Bidirectional stirring pile machine

A technology of two-way mixing and pile driving, which is applied in the direction of sheet pile walls, drilling equipment, drilling equipment and methods, etc., can solve the problems of waste of cement, uneven pile diameter, poor pile quality, etc., and achieve the reduction of cement consumption and saving The effect of improving construction cost and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

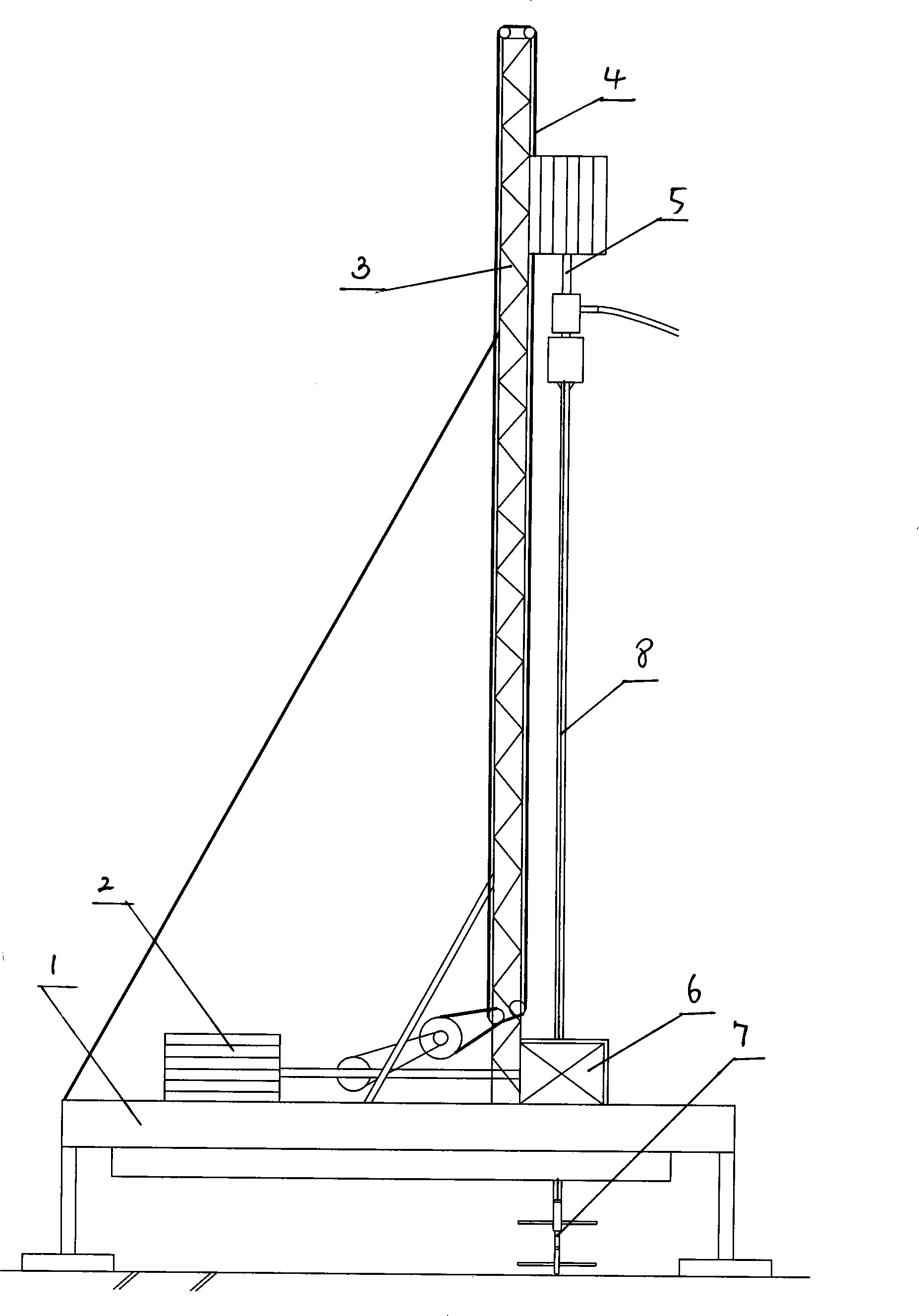

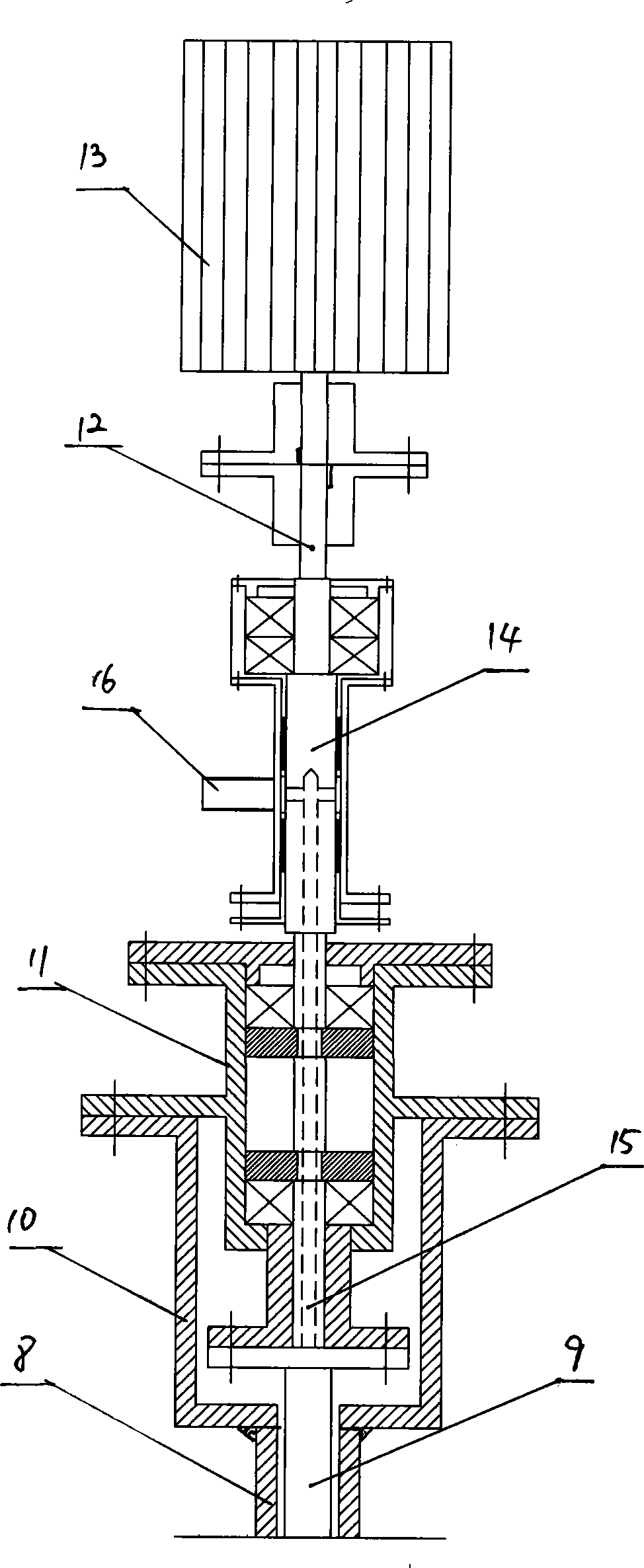

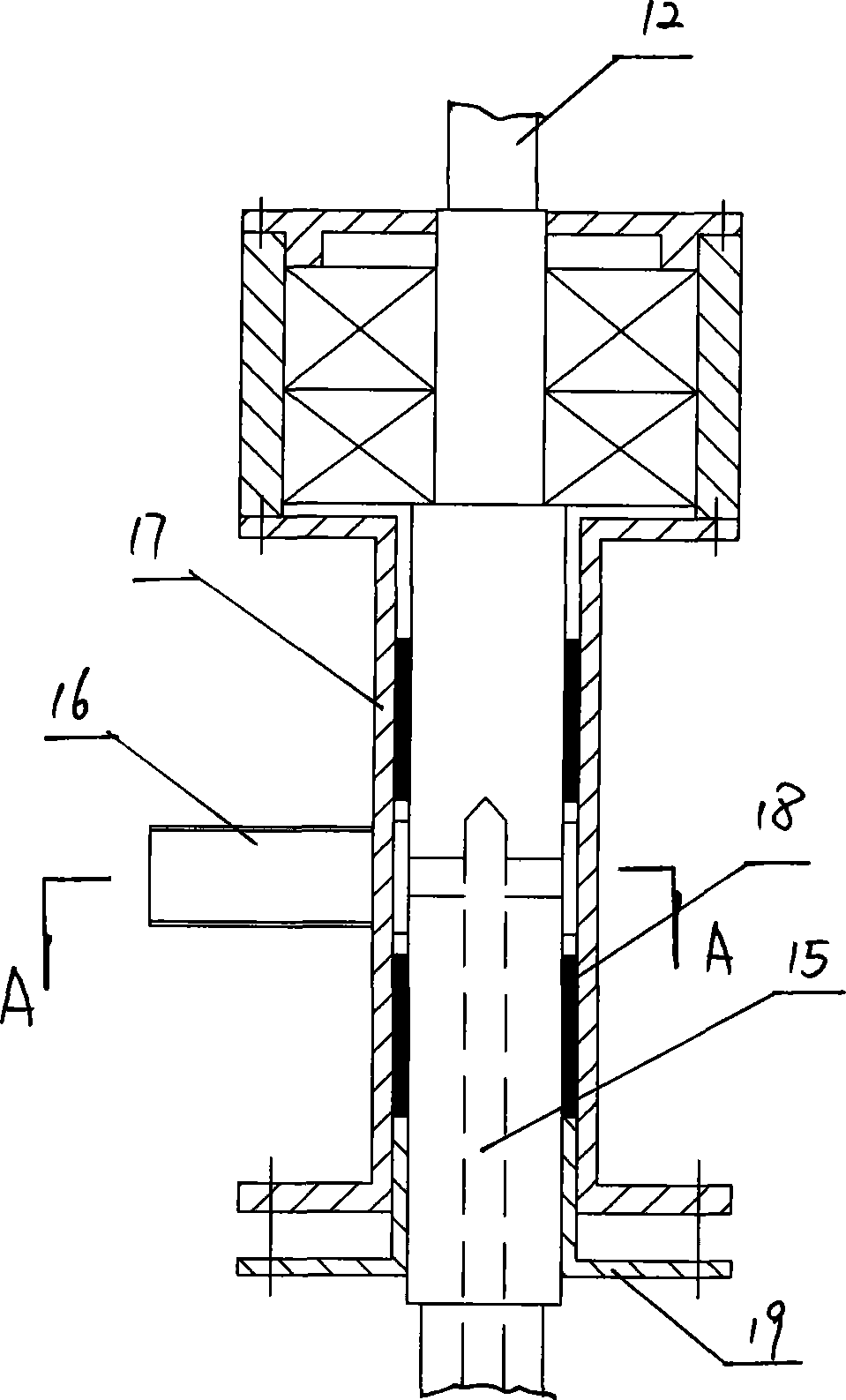

[0017] The two-way powder mixing machine of the present invention is a pile-forming mode of stirring in two opposite directions, and is realized by a drill rod composed of coaxial inner and outer drill rods 9,8. The cross-sectional shape of the outer drill rod 8 is square or hexagonal, and the rotation of the outer drill rod 8 is transmitted through the turntable 6, and the transmission point of the outer drill rod 8 is at the lower part of the drill rod; the cross-sectional shape of the inner drill rod 9 is circular, and the inner drill rod 9 The rotation of the drill rod 9 is driven by the upper transmission motor 13, and the transmission point of the inner drill rod 9 is on the top of the drill rod. The bottoms of the inner and outer drill rods are respectively connected with inner and outer drill bits with double-layer stirring blades.

[0018] The specific structure is: including the chassis 1, the tower frame 3, the inner and outer drill pipes set together, the drill bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com