Vehicular mirror system

a mirror system and rearview mirror technology, applied in the field of interior rearview mirror assembly, can solve the problems of affecting the vibration performance of the mirror assembly, not being widely used, and crowding out other accessories, and achieve the effect of improving vibration characteristics and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

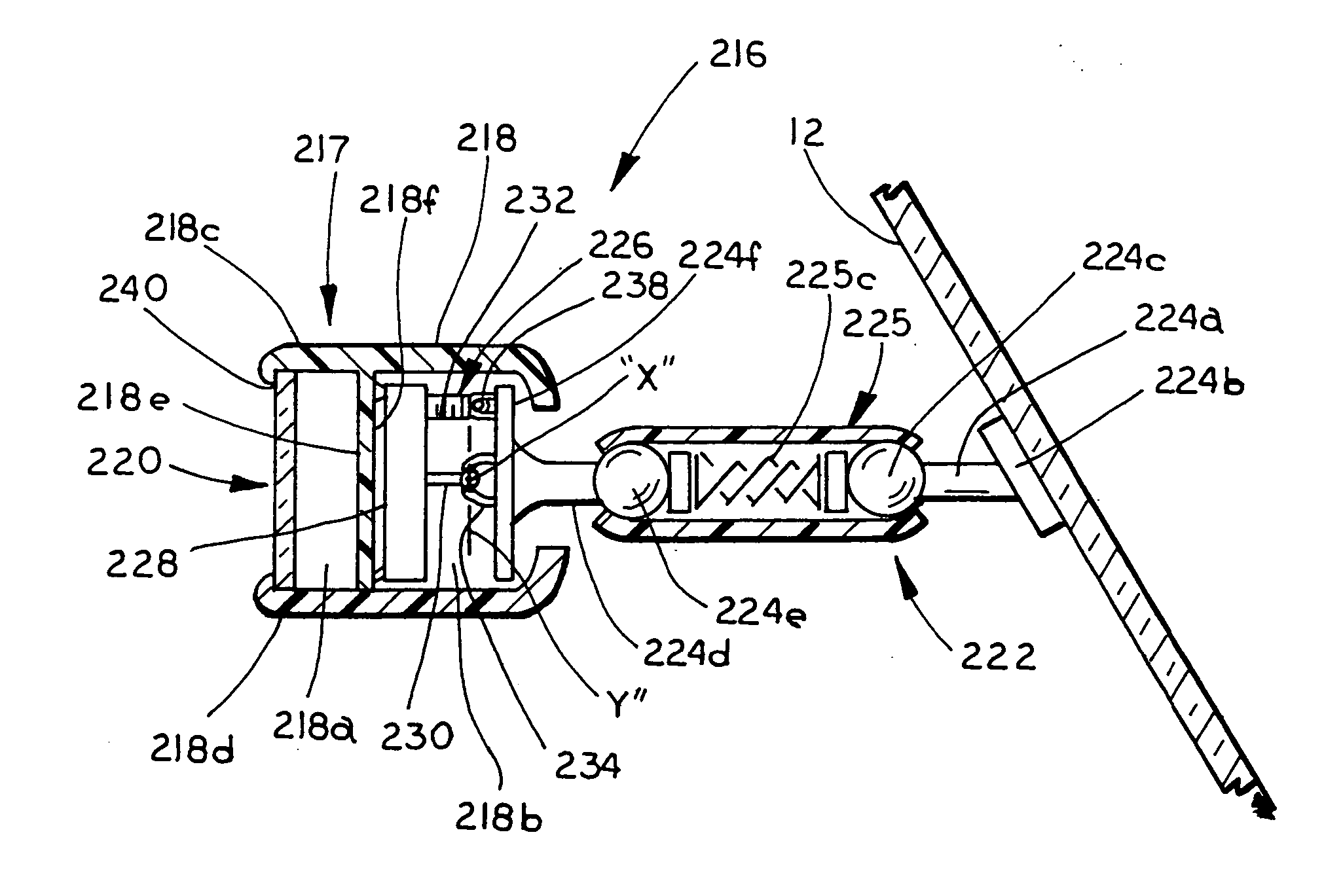

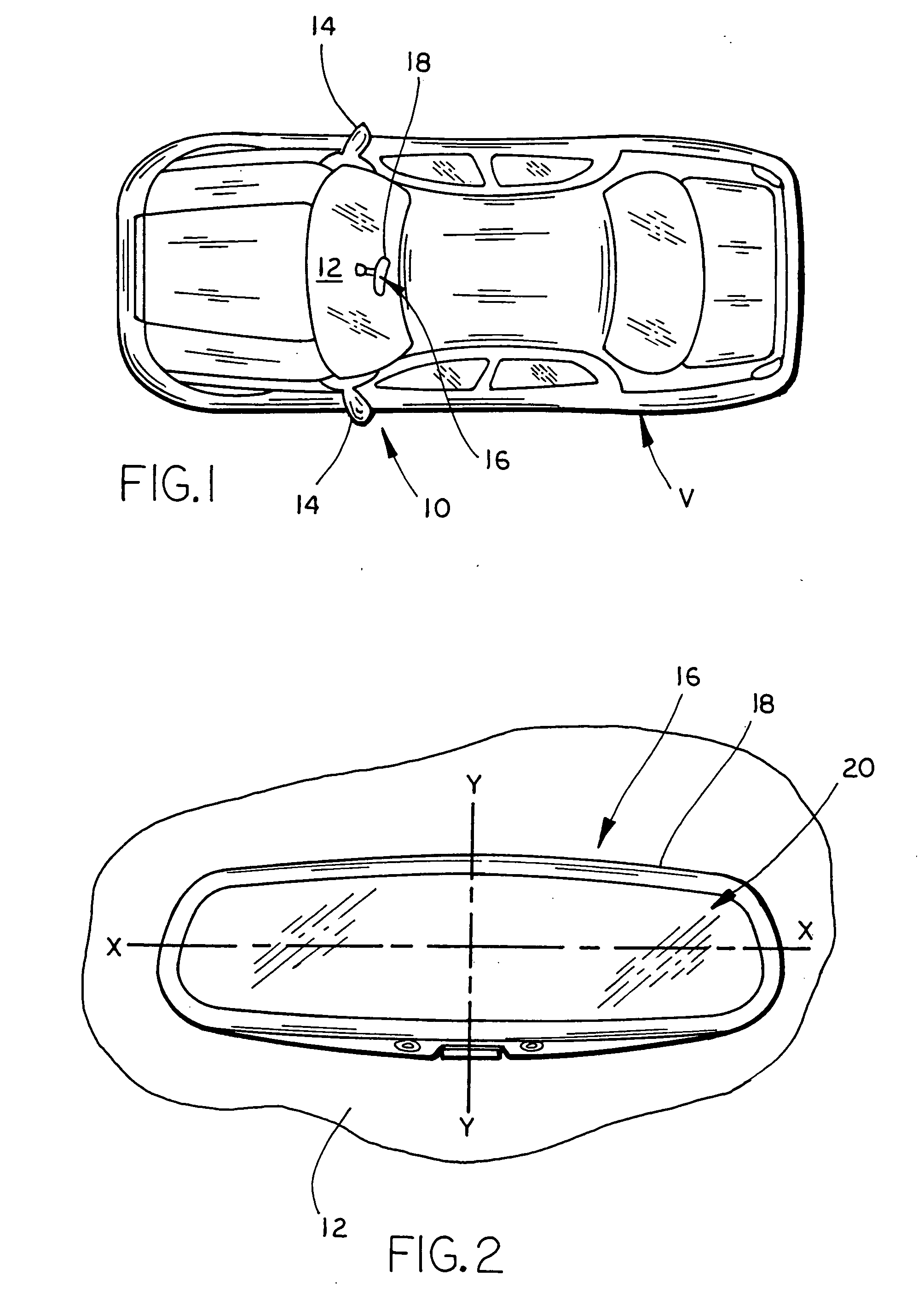

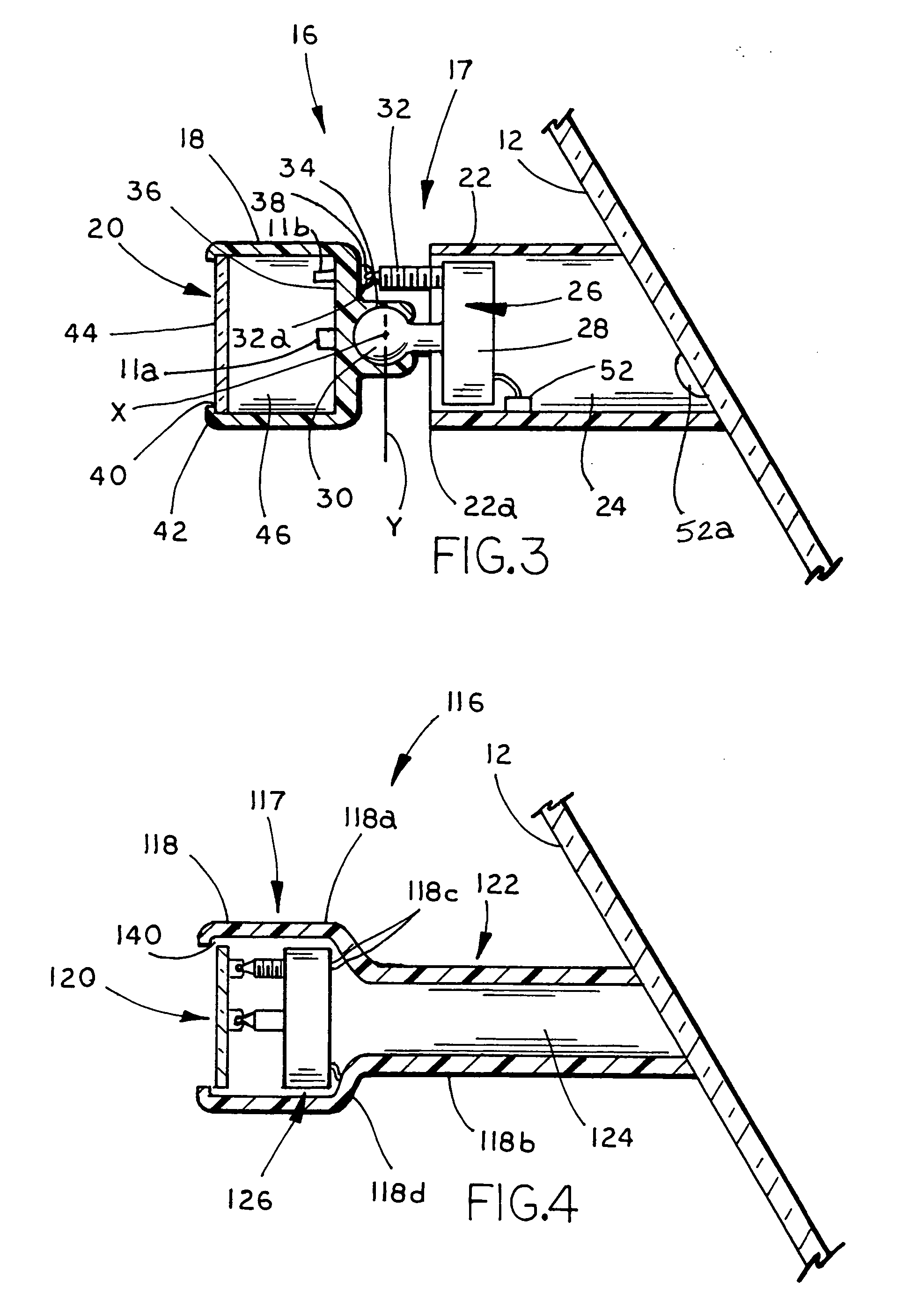

[0031] Referring to FIG. 1, the numeral 10 generally designates a memory mirror system of the present invention for a vehicle V. Memory mirror system 10 includes passenger-side and driver-side exterior sideview mirror assemblies 14 and an interior rearview mirror assembly 16, which is mounted to a windshield 12 of vehicle V. In the present invention, interior rearview mirror assembly 16 is adapted to provide an interior rearview mirror assembly for memory mirror system 10, as noted above, which exhibits enhanced vibration characteristics and, further, provides increased storage capacity for various devices or accessories which may be incorporated into assembly 16, as will be more fully described below.

[0032] While reference is made to exterior rearview mirror assemblies 14, the focus of this present application is on interior rearview mirror assembly 16; therefore, further details of the exterior rearview mirror assemblies 14 are not provided herein. Examples of suitable exterior r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com