Downhole vibration monitoring method

A vibration monitoring and stick-slip vibration technology, applied in the automatic control system of drilling, drilling equipment, earth-moving drilling, etc., can solve the problems of insufficient wellbore purification, low rock breaking efficiency, poor mud performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

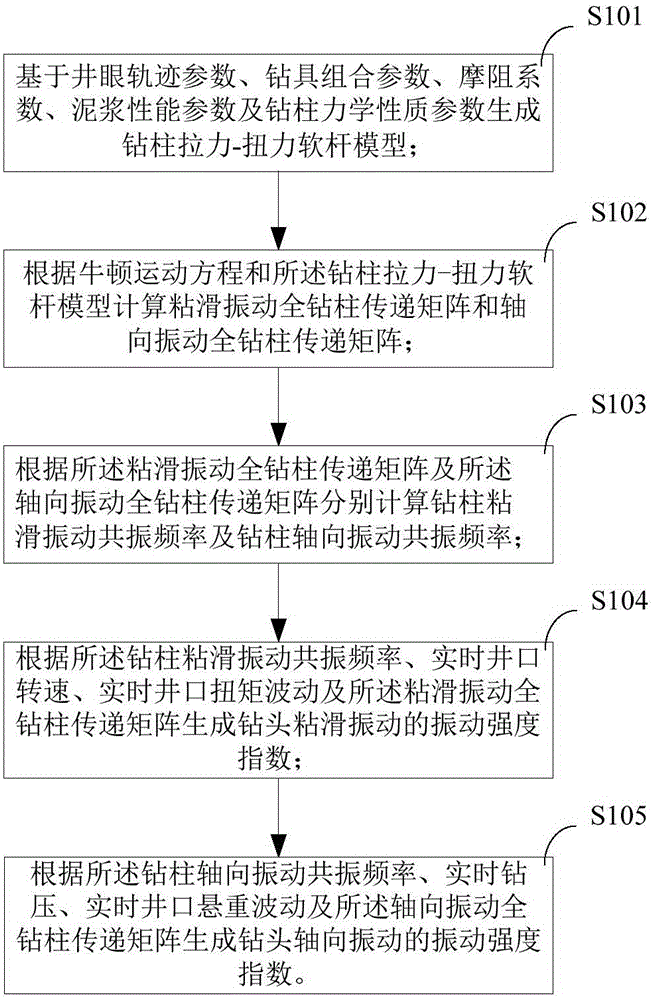

[0112] figure 1 is a schematic flow chart of the vibration monitoring method of the embodiment of the present invention. like figure 1 As shown, the vibration monitoring method includes steps:

[0113] S101: Generate a drill string tension-torque soft rod model based on wellbore trajectory parameters, drilling tool assembly parameters, friction coefficient, mud performance parameters and drill string mechanical property parameters;

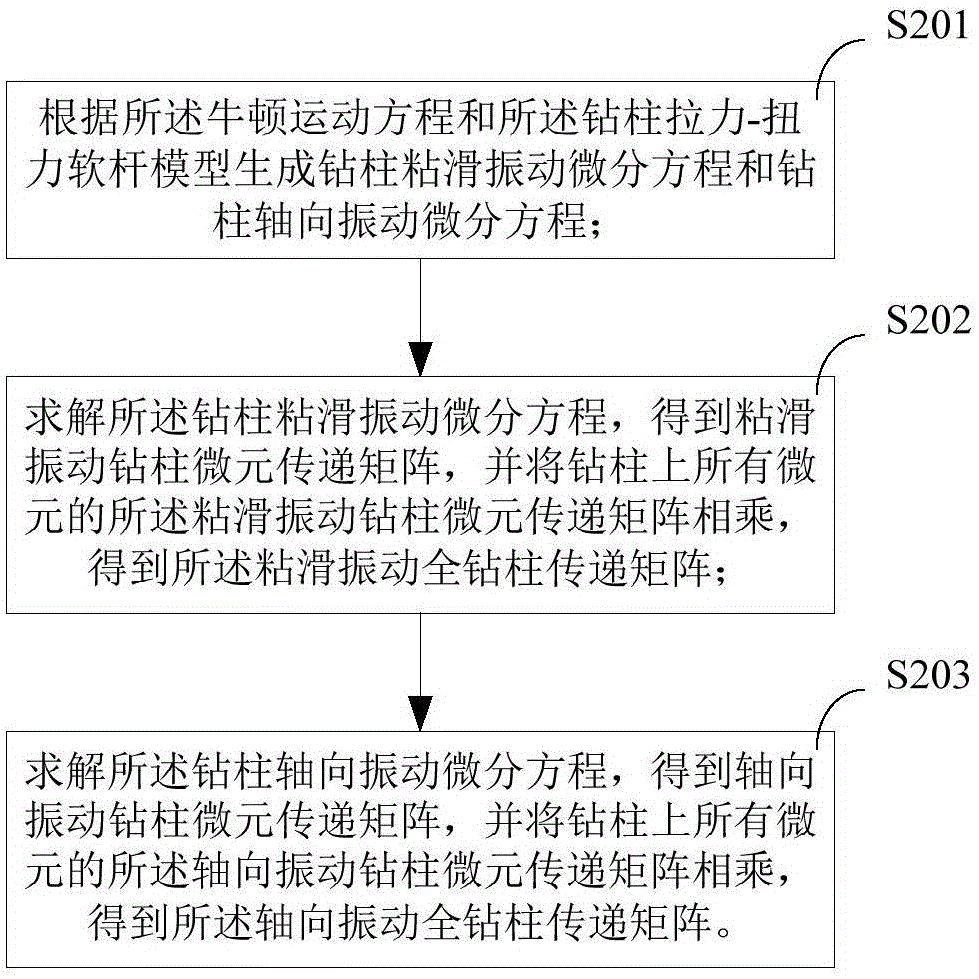

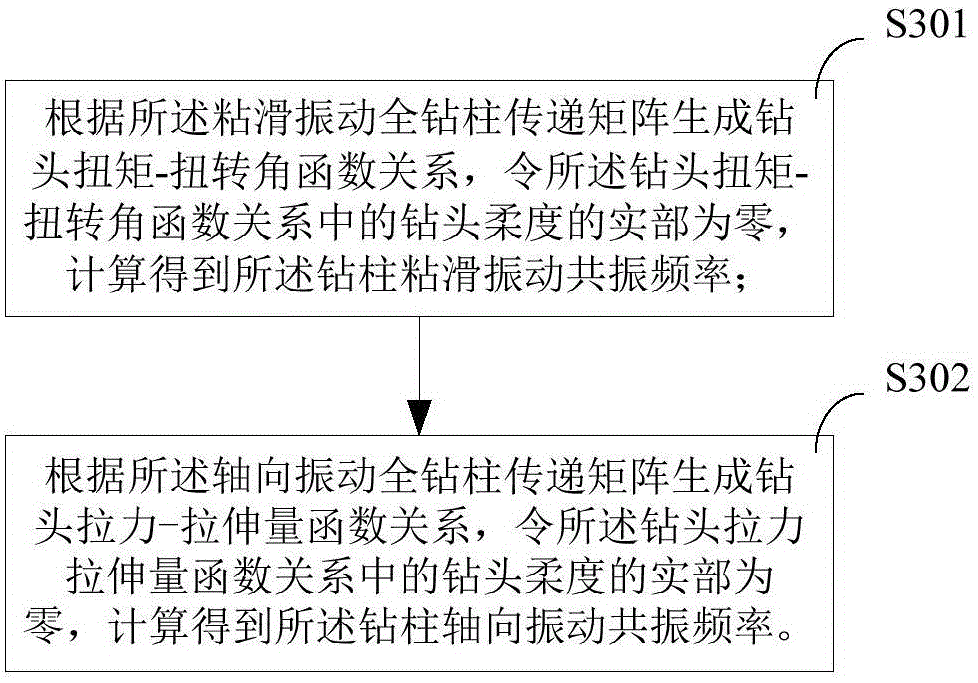

[0114] S102: Calculate the stick-slip vibration full drill string transfer matrix and the axial vibration full drill string transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com