Reamer bit for building long-screw pile machine

A technology of long screw pile driver and reaming bit, which is applied to drill bits, drilling equipment, earth-moving drilling, etc. The effect of improving pile quality and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

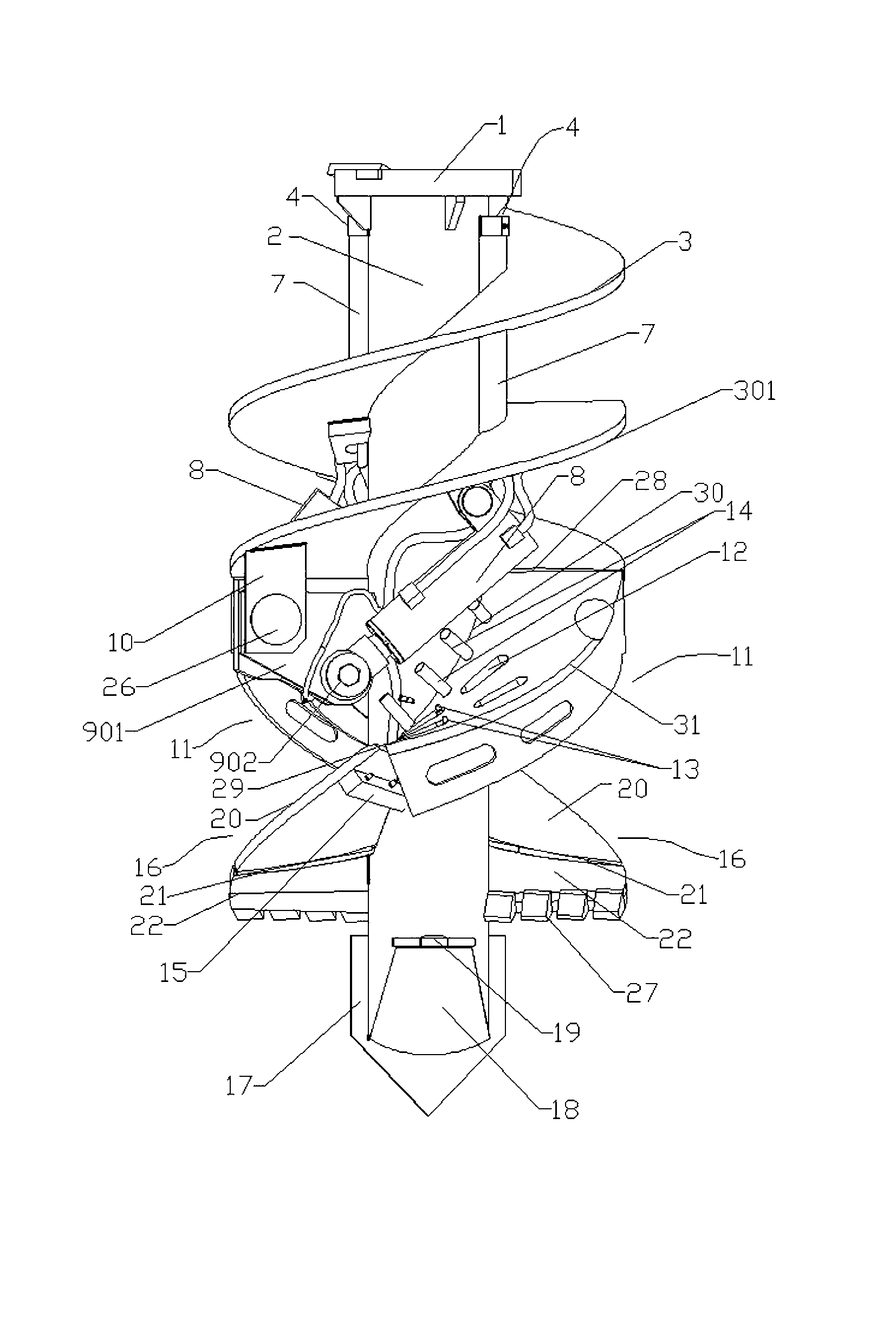

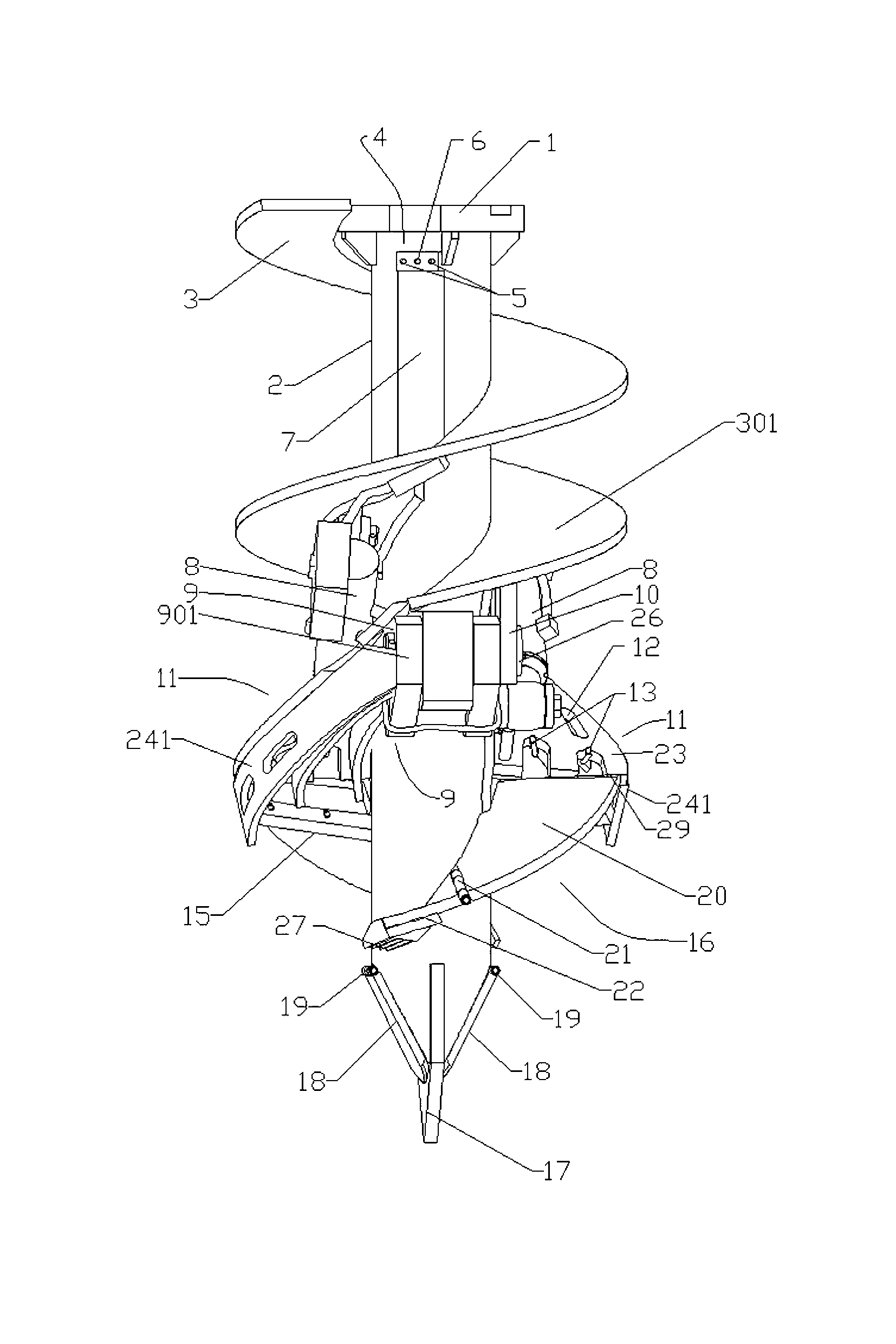

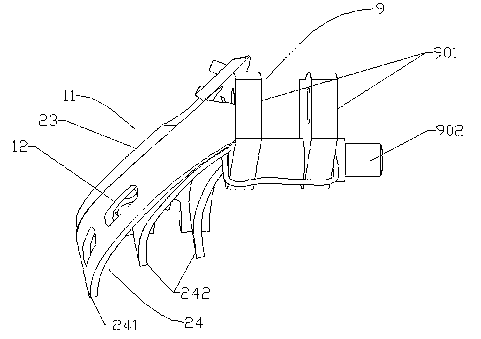

[0053] Examples such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the reaming drill bit for a long screw pile machine for construction includes a hollow drill rod 2, the upper end of the drill rod 2 is fixedly connected with a flange 1, and the lower end of the drill rod 2 is fixedly connected with a drill tip 17, so The outer wall of the drill rod 2 is fixedly connected with a helical blade.

[0054] Described helical blade comprises main helical blade 3, auxiliary helical blade 301, and described main helical blade 3 extends to the middle part of drilling rod 2 along the outer wall of drilling rod 2 from the upper end of drill pipe 2, and the upper end of described main helical blade 3 and The flange plate 1 is fixedly connected;

[0055] The upper end of the auxiliary helical blade 301 is located in the middle of the main helical blade 3 , and the lower end of the auxiliary helical blade 301 extends to the middle of the drill pipe 2 .

[0056] The main heli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com