Self-elevating ocean platform pile shoe pile jetting system capable of preventing jetting pipeline from being blocked

An offshore platform, self-elevating technology, applied in the field of offshore platforms, can solve the problems of difficulty in pulling out piles, poor pile punching effect, etc., and achieve the effects of reducing the number of punching holes, high jetting pressure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

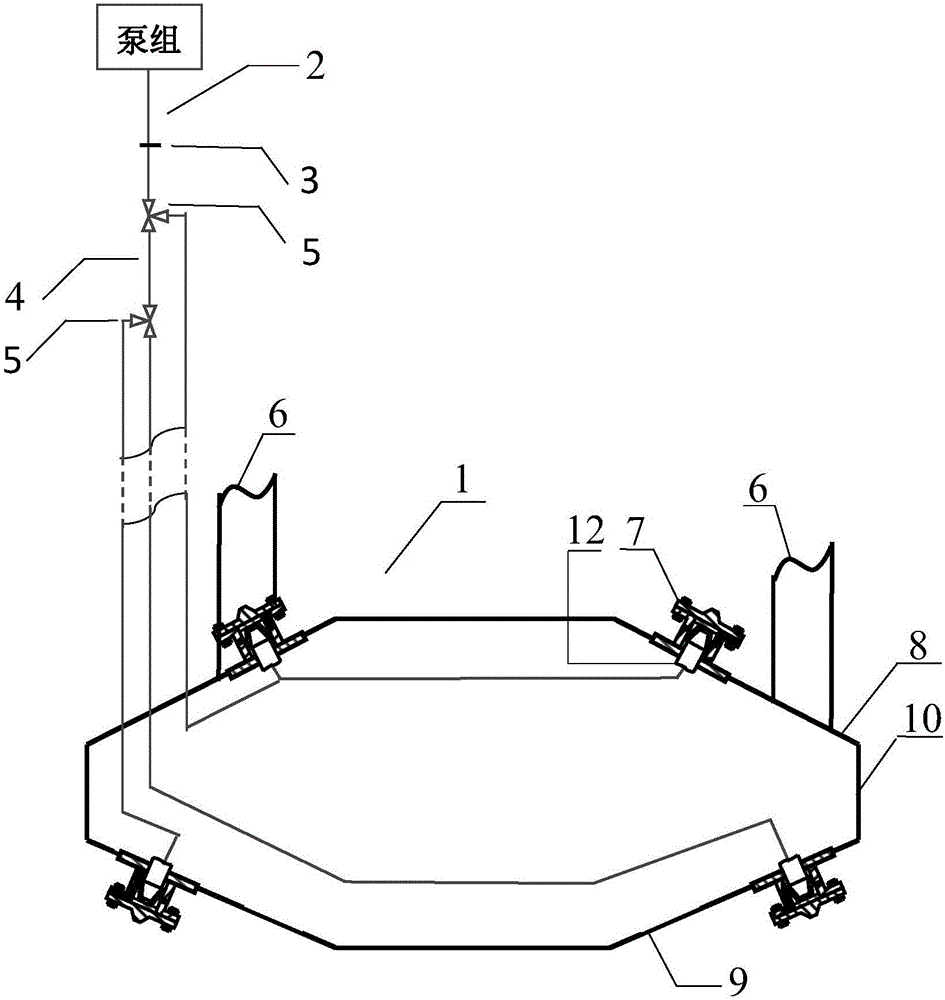

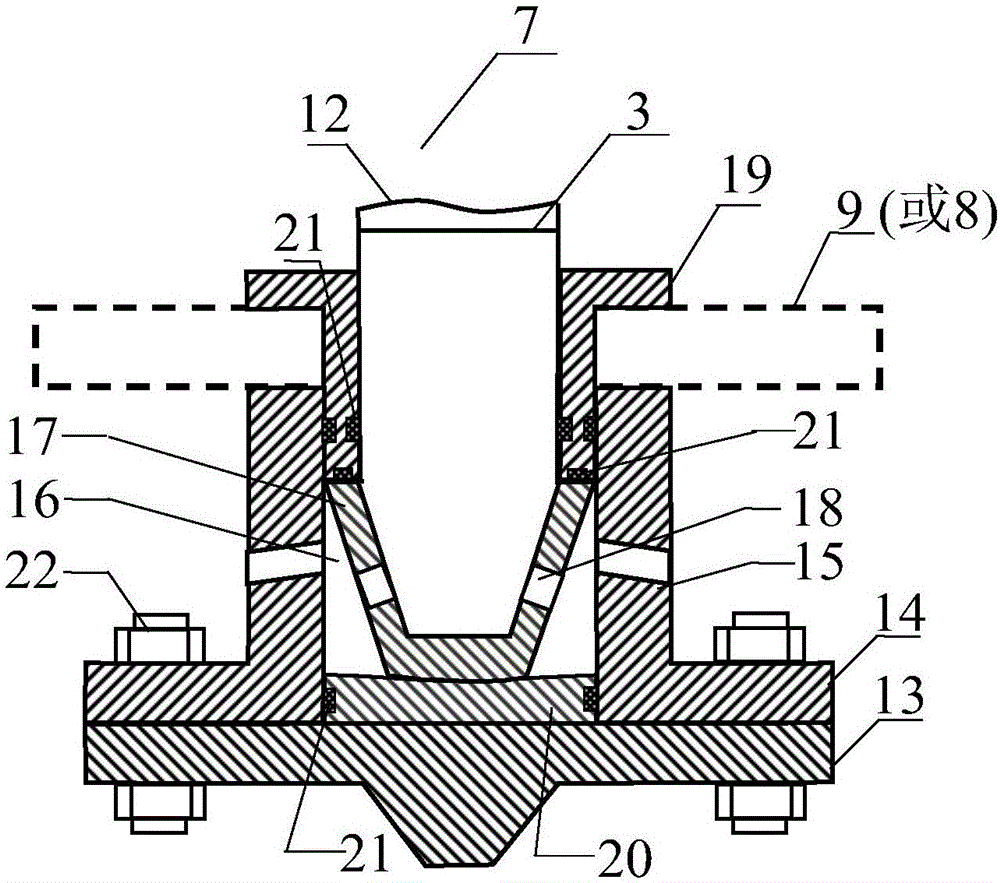

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

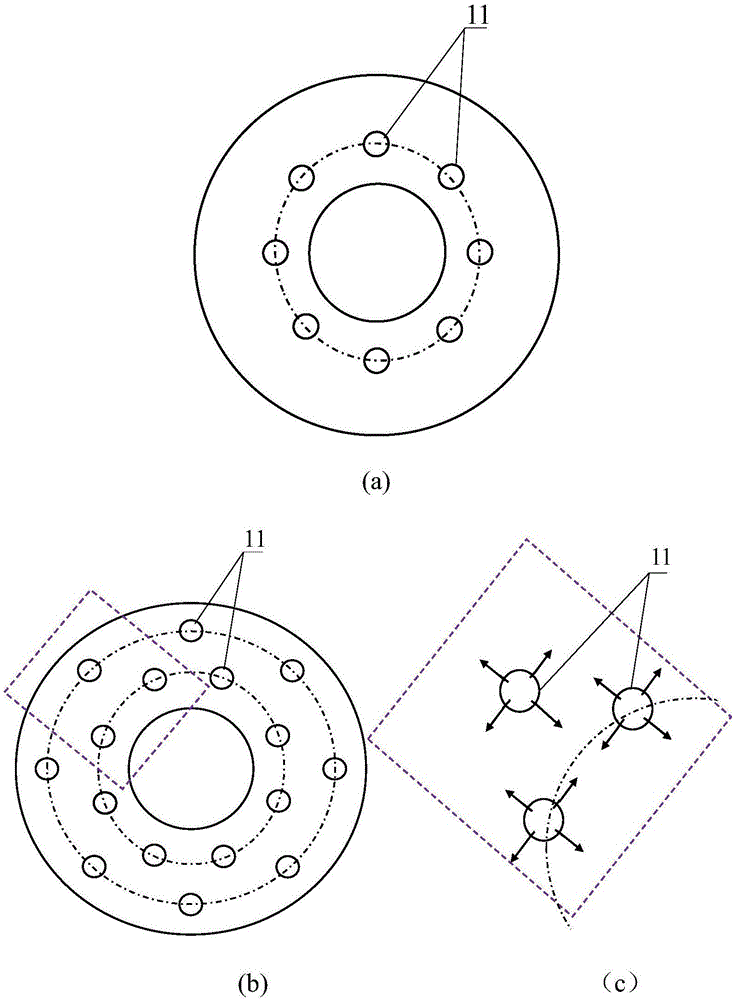

[0023] refer to figure 1 , image 3 , a self-elevating offshore platform spud shoe flushing system for preventing the pile flushing pipeline from clogging, comprising a spud shoe 1 and a truss type leg 6 fixedly connected to the upper end of the spud shoe 1 , the shell of the spud shoe 1 is formed by an upper top plate 8 , the lower bottom plate 9 and the side plate 10, a circle of punching pile holes 11-1 is arranged at an interval of 45° on the upper top plate 8, and two circles of punching pile holes 11-2 are arranged at an interval of 45° on the lower bottom plate 9. The initial positions of the punching holes 11-2 are spaced at 22.5°, and a closed pile punching nozzle 7 is arranged on the outside of each upper and lower punching pile hole 11, and is fixed on the upper top plate 8 and the lower surface of the pile shoe 1 by welding. The bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com