Underground grouting and water-plugging process

A grouting and process technology, applied in wellbore lining, underground chamber, shaft equipment, etc., can solve the problems affecting grouting quality, small amount of grouting, large amount of grouting, etc., so as to ensure the quality of grouting and reduce the amount of grouting. , the effect of controlling the diffusion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

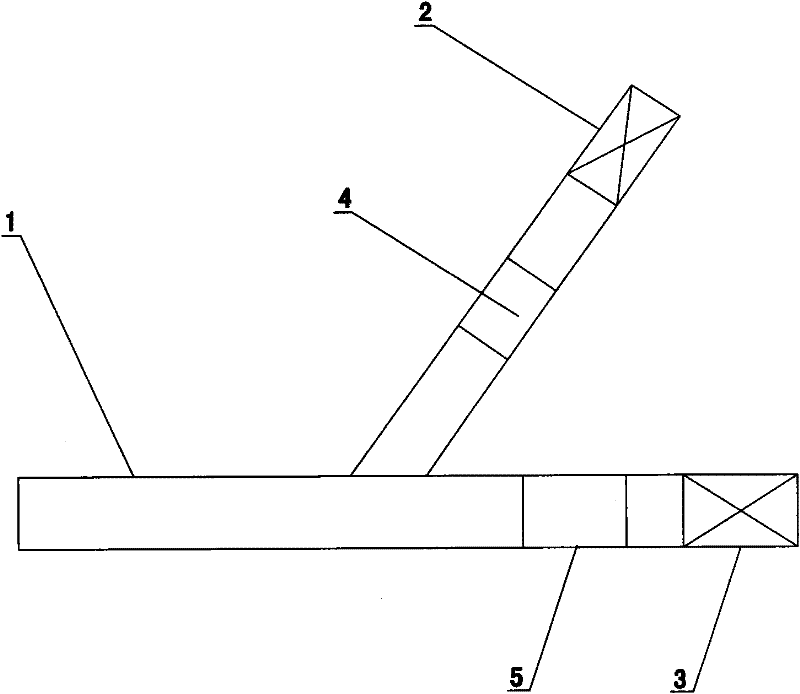

[0030] The present invention will be further described below in conjunction with the accompanying drawings of the description.

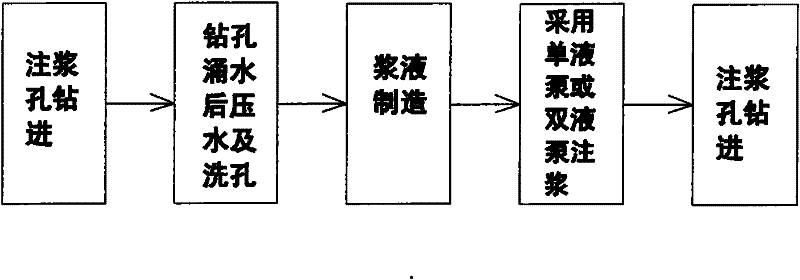

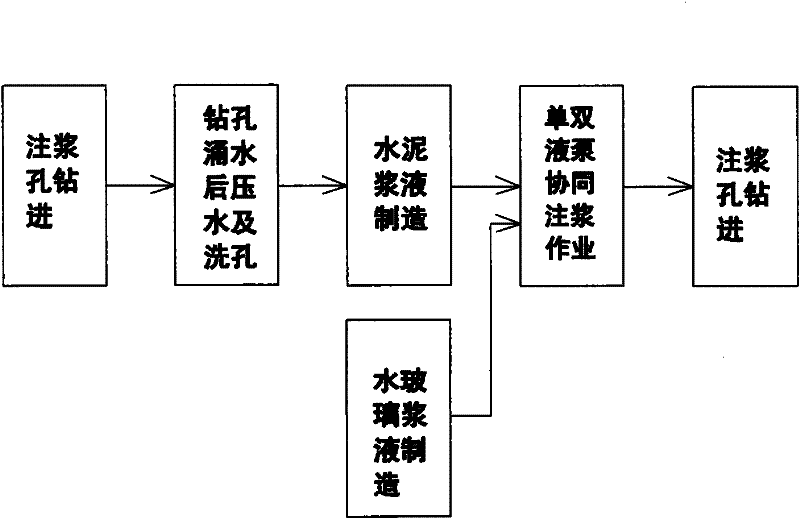

[0031] see figure 2 with image 3 , the downhole grouting water plugging technique of the present invention, comprises the following steps:

[0032] The first step: grouting hole drilling

[0033] When it is predicted that there will be water in front of the construction roadway, the drilling rig is used to drill or drill the grouting hole, and at the same time, the orifice pipe for grouting is installed to prepare for the grouting and water blocking operation after water gushing. After the borehole is drilled into the water guide or water storage structure, water gushing occurs. When the water gushing volume is greater than a certain value (generally 10m 3 / h), grouting and water blocking operations are required.

[0034] The second step: water pressure and hole washing after drilling water gushing.

[0035] After water gushing occurs in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com