Solar flexible transmission day-by-day system

A flexible transmission and solar energy technology, applied in the direction of transmission, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of large moment of inertia and rotational load, difficult installation of tracking system, poor system stability, etc., to reduce the moment of inertia and lighten the rotation effect of load, increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

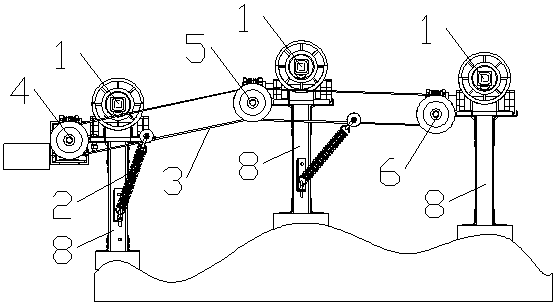

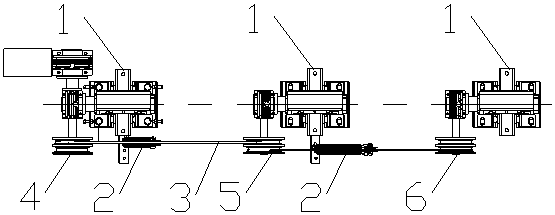

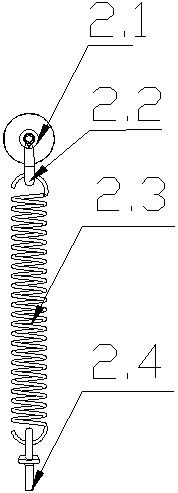

[0041] see Figure 1-5 , The present invention relates to a solar flexible transmission daily system, which includes an eccentric structure, a tensioning device, a flexible wire rope transmission device and a support column 8.

[0042] The eccentric structure includes an eccentric bent shaft 1. The eccentric bent shaft 1 includes a middle section 1.1, an installation section 1.2 and a fixed section 1.3. The installation section 1.2 is provided with a battery board 9, and the center of gravity of the installation section 1.2 and the battery board 9 is the same as that of the middle section 1.1. The center of gravity is flush, the installation section 1.2 is located on both sides of the middle section 1.1, the installation section 1.2 and the middle section 1.1 are transitionally connected by a bent plate, the fixed section 1.2 is respectively located on the outside of the two installation sections 1.2, and the fixed section 1.2 and the installation section 1.2 are transitionally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com