Tunnel advanced support air circulated drilling construction method and drilling tool

A technology of advanced support and construction methods, which is applied in the direction of tunnels, drilling tools, tunnel linings, etc., to achieve the effect of ensuring construction safety and construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

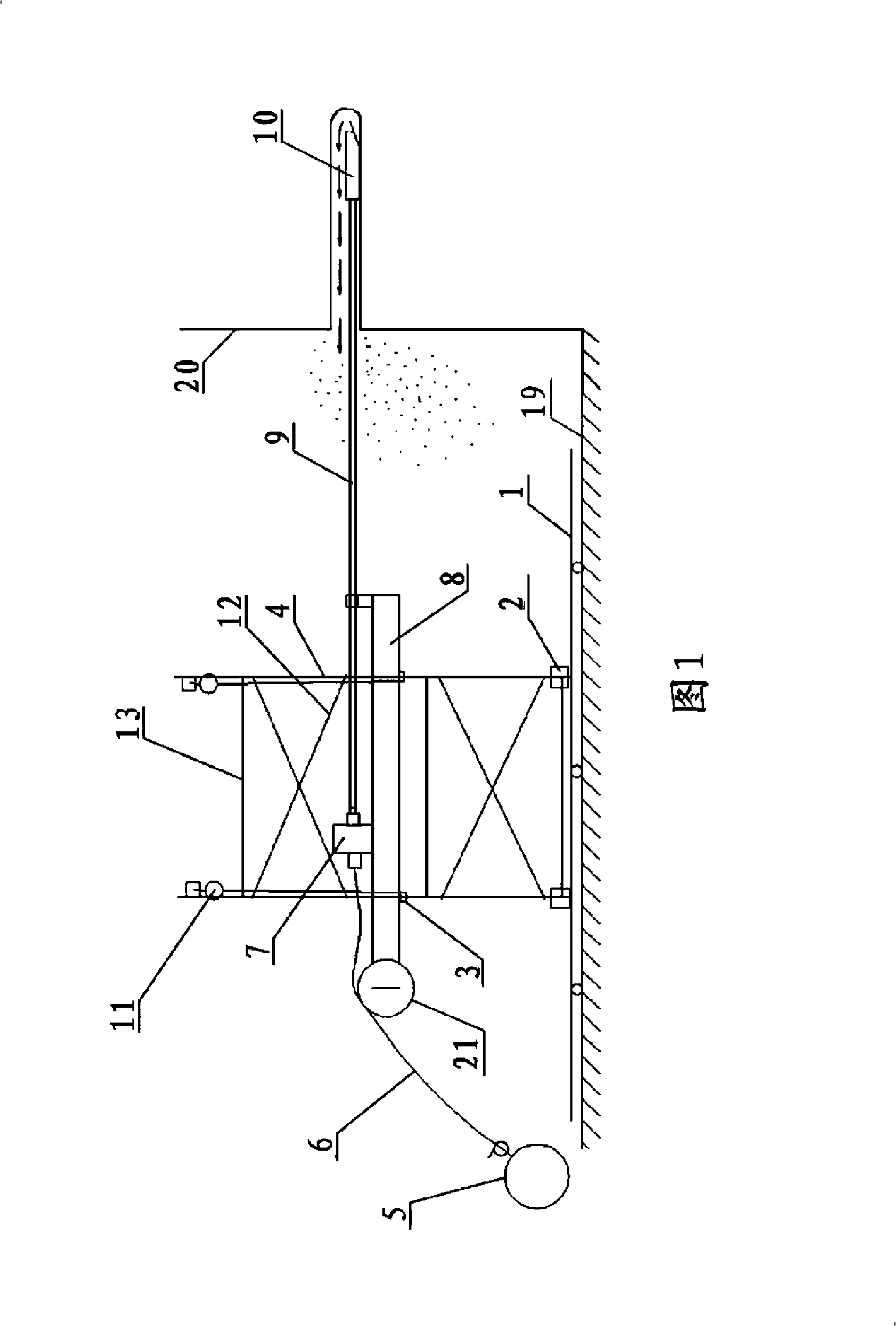

[0032] Embodiment 1 Referring to Fig. 1, the construction steps of this tunnel advance support wind circulation drilling construction method are as follows:

[0033] Step 1, drilling tool installation, leveling the working surface 19 in front of the support surface 20, laying the track 1 parallel to the support surface 20 and perpendicular to the tunnel axis, erecting the frame on the track 1, and using inclined rails on the sides and up and down of the frame. The ties are tight, and the four corners of the base are reinforced with high-strength bolts on steel backing plates. The drilling rig is placed on two beams for lifting, and hand chain hoists are hung on the top of the four columns to lift the beam of the drilling rig. The beams and columns are clamped. The tiles are connected, and the frame is moved by a traveling cylinder. The drill pipe 9 used as the pipe shed steel pipe is horizontally supported on the drill carriage 8 on the frame, the front end of the drill pipe i...

Embodiment 2

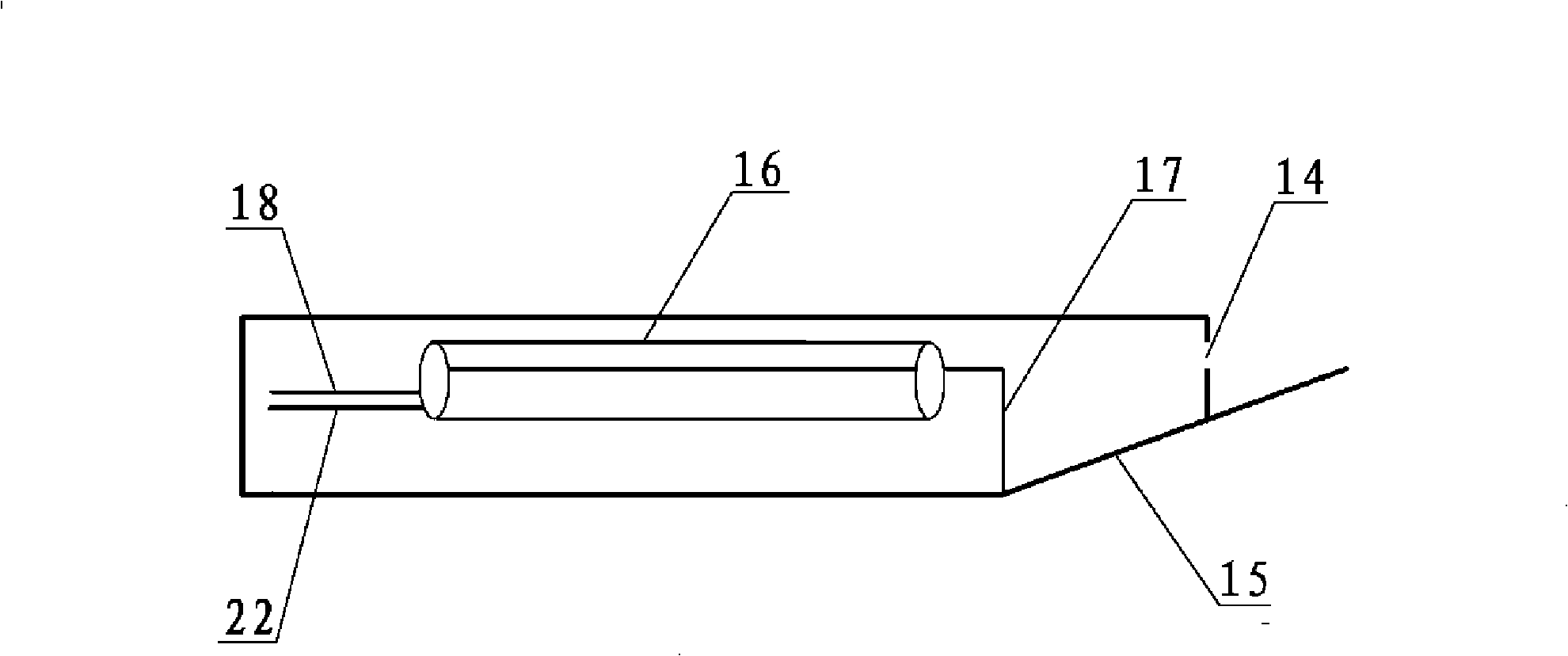

[0038] Embodiment two see figure 2 As shown, the difference between the construction method of this tunnel advance support wind circulation drilling construction method and the first embodiment is that the drill bit is also connected with the guide drilling device, and the construction steps are as follows:

[0039] Step 1, drilling tool installation, leveling the working surface 19 in front of the support surface 20, laying the track 1 parallel to the support surface 20 and perpendicular to the tunnel axis, erecting a frame on the track 1, which will be used as the steel pipe for the pipe shed The drill pipe 9 is horizontally supported on the drill carriage 8 on the frame. The front end of the drill pipe is connected to the drill bit 10 with an air outlet on the head. The probe is fixed on the inner wall of the drill bit by the support, and the guide probe 16 is connected with the external display screen and the guide drilling device by the signal line. The guide probe must ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com