Piling barge

a technology of piling barge and sluice barge, which is applied in the field of piling barge to achieve the effects of facilitating the adjustment of the pile position, and improving the working efficiency of the piling barg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

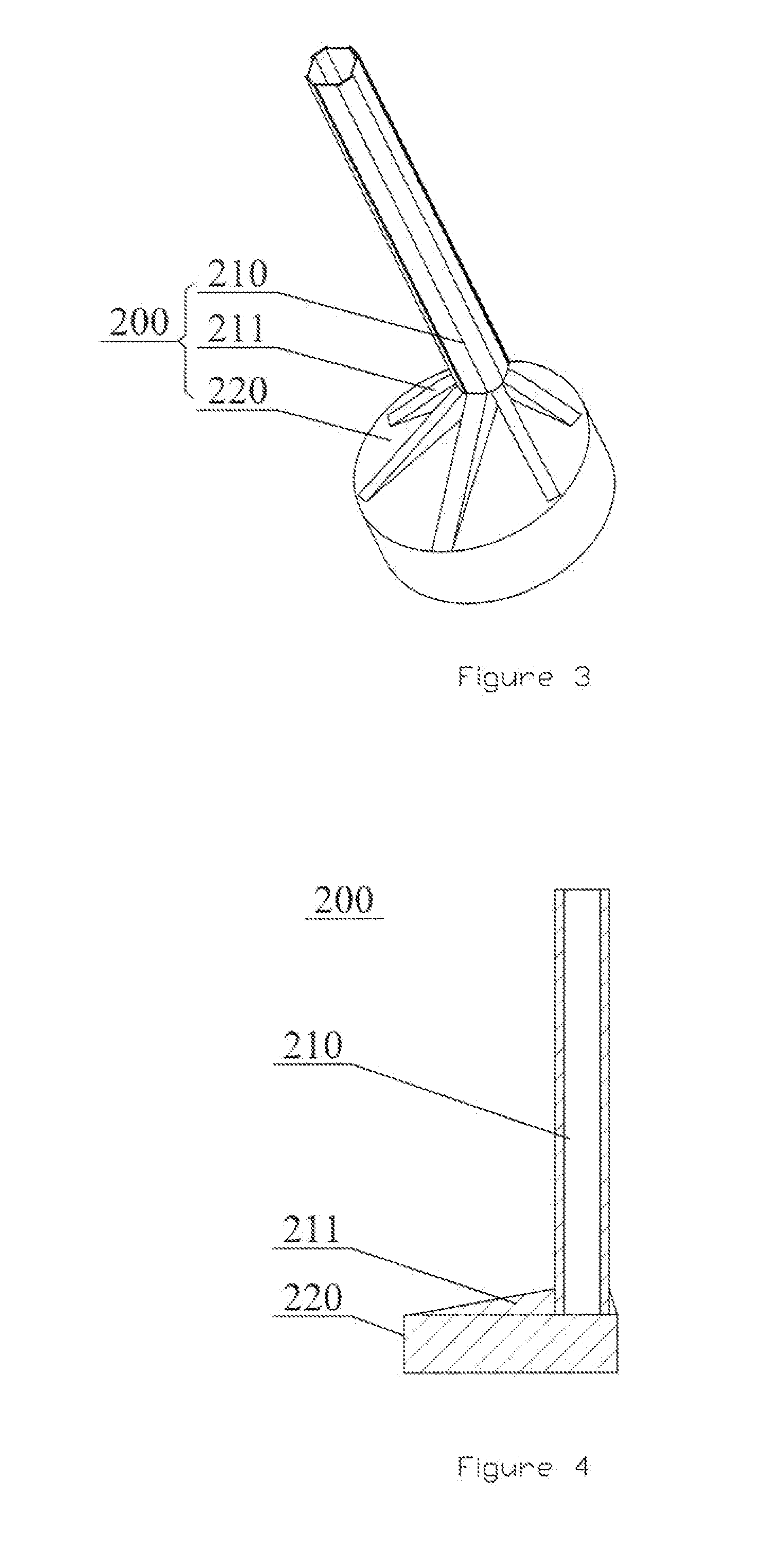

[0049]Reference is made to FIG. 7, which is a structural schematic view of the supporting leg in the piling barge provided by the prevent invention.

[0050]As compared with the first supporting leg, one of the differences in the second supporting leg is that the supporting base 220 includes a cavity 221 having an opening at the bottom surface of the supporting base 220. Following is the working principle of the supporting leg 200. When the supporting leg 200 needs to be lowered and supported on the seabed ground, a suitable charging and discharging pump may be used to depressurize the cavity 221, discharge air and water inside the cavity 221, and thus establish a negative pressure therein, such that the supporting leg 200 is lowered smoothly and sunk through to the seabed ground, therefore providing a supporting force for the hull 100; when the supporting leg 200 needs to be separated from the mollisol ground 300 after a predetermined offshore operation being finished, the charging an...

third embodiment

[0053]It can be appreciated that the cavity 221 may be pressurized or depressurized, as long as the outer port of the charging and discharging passage 222 is positioned on the outer surface of the supporting base 220 and the inner port thereof is on the wall of the cavity 221. Therefore, the outer port of the charging and discharging passage 222 may be positioned at other portions of the outer surface of the supporting base 220. As shown in the structural schematic view of the supporting leg in the piling barge provided by the prevent invention in FIG. 8, herein, the outer port of the charging and discharging passage 222 is positioned between the reinforcing ribs 211 at the outer surface of the supporting base 220. In this way, the charging and discharging passage 222 can be connected with the charging and discharging pump provided on the hull 100 through the delivery pipe 230. Also, the charging and discharging pump may be disposed directly on the supporting base 220 under predeter...

fourth embodiment

[0056]Further, in specific conditions, it is also possible not to provide a charging and discharging passage, as shown in the structural schematic view of the supporting leg in the piling barge provided by the prevent invention in FIG. 9. In the supporting leg, the purpose of pressurizing and depressurizing the cavity 221 may also be achieved with the delivery pipe 230 entering into the cavity 221 across the bottom surface of the supporting base 220.

[0057]The structure of the piling device in the piling barge will be described below.

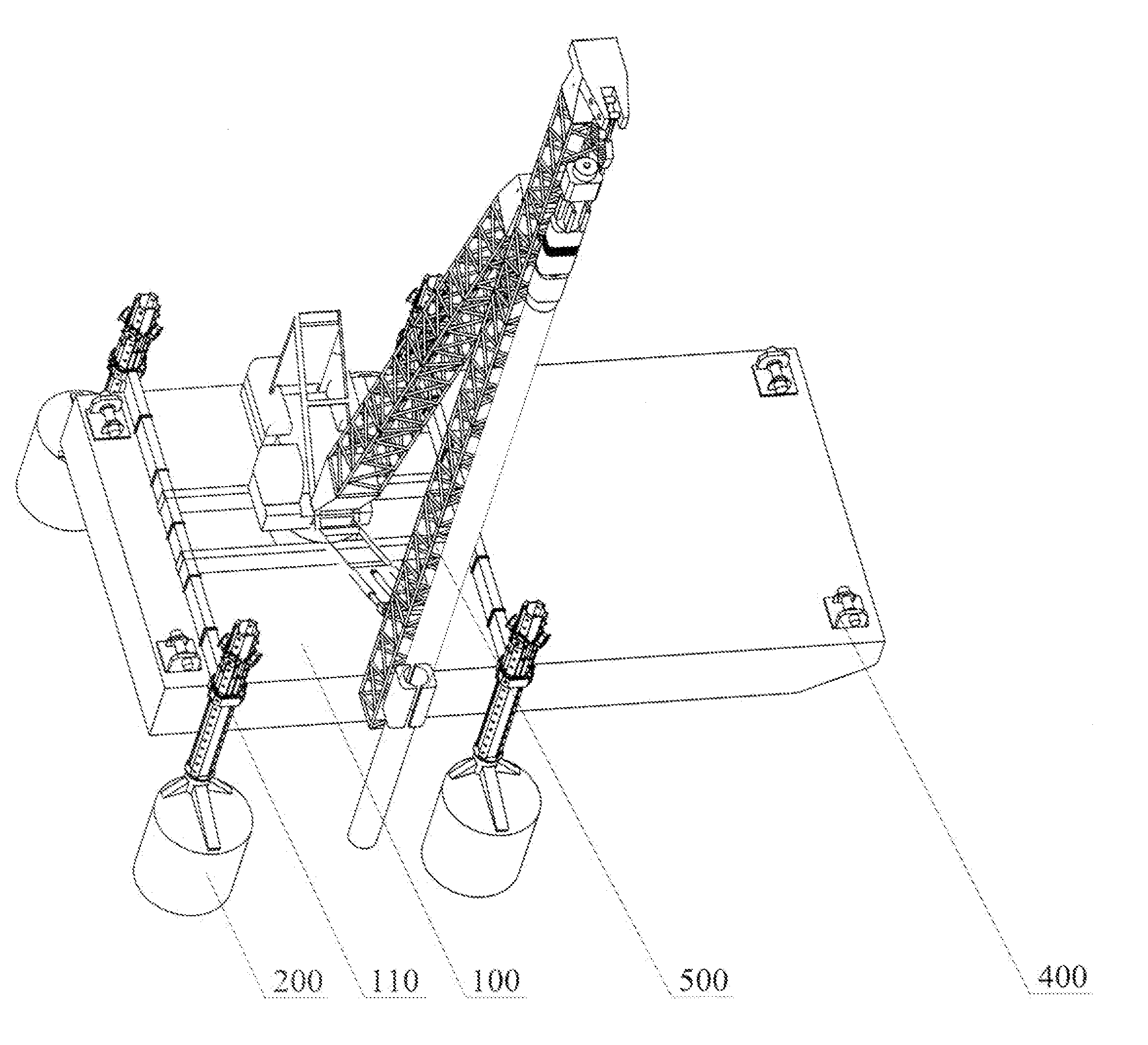

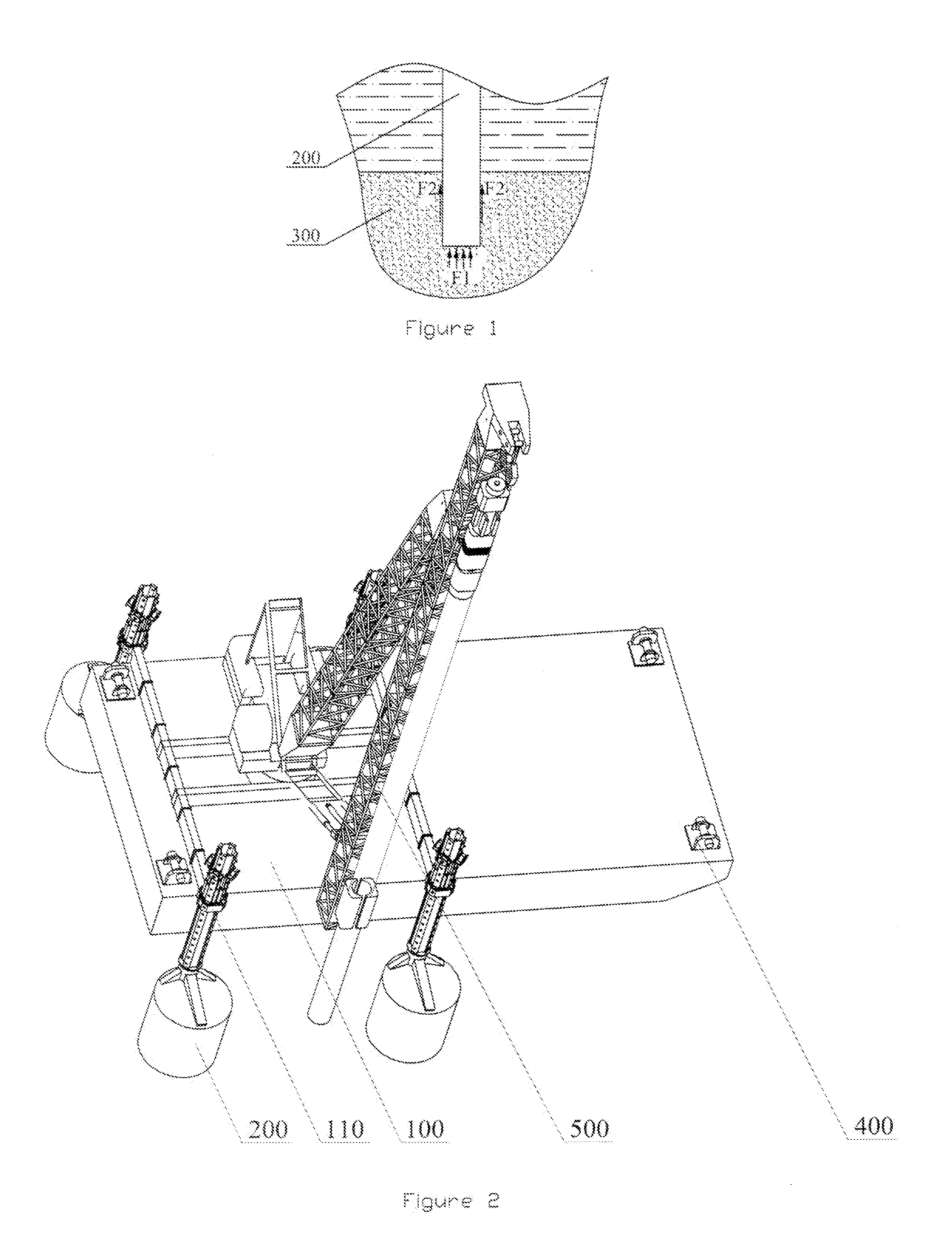

[0058]Reference is made to FIG. 10, which is a side structural schematic view of the piling barge provided by the present invention. The piling device 500 includes a pile frame 510, a hanging hook 520, a boom 530, a turntable 550 and a luffing oil cylinder 540. The turntable 550 is mounted on the hull 100 by means of a turning mechanism, and may be driven to rotate around a vertical axis relative to the hull 100 by a hydraulic motor. One end of the luffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com