Rotary pushing type guiding drilling tool

A technology for directional drilling and tools, applied in directional drilling and other directions, can solve the problems of high requirements for supporting tools, processes and equipment, high use and maintenance costs, and difficulty in general promotion, achieving broad field application prospects, reliable work, and low cost The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

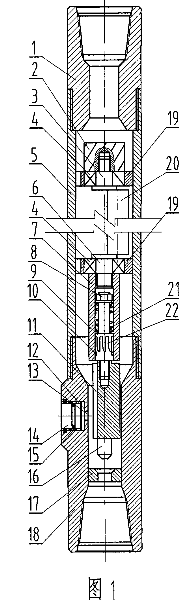

[0013] The present invention will now be further described with reference to the accompanying drawings.

[0014] When the present invention is used for steerable drilling construction, the upper and lower ends of the stabilizing block [20] are respectively connected with the upper mandrel [3] and the lower mandrel [6], and the axis of the stabilizing block [20] is connected with the upper mandrel [3] The axis of the lower mandrel [6] does not coincide, put the bearing [4] into the bearing fixing ring [19], and then put the bearing [4] into the upper mandrel [3] and the lower mandrel [6], the rectifier head [2] ] is connected to the upper end of the upper mandrel [3], the middle outer surface of the guide shaft [9] is machined with a guide groove [22], the guide shaft [9] is loaded into the guide cylinder [7], and the dial [10] is fixed on the The inner wall of the lower end of the guide cylinder [7] extends into the guide groove [22] on the guide shaft [9], the spring [21] is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com