Power-supply controller of electric dust collector and long-range control system of the same

A technology of electrostatic precipitator and power controller, applied in electrical program control, electrostatic separation, comprehensive factory control, etc., can solve problems such as slow transmission rate, poor communication reliability, and inability to find the best one, achieving fast speed and improved accuracy The effect of improving reliability and communication reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

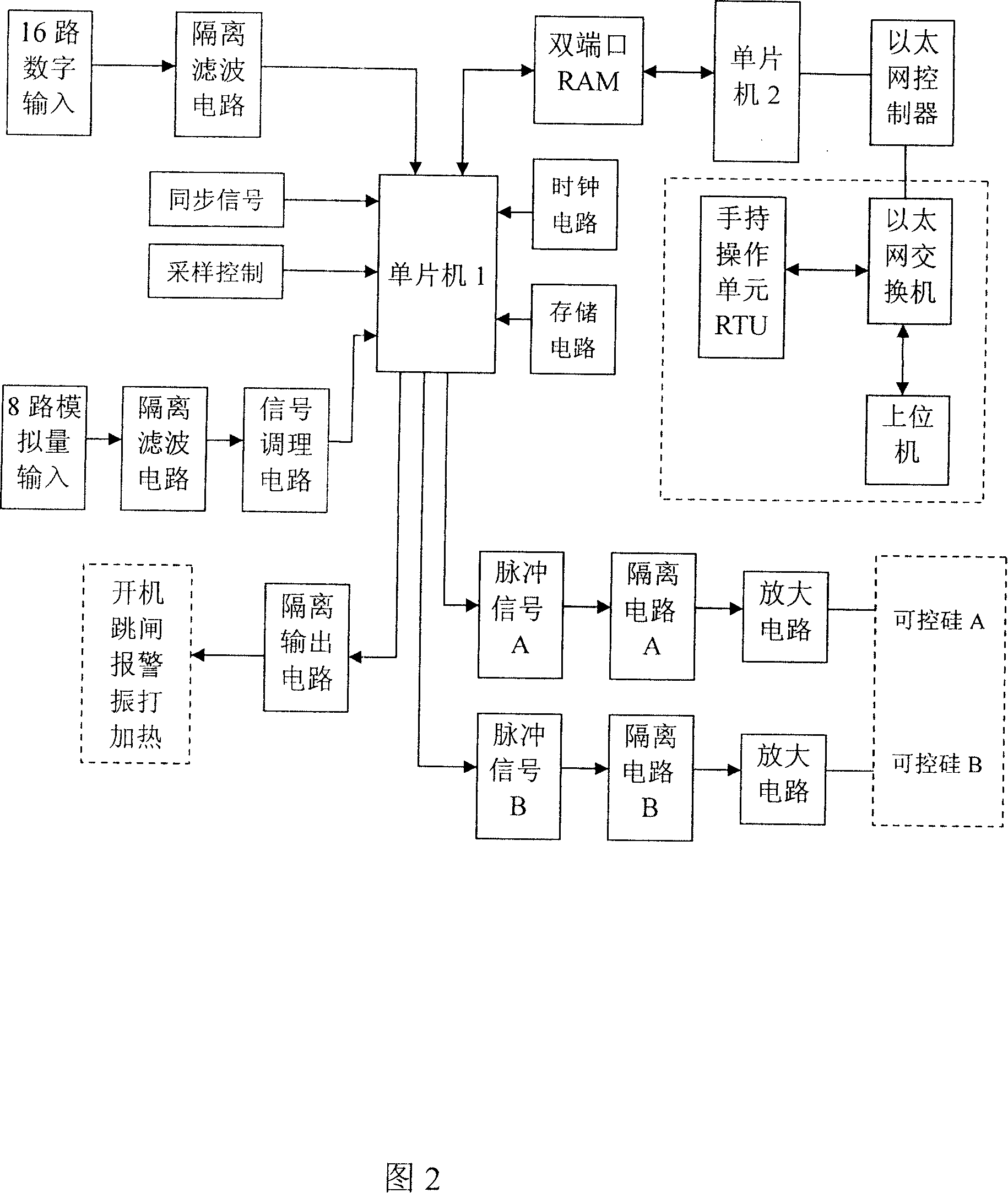

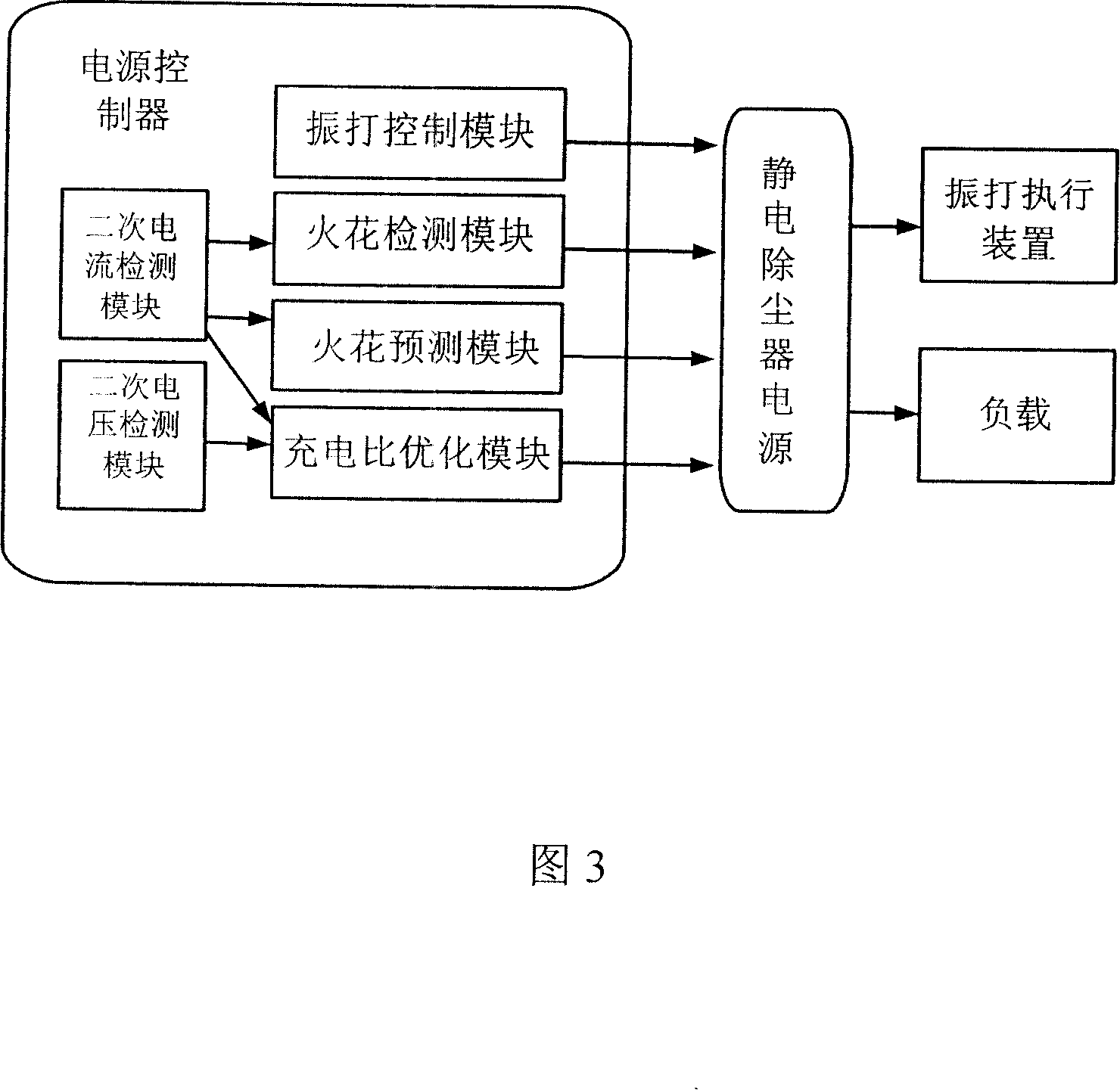

[0040] Please refer to Fig. 2, Fig. 2 is the hardware structural representation of the electrostatic precipitator power controller system of the embodiment of the present invention; The electrostatic precipitator power controller inside comprises a circuit board, and it comprises: 24V direct current power supply, the single-chip microcomputer 1 of control usefulness, Clock circuit, storage circuit, sampling control circuit, multi-channel analog input, multiple digital input, and pulse signal A and pulse signal B output circuits for controlling the operation of thyristor A and thyristor B, etc. The power supply of the electrostatic precipitator consists of a control box, a step-up transformer and a rectifier. SCR A and SCR B are used to control the power supply mode and amplitude of the power supply (not shown in the figure) of the electrostatic precipitator. The cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com