Threaded screwing inserting bar compaction filling pile

A technology of cast-in-situ piles and reinforcements, which is applied to sheet pile walls, drilling equipment, earthwork drilling and mining, etc., can solve problems such as inapplicability, inapplicability to foundation engineering, and lack of rock-socketing ability, achieving high efficiency and strong pile formation The effect of rock socket function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

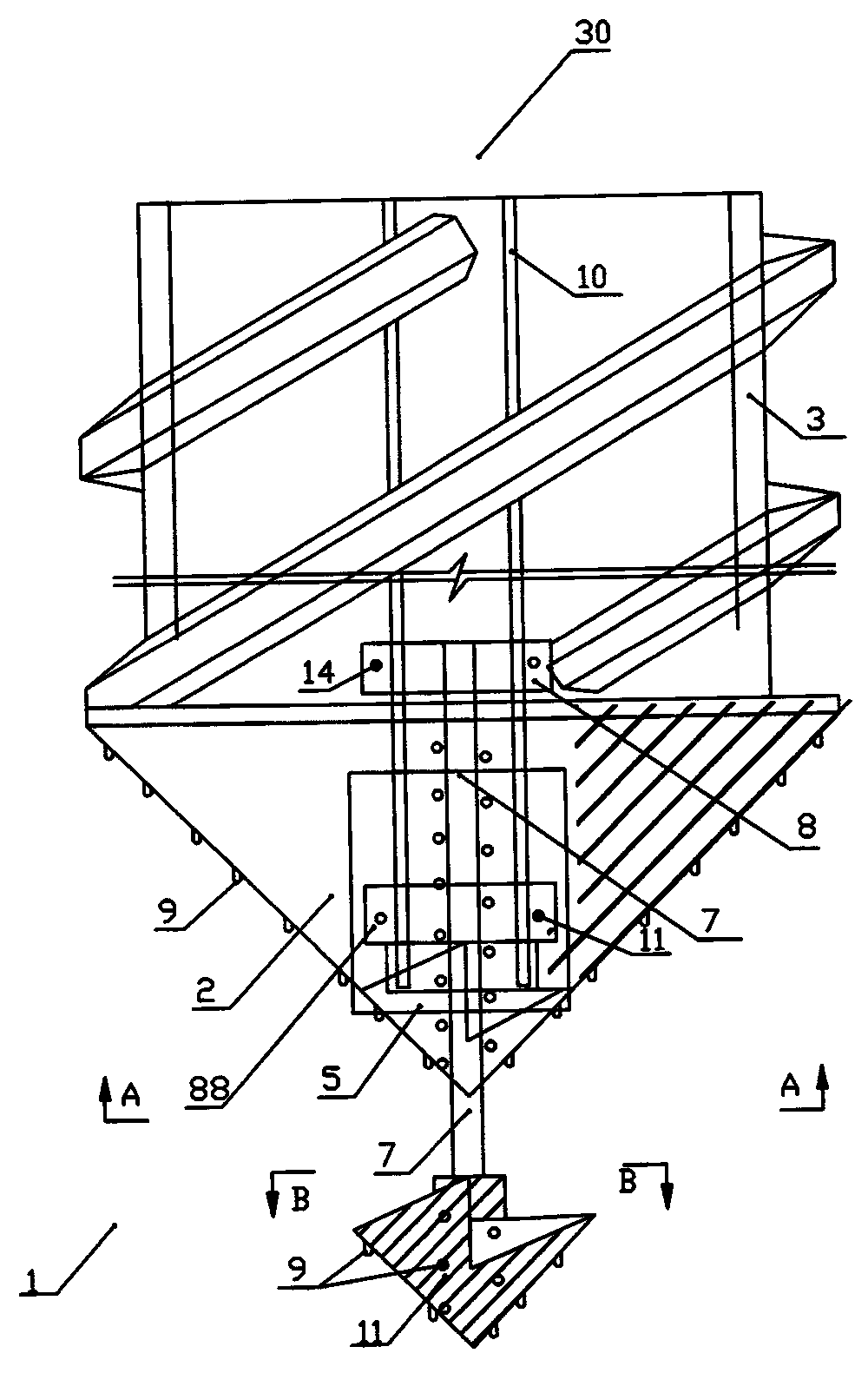

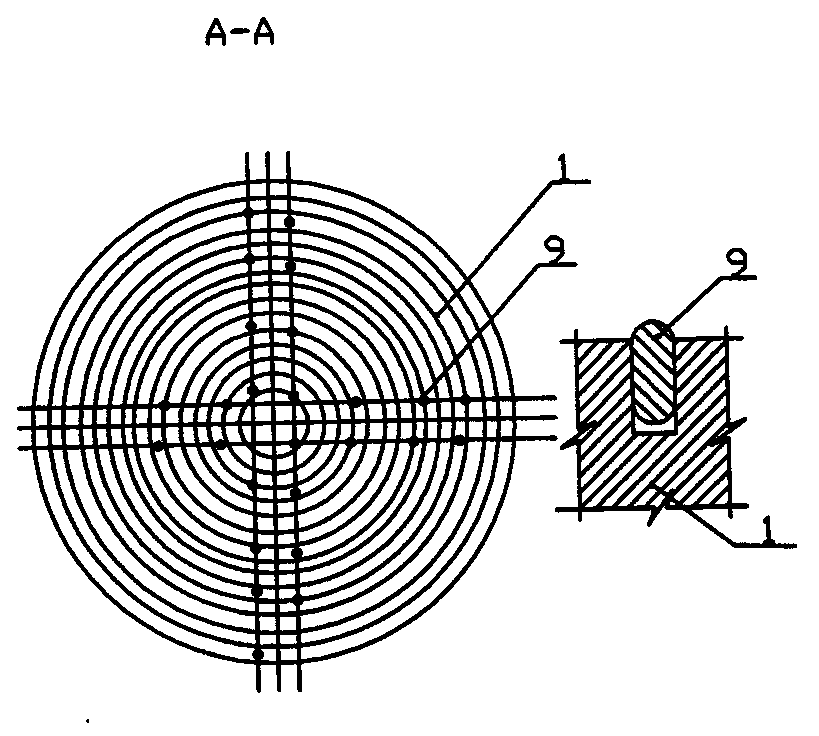

[0027] Such as Figure 1 to Figure 6 As shown, this embodiment specifically adopts the following structure: a rock-socketed drill bit 30 is included. In order to improve the ability of penetrating each layer of soil in the hill formation, the rock-socketed drill bit 30 is composed of a drill bit tip 1 at the lower end, a drill bit body 2 at the upper part and a trapezoidal threaded short pipe 3;

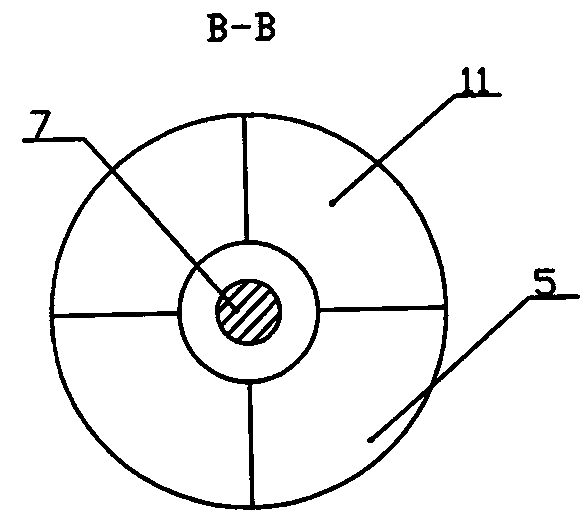

[0028] The upper and lower joints 5 are arranged between the drill tip 1 and the drill body 12. When the drill body 2 reverses 90°, the upper and lower joints are disengaged, and the drill tip 1 is separated from the upper drill body 2; Joint connection, that is, the drill tip and the drill body are integrated into one;

[0029] The drill bit body 2 is fixedly connected with the trapezoidal thread short pipe 3;

[0030] The upper end of the trapez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com