Conductive adhesive and piezoelectric device using it

A technology for conductive adhesives and piezoelectric components, which is applied in conductive adhesives, non-polymer adhesive additives, electrical components, etc., and can solve elastic deformation, large subsidence of SAW components, and inability to obtain a joint state, etc. problem to ensure wire bonding and reduce sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

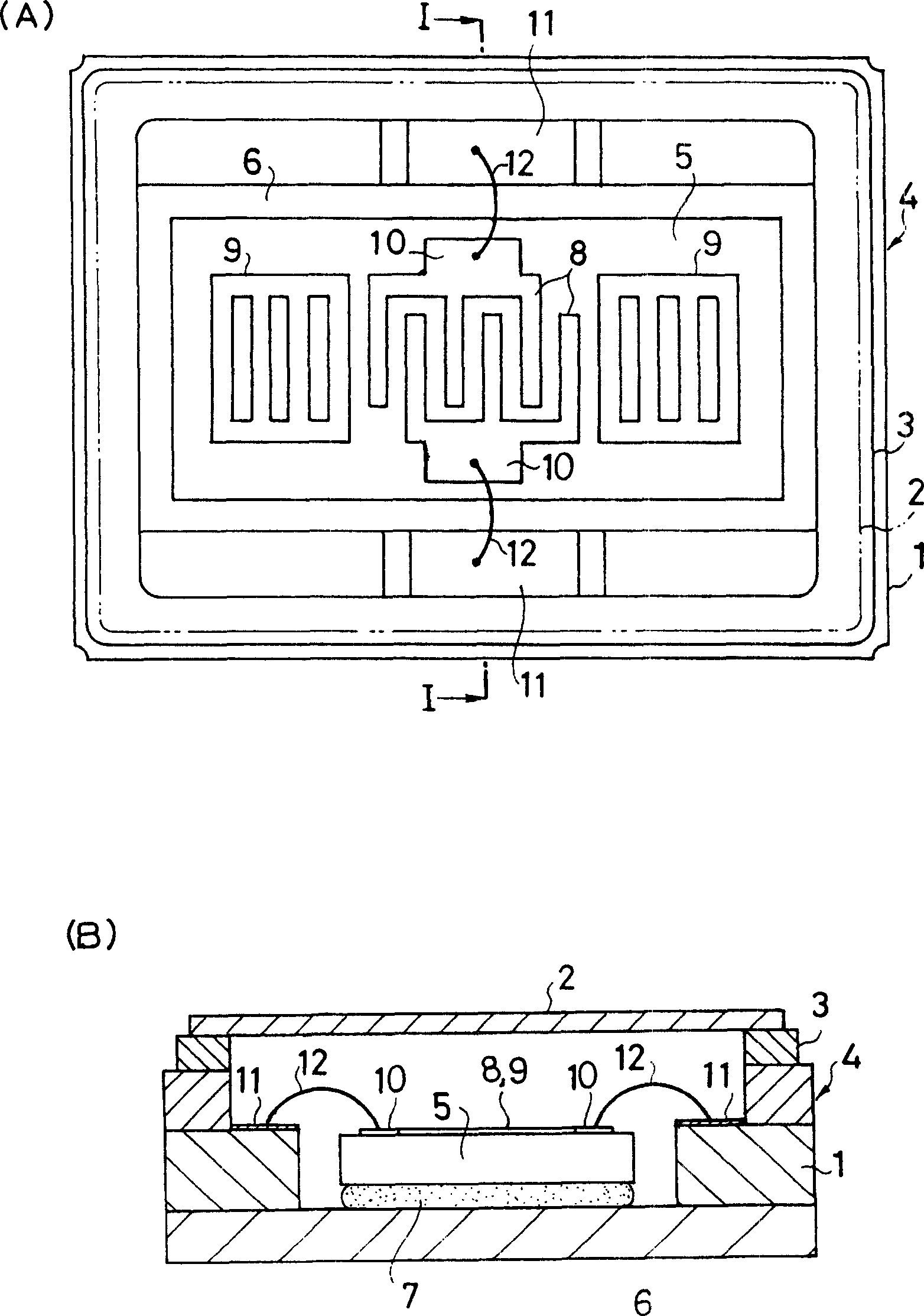

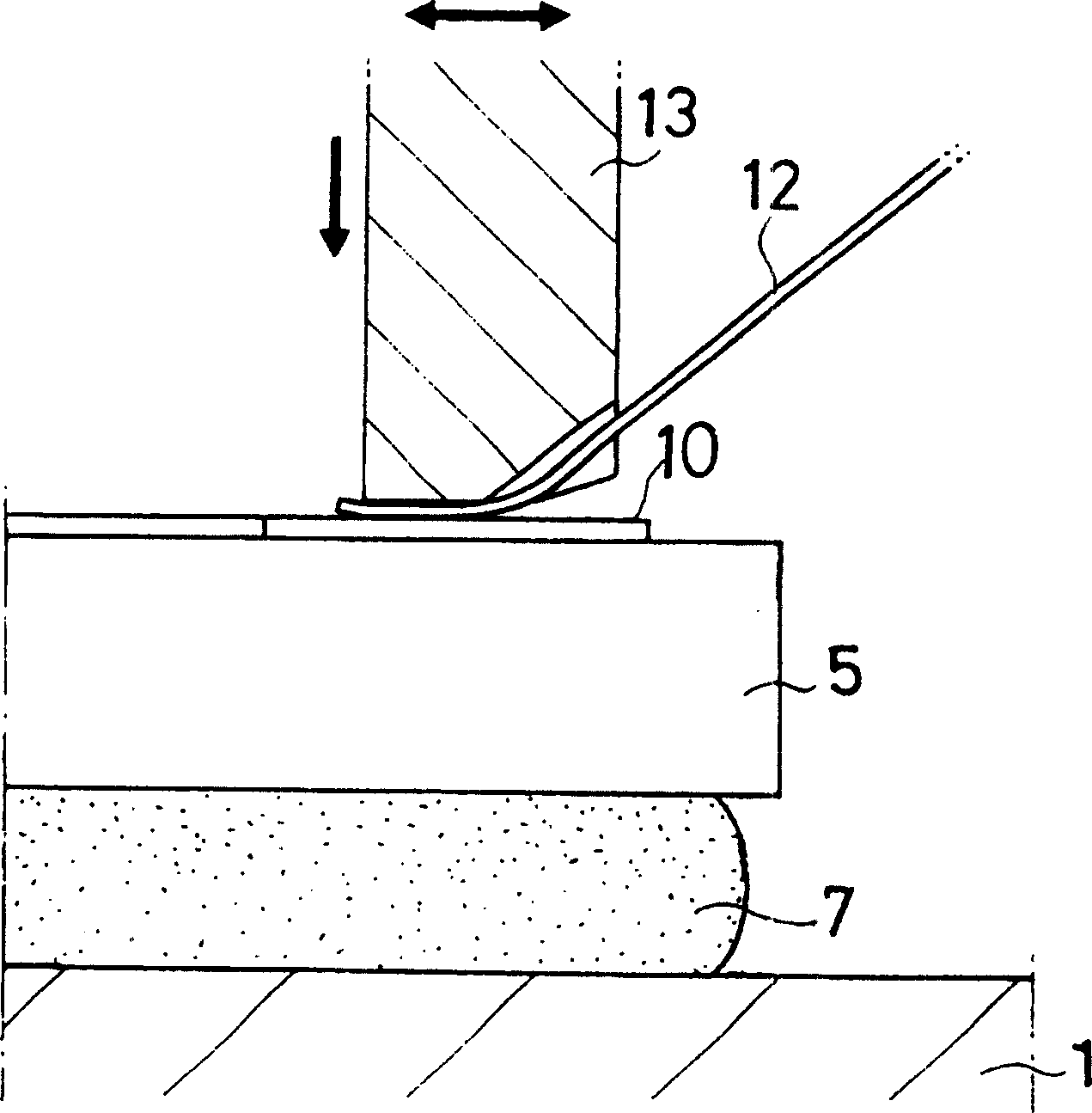

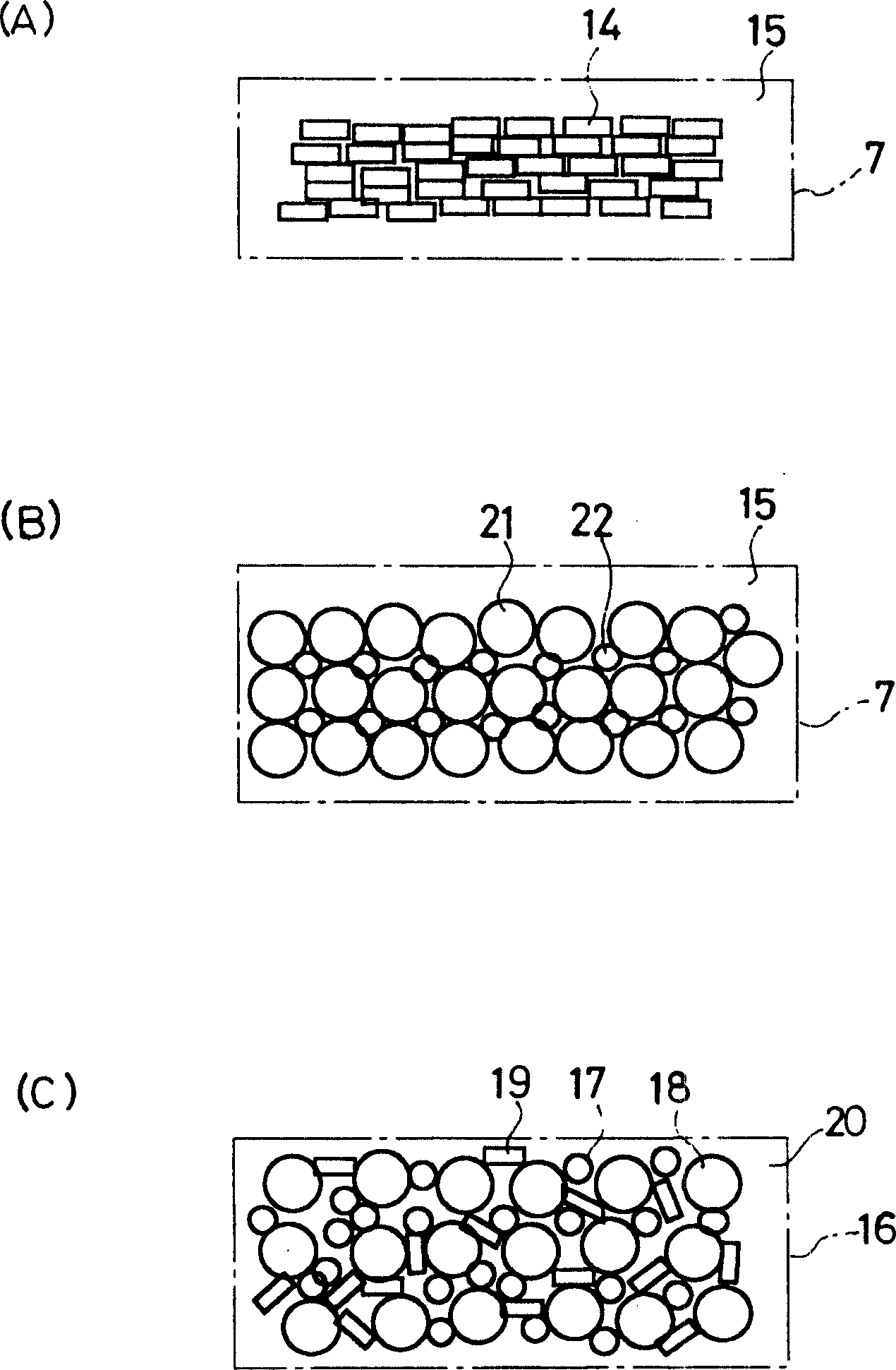

[0045] Use respectively with image 3 (A) The conductive adhesive of the first embodiment of the present invention related to the above. image 3 (B) The Conductive Adhesive of the Second Example Related to the Above A SAW resonator in which a SAW element was bonded and fixed was produced (this Example 2). When bonding SAW components to the base mounting surface, the die fixing conditions, that is, the pressing force is 20+ / -15g / cm 2 , The hardening conditions of the conductive adhesive are: the present embodiment 1 is 180 ° C × 1 hour of N2 drying, and the present embodiment 2 is 280 ° C × 3 hours of vacuum drying. An Al / Si1% bonding wire with a diameter of 40 μm was used as the bonding wire, and wedge welding was performed using a commercially available fully automatic ultrasonic wedge welding machine under the conditions of a processing time of 20 ms, an ultrasonic output of 150 W, and an applied force of 50 g. As a comparative example, the structure is the same as that o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com