Mining-coal bed nearly horizontal gas extraction borehole sealing method

A gas drainage and horizontal technology, which is applied in the directions of sealing/isolation, earth-moving drilling, wellbore/well components, etc., can solve the problems of not reaching the sealing state, insufficient sealing length, toxicity of sealing materials, etc., to increase the flow rate. The effect of reducing resistance, air leakage, and maximizing crack sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

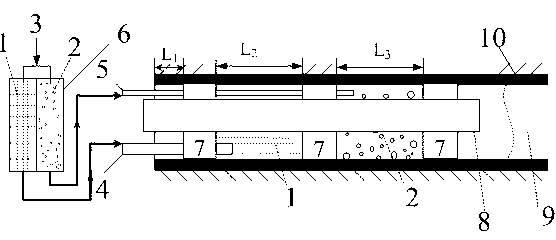

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0015] The coal seam near-horizontal gas drainage borehole sealing method of the present invention comprises: static sealing and dynamic sealing two parts, for a gas drainage borehole, carry out static sealing first, it comprises two grouting processes: the first time The grouting uses expansive cement slurry to seal the position outside the borehole fracture zone; the second grouting uses mud to seal the position inside the fissure zone; after a period of gas, dynamic sealing is performed, and the expansion cement slurry and mud are continuously flowed by the downhole compressed air Inject into the borehole so that the expansive cement slurry and mud are always filled with the borehole and its surrounding cracks to achieve dynamic sealing. The specific steps are as follows:

[0016] a. After the gas drainage borehole (9) is formed, a long grouting pipe (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com