Pile driver for construction site

A technology for construction sites and pile drivers, which is used in construction, sheet pile walls, infrastructure engineering, etc., can solve the problems of poor straightness of pile drivers, inclined driving of wooden piles into the ground, and low efficiency of wire rope lifting, and achieves up and down reciprocating motion. The effect of smoothness, increasing service life and improving piling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

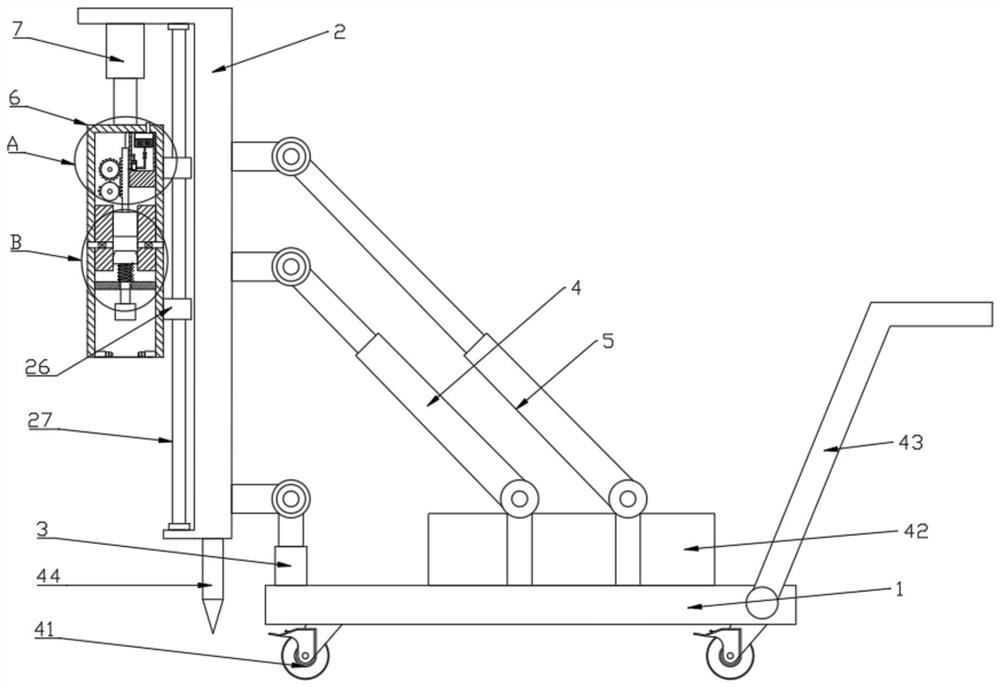

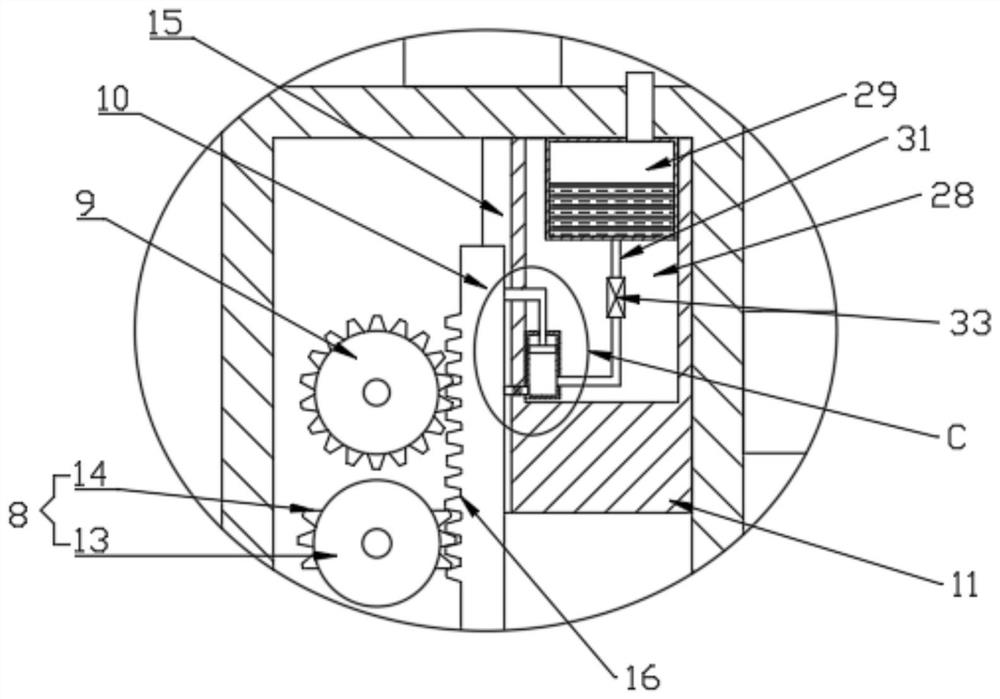

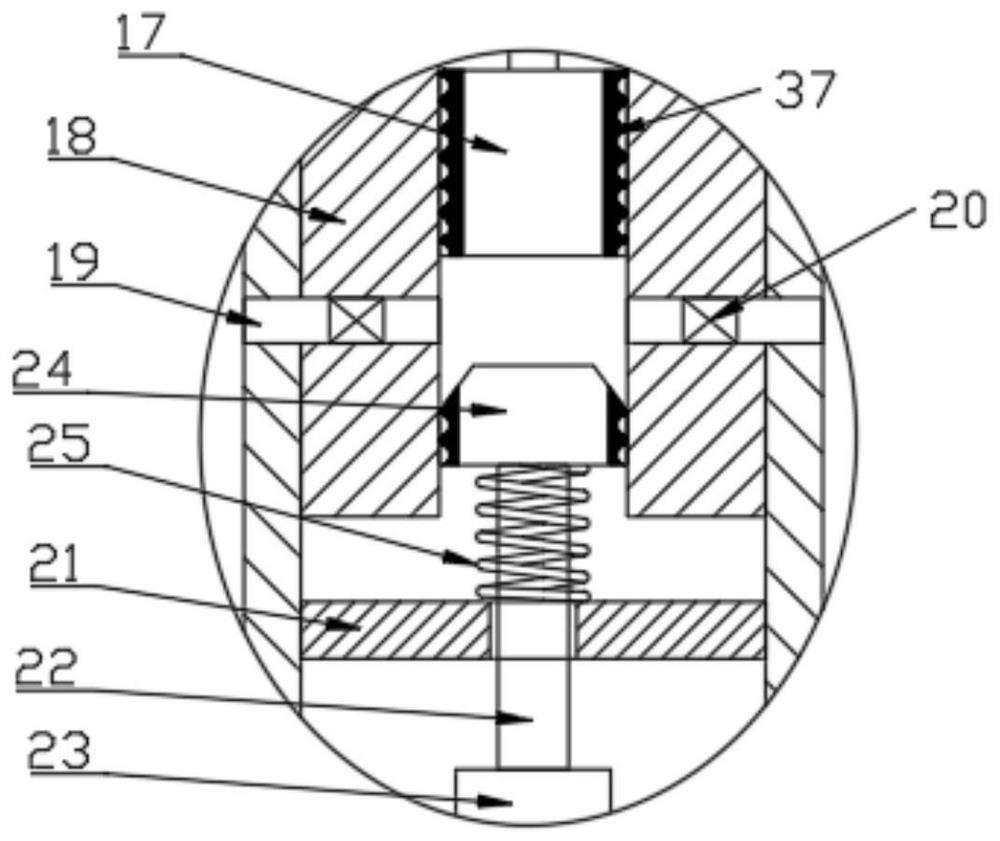

[0026] see Figure 1-3 , a pile driver for a construction site, a pile driver for a construction site, comprising a base plate 1, a bracket 2 and a piling mechanism, the top surface of the base plate 1 passes through an electric hydraulic cylinder one 3, an electric hydraulic cylinder two 4 and an electric hydraulic cylinder The third 5 is connected to the bottom surface of the support 2, the output ends of the electric hydraulic cylinder one 3, the electric hydraulic cylinder two 4 and the electric hydraulic cylinder three 5 are all hinged with the bottom surface of the support 2, and the electric hydraulic cylinder two 4 and the electric hydraulic cylinder three 5 are inclined Set, described piling mechanism comprises piling cylinder 6, driving mechanism and clamping mechanism, and described piling cylinder 6 is connected with support 2 top by electro-hydraulic cylinder 47, and described driving mechanism comprises first gear 8, second gear 9, The guide rod 10 and the slidin...

Embodiment 2

[0033] This embodiment has been improved on the basis of Embodiment 1, specifically:

[0034] A cavity 28 is provided in the sliding box 11, and a lubricating mechanism is provided in the cavity 28. The lubricating mechanism includes an oil storage tank 29 and an oil outlet cylinder 30, and the oil storage tank 29 is fixed on the top of the cavity 28. , and the oil storage tank 29 communicates with the outside of the piling barrel 6 through the infusion tube, the oil outlet barrel 30 is fixed on the side of the cavity 28, and the bottom of the left side of the oil outlet barrel 30 is connected to the bottom of the oil storage tank 29 through the first connecting pipe 31 The bottom of the right side of the oil outlet cylinder 30 communicates with the chute 15 through the second connecting pipe 32, and the first connecting pipe 31 is equipped with a first one-way passage 33 that only allows lubricating oil to flow to the oil outlet cylinder 30 , the second connecting pipe 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com