Immersed tube grout pile construction process and pile tip bearing capacity reinforcement equipment

A technology of pile tip bearing capacity and sinking cast-in-situ piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of weakening pile tip bearing capacity, achieve improved pile tip bearing capacity, simple structure, and improve construction Effects of efficiency and pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

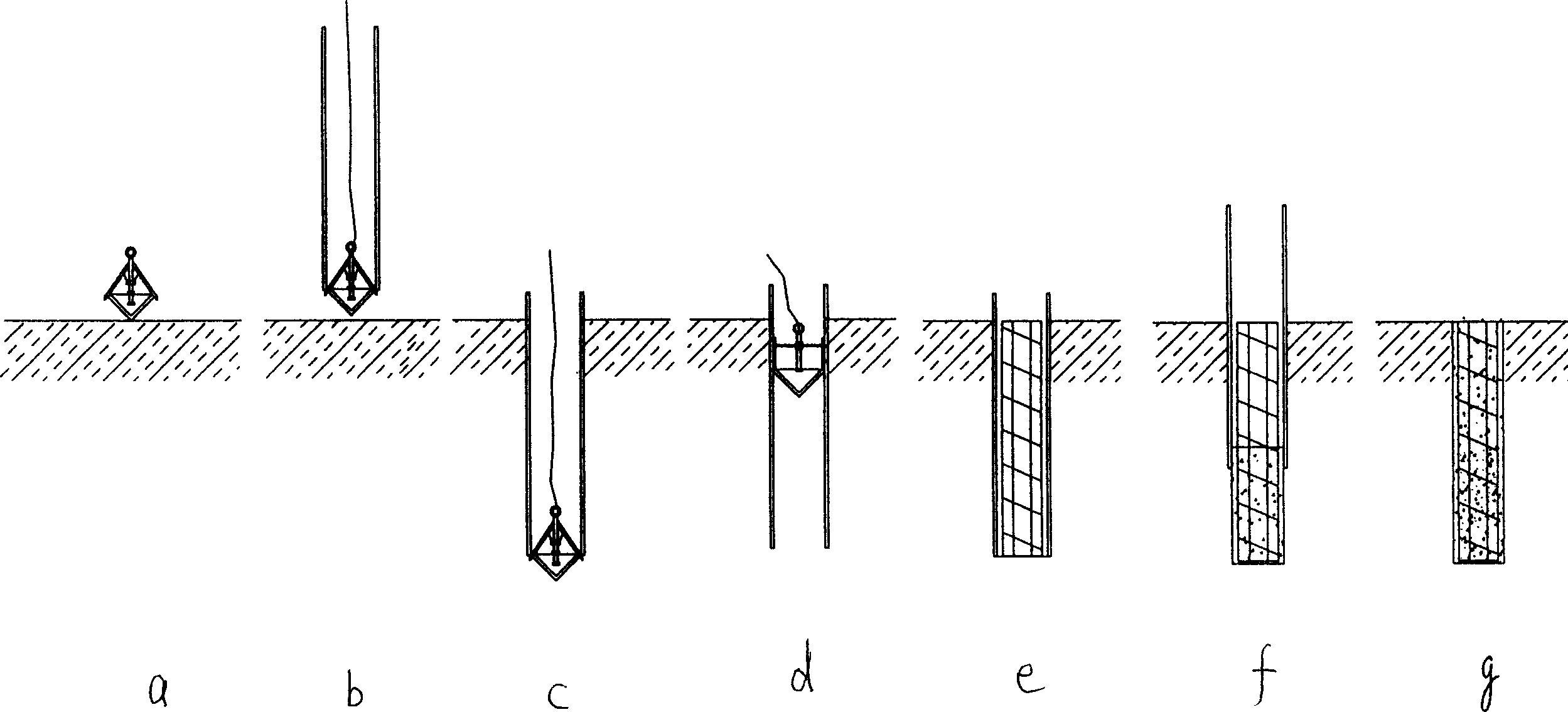

[0049] Embodiment: The construction technology of sinking pipe grouting pile is as follows figure 1 Shown:

[0050] Step a: installing a pile end bearing capacity enhancer at the anchor point of the pile foundation;

[0051] Step b: Put the pile driver in place, align the lower end of the steel casing with the pile end bearing capacity enhancer, and ensure the verticality;

[0052] Step c: Immerse the tube to the design position;

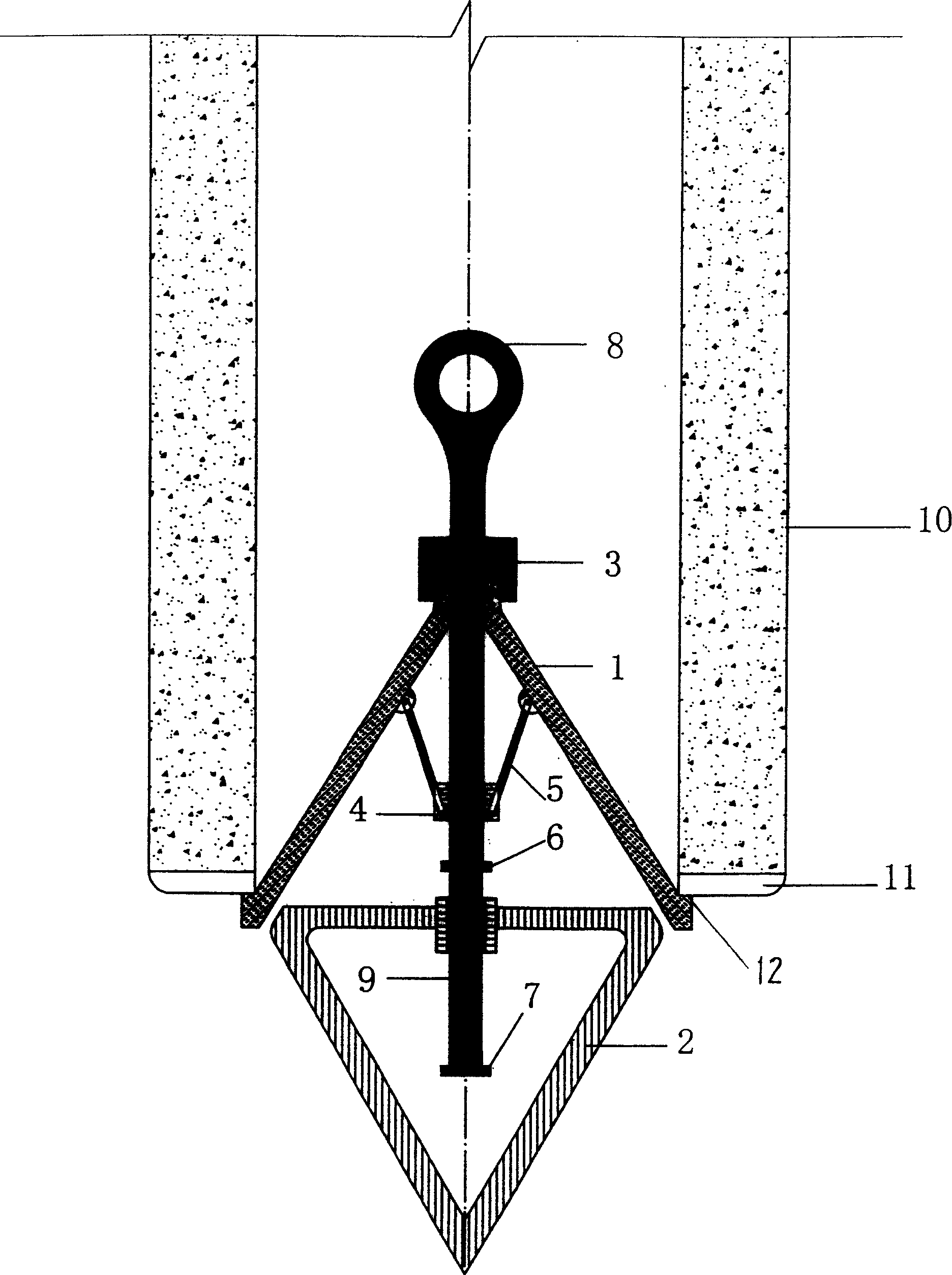

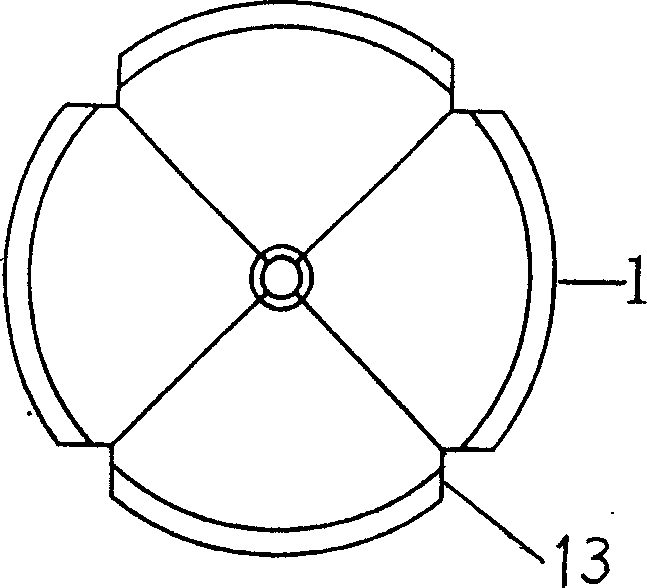

[0053] Step d: pull the lifting rope connected to the pile end bearing capacity enhancer from the top of the steel casing, drive the central axis umbrella pole 9 connected with the handle 8, first lift the top cap 3, release the constraint on the diagonal brace 1, and continue to lift , the fixed block 6 drives the movable slider 4, so that the support connecting rod 5 pushes the diagonal brace 1 around to make it parallel to the pile wall, the lower end of the diagonal brace also shrinks into the pipe pile, and continues to lift, and the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com