Construction method for shield holing under complicated working conditions

A technology with complex working conditions and construction methods, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as complex construction conditions and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] The shield tunneling construction method under complex working conditions of the present invention:

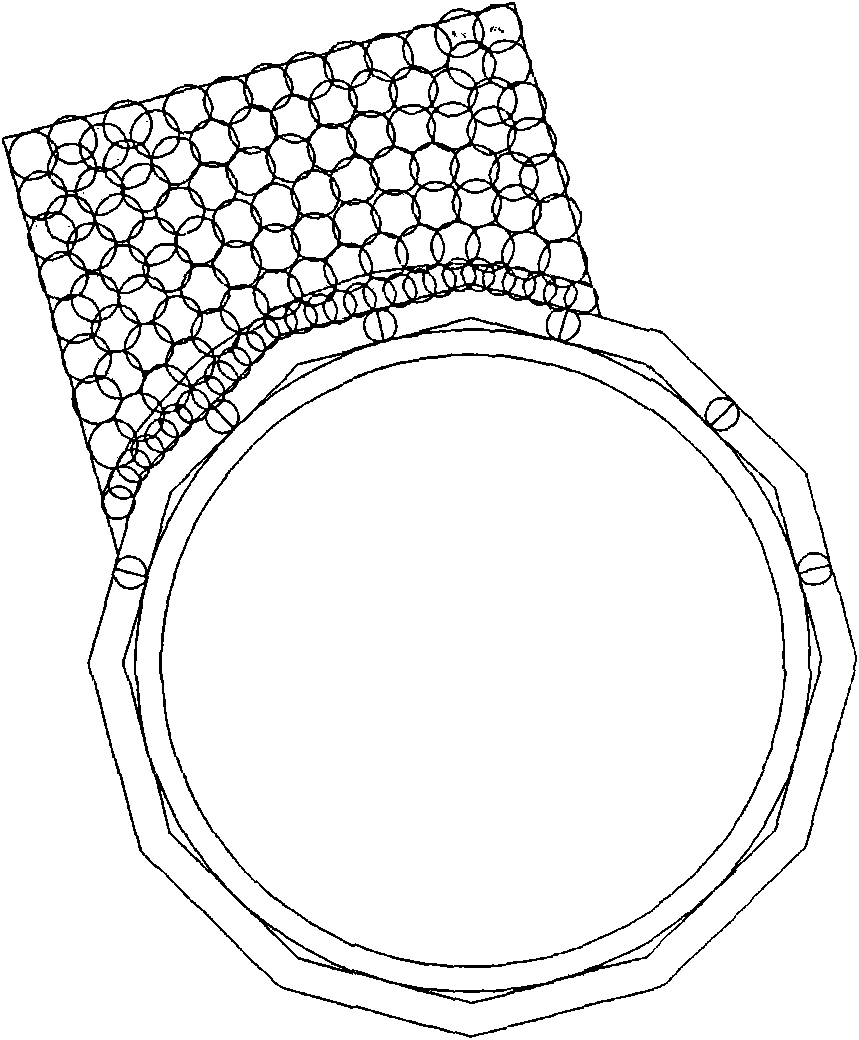

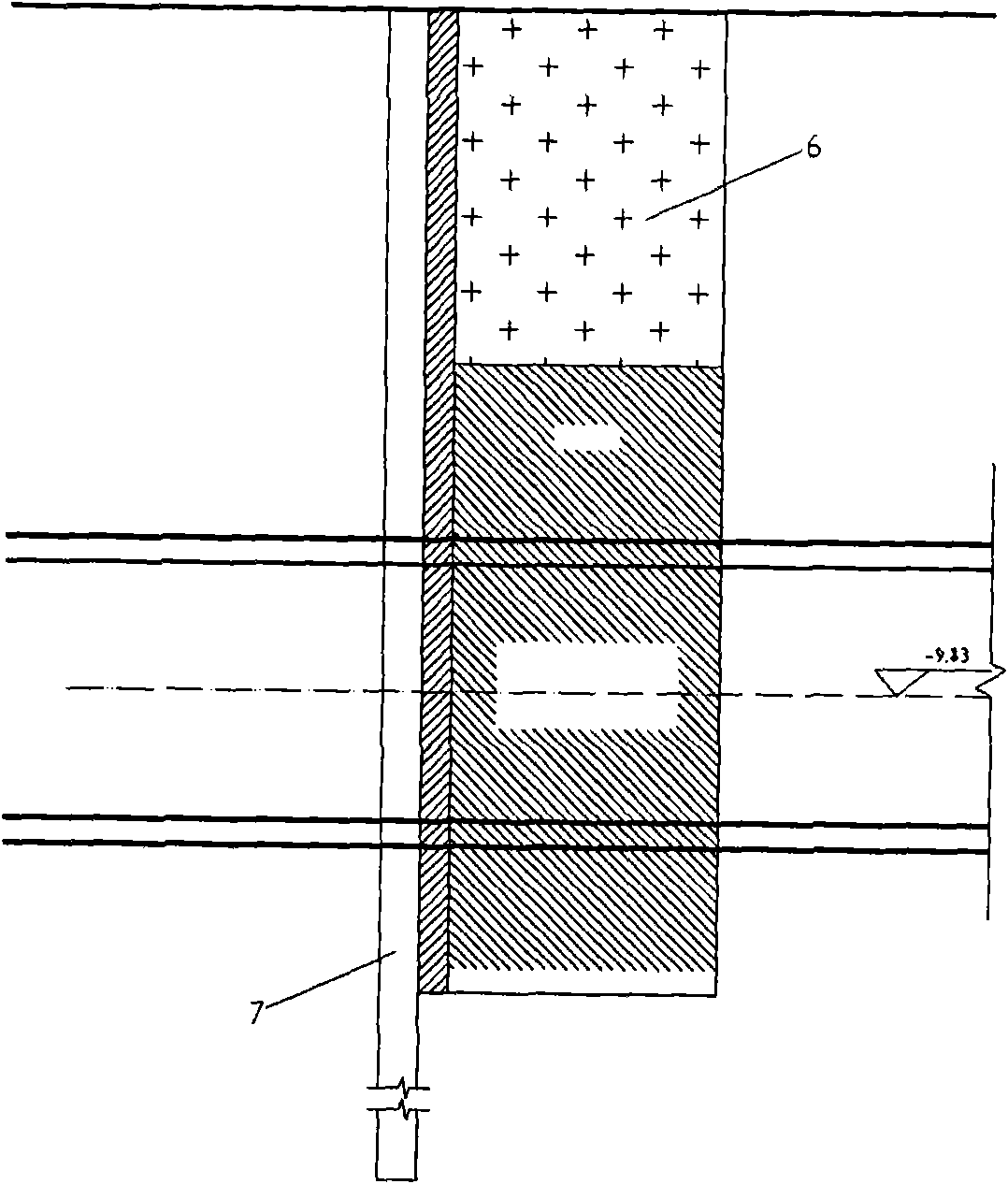

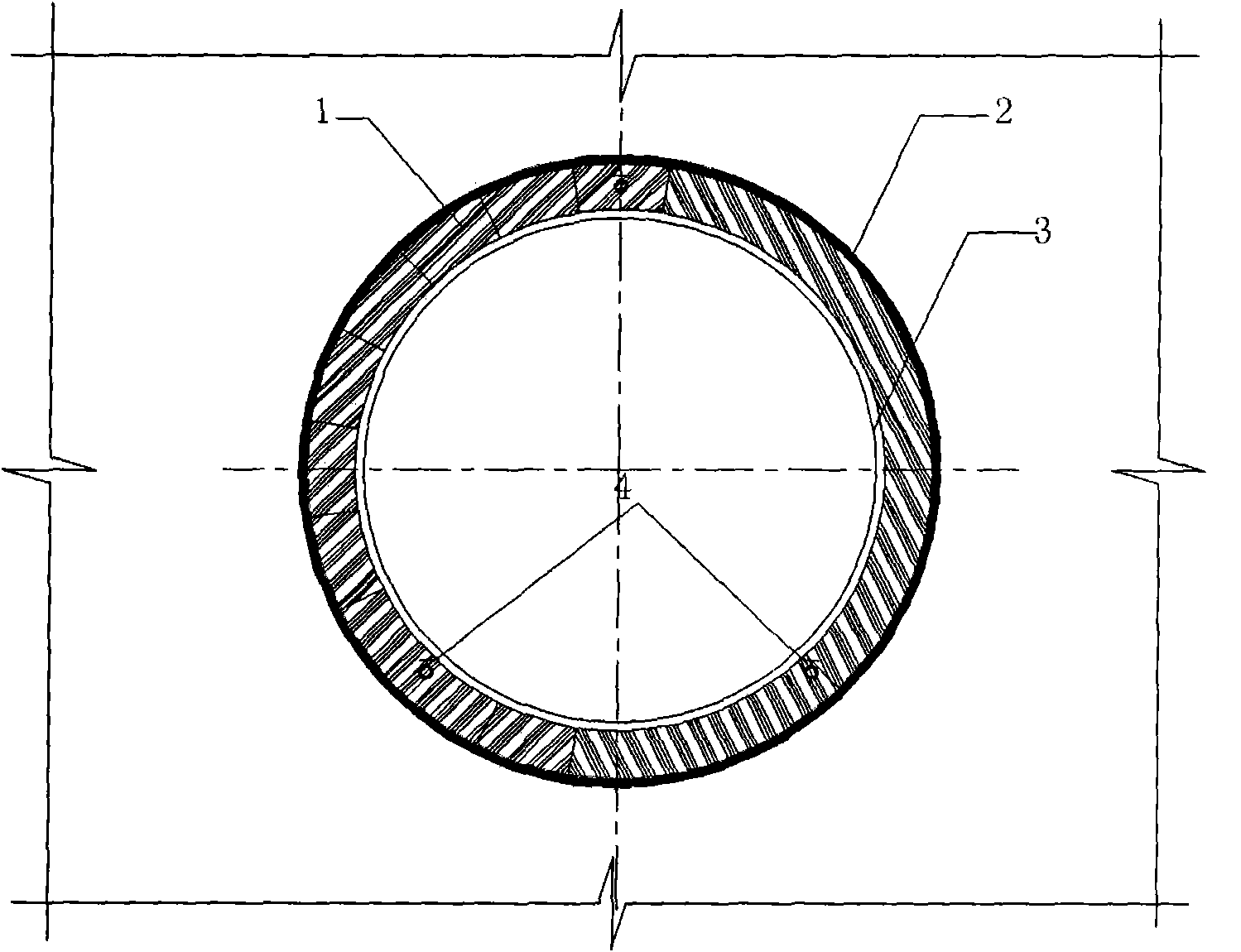

[0032] 1. In order to ensure the smooth entry of the shield tunnel and ensure the safety of surrounding buildings and underground pipelines, soil reinforcement is carried out at the entrance of the tunnel. Such as figure 1 , as shown in 2, triple pipe high-pressure rotary grouting piles are used for soil reinforcement at the entrance of the shield tunnel (to reduce the impact on the surrounding environment), and the designed pile diameter of a row of piles near the ground wall 7 in the shield tunnel reinforcement area is 800mm , the remaining parts are designed with a pile diameter of 1200mm, arranged in a quincunx shape, and adjacent piles are overlapped by 300mm. The reinforcement of the hole entrance will be carried out in combination with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com