Pile work equipment

A kind of equipment and piling technology, which is applied in the direction of drilling equipment, sheet pile wall, foundation structure engineering, etc., can solve the problems of affecting piling efficiency, difficulty in deploying equipment, and high requirements for construction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0050] As shown in the figure, it is a preferred embodiment of the present invention.

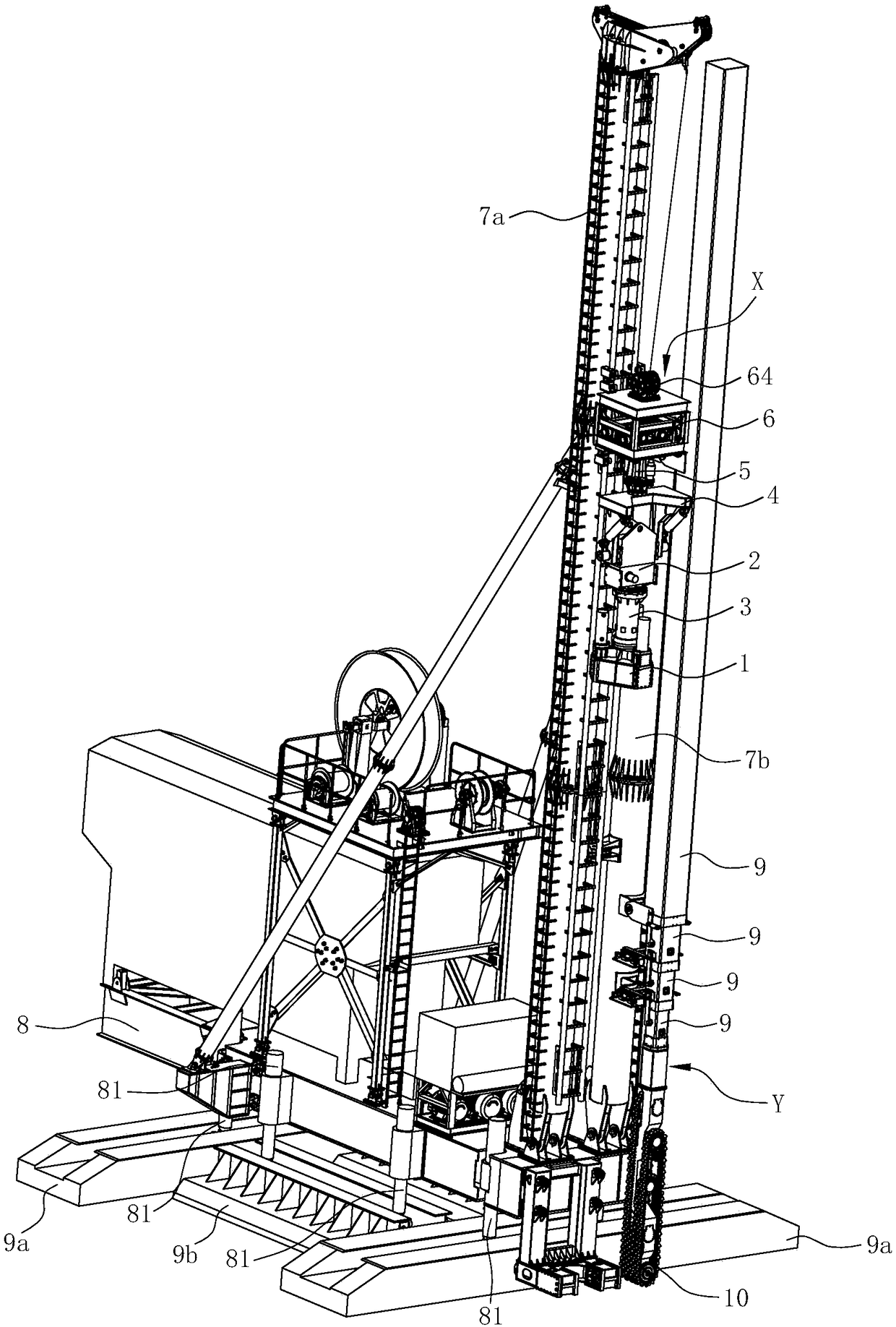

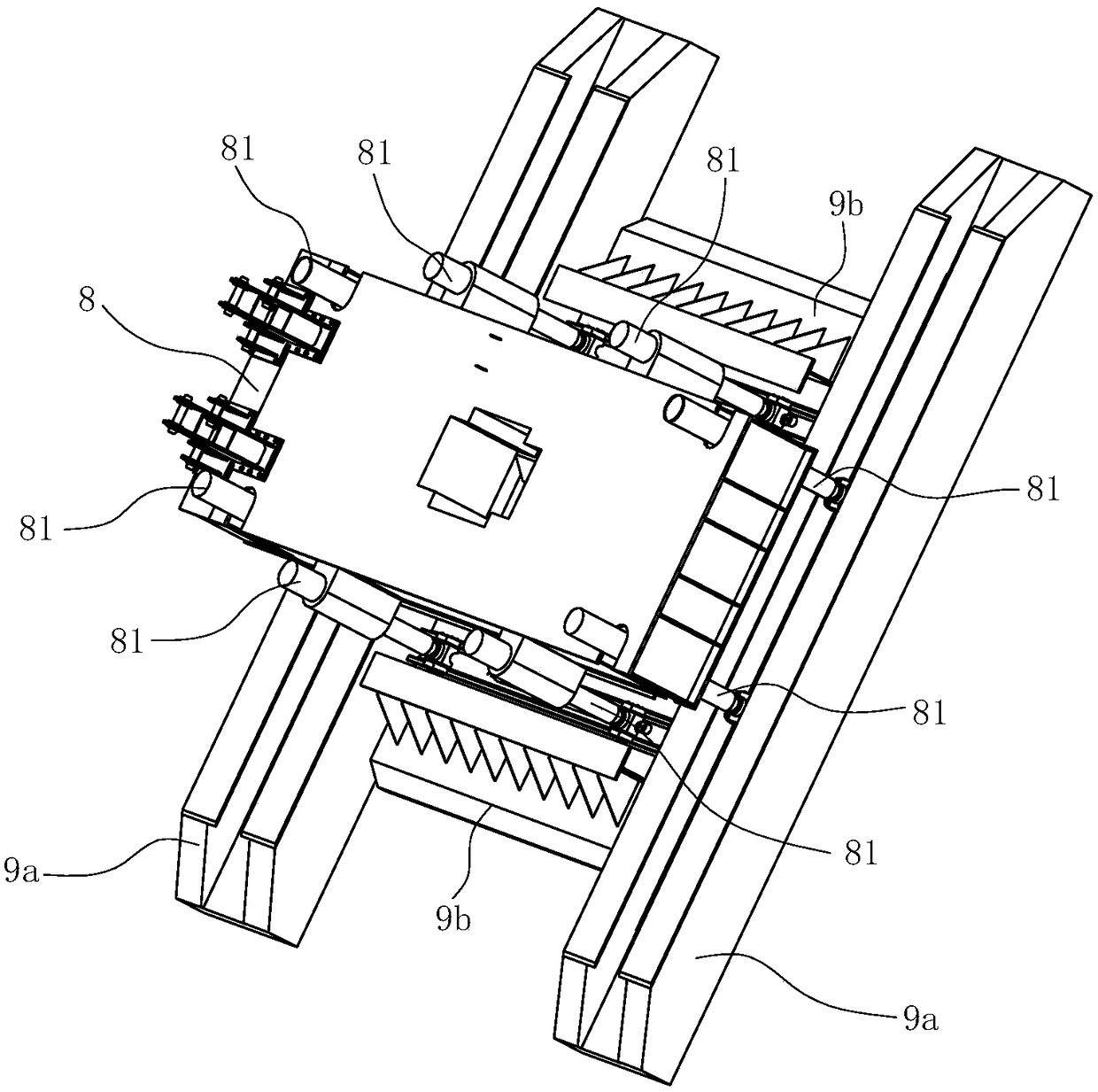

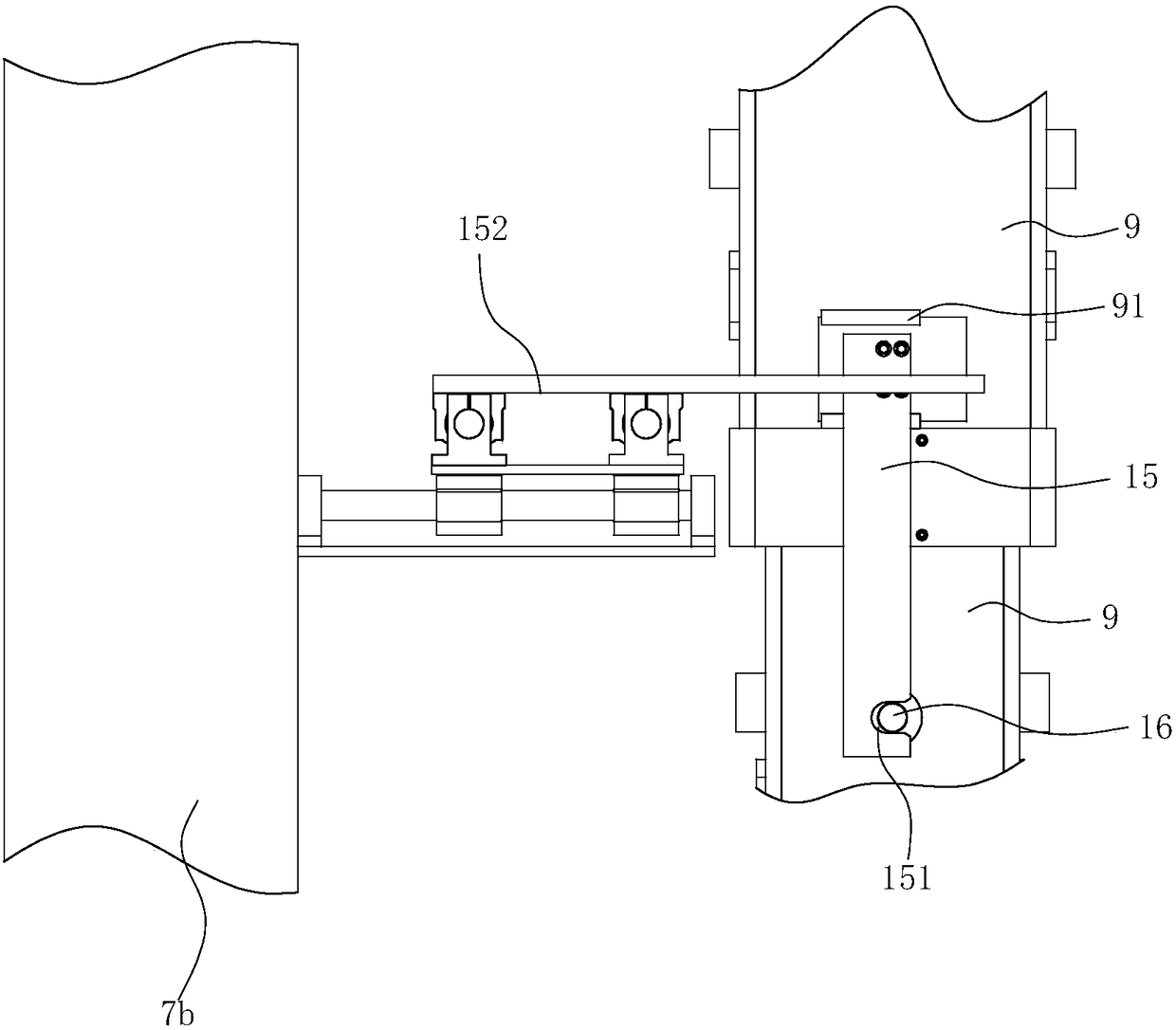

[0051] A kind of piling equipment, including a working platform 8, the bottom of the working platform 8 is provided with a plurality of sets of supporting legs 81, and the supporting legs 81 are telescopic leg structures that can be stretched up and down. The supporting legs 81 are respectively arranged on the two transverse large ships 9a arranged at intervals before and after, and the horizontal large ship 9a is provided with a transverse drive structure for driving the working platform 8 to slide left and right with the supporting legs 81 relative to the horizontal large ship 9a, such as the supporting legs 81 The lower end is installed on the horizontal large ship 9a by the slide plate guide rail structure, and the driving structure can refer to the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com