Contraction-free cement grout material

A cement grouting and non-shrinkage technology, which is applied in the field of cement grouting materials, can solve the problems of unspecified grouting materials, and achieve the effects of low cost, good self-flowing property and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: according to weight percentage, the formula of this grouting material is:

[0034] High alumina cement: 20.0%,

[0035] 52.5R cement: 22.0%,

[0036] Anhydrite: 5.0%,

[0037] Expanding agent: 5.45%,

[0038] Water reducer: 1.5%,

[0039] Coagulant: 0.05%,

[0040] Shrinkage reducer: 0.99%,

[0041] Thickener: 0.01%,

[0042] Aggregate: 45.0%.

[0043] The product of this embodiment is mainly used in projects with high early strength requirements, such as replacement or emergency repair of heavy machinery and equipment foundations, emergency repair grouting of road bridge joints, rapid grouting of high-speed railway bridge bearings, and the strength can exceed 20MPa within 6 hours. Simple, safe and reliable.

Embodiment 2

[0044] Embodiment 2: according to weight percentage, the formula of this grouting material is:

[0045] 42.5 Cement: 45.0%,

[0046] Silica fume: 3.0%,

[0047] Expanding agent: 5.0%,

[0048] Water reducer: 1.0%,

[0049] Shrinkage reducer: 0.99%,

[0050] Thickener: 0.01%,

[0051] Aggregate: 45.0%.

[0052] The product of this embodiment is mainly used for anchoring of anchor bolts, cutting and embedding steel bars, secondary grouting of equipment foundations with a grouting layer thickness of 30mm<δ<200mm, or reinforcement of beams, slabs, columns, foundations and floors of buildings ( Repair thickness ≥ 40mm).

Embodiment 3

[0053] Embodiment 3: according to weight percentage, the formula of this grouting material is:

[0054] 52.5R cement: 5.0%,

[0055] 42.5 Cement: 25.0%,

[0056] Silica fume: 3.0%,

[0057] Expanding agent: 5.0%,

[0058] Water reducer: 1.0%,

[0059] Aggregate: 61.0%.

[0060] The product of this embodiment is mainly used for the grouting needs of high-precision and complex structural equipment, and the grouting parts do not leave dead angles, and have good stability.

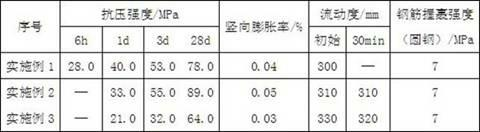

[0061] Table 1 The performance of the grouting material obtained in the examples

[0062]

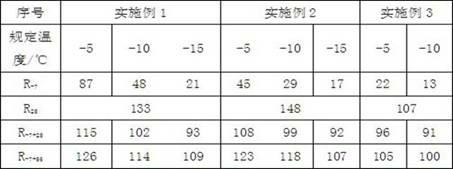

[0063] Table 2 The compressive strength ratio of the grouting materials obtained in the examples at negative temperature

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com