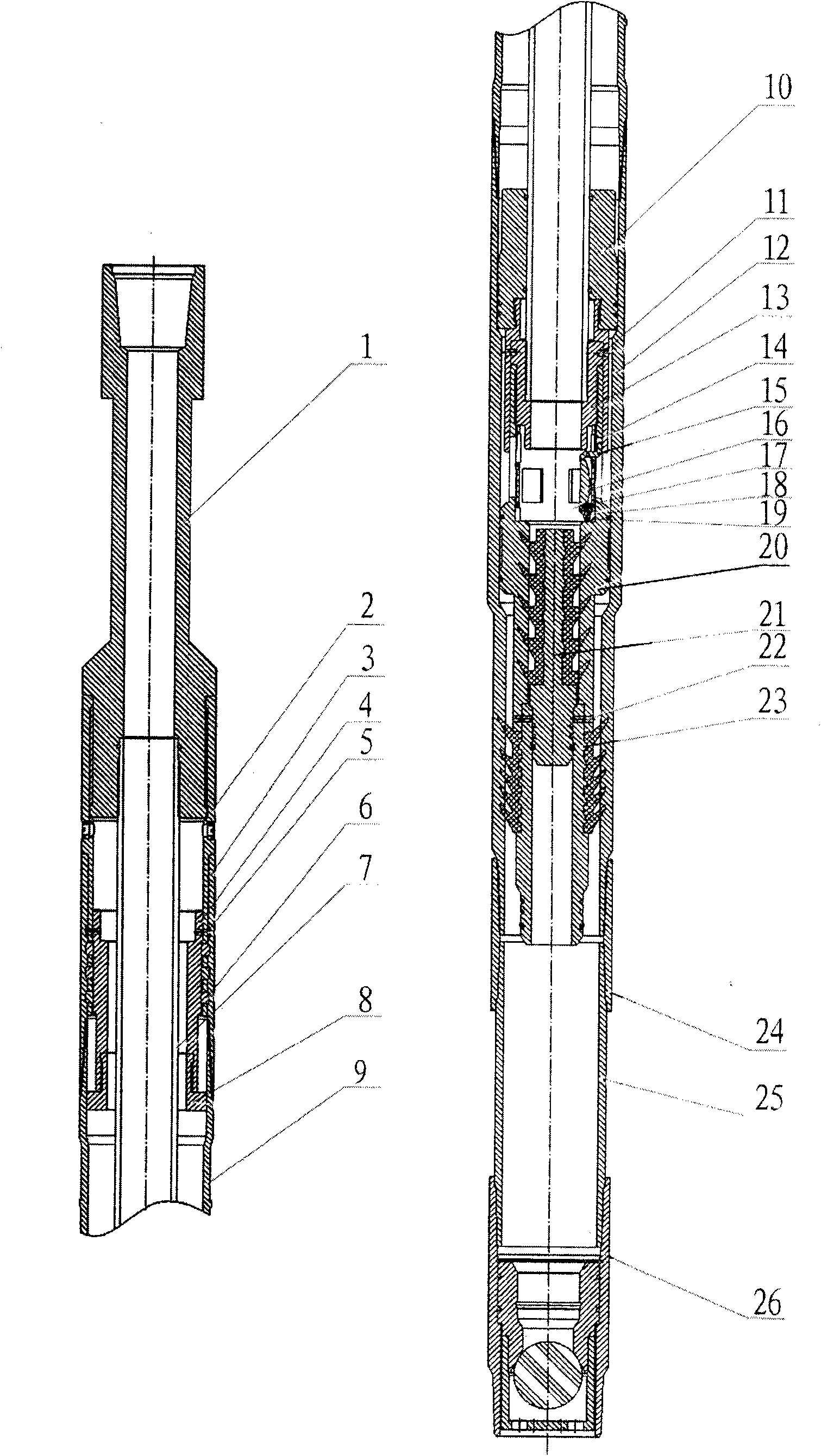

[0016] Such as figure 1 or figure 2 As shown, the drill pipe thread at the upper end of the drop joint 1 is screwed with the drill string, the inner thread at the lower end of the drop joint 1 is screwed with the central pipe 7, and the outer side of the central pipe 7 is sleeved with an expansion cone 10, which passes through the shear nails. B 11 is connected with the float valve sleeve 17, the expansion cone 10 slides freely on the center pipe 7, and the expansion cone 10, the expansion pipe 9 and the center pipe 7 realize a dynamic sealing fit through several sealing rubber rings. The screw thread of central tube 7 lower ends is screwed with float valve sleeve 17, and hinge seat 18, hinge 19, shift fork 15, valve cover 16 and spring are installed on float valve sleeve 17. The floating valve sleeve 17 is cylindrical, and its upper and lower ends are provided with pin holes, the pin holes at the upper end are connected with the shift fork 15 with pins, and the pin holes at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com