An aluminum vehicle body noise transfer path optimization method based on plate sound pressure contribution

A technology for noise transfer and path optimization, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems affecting vehicle driving safety, increase driver and passenger fatigue, improve noise transfer characteristics, and shorten R&D. cycle, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

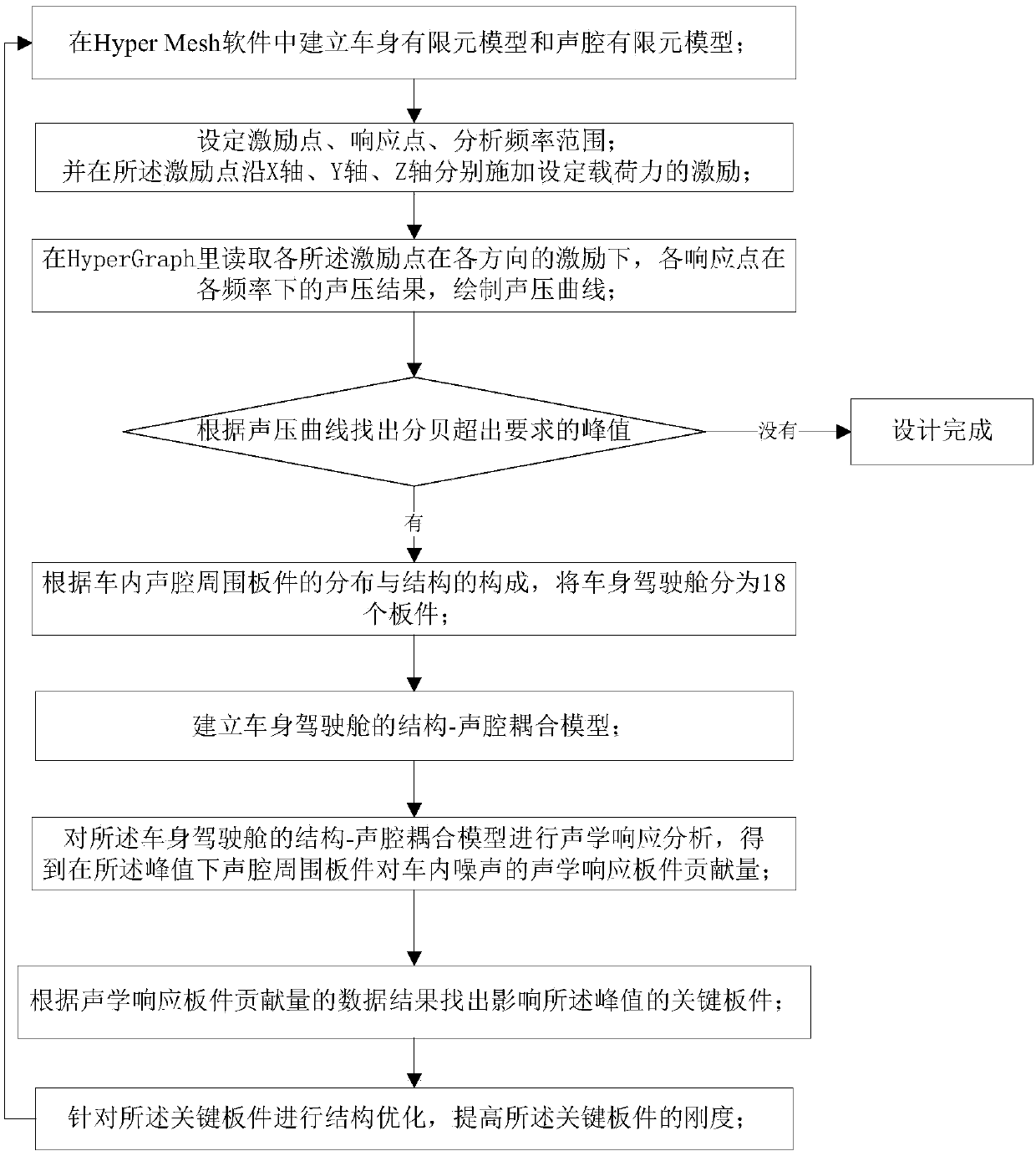

[0030] Please refer to figure 1 , the present embodiment is a method for optimizing the noise transmission path of an aluminum body based on the sound pressure contribution of the panel, which includes the following steps:

[0031] (1) Design input: The finite element model of the vehicle body and the finite element model of the acoustic cavity are established in the Hyper Mesh software.

[0032] (2) Boundary condition setting: it includes setting the excitation point and response point, setting the analysis frequency range; and respectively applying the set load force F (such as 1N) along the X axis, Y axis, and Z axis at the excitation point The excitation; the analysis frequency range is 20-200Hz.

[0033] in,

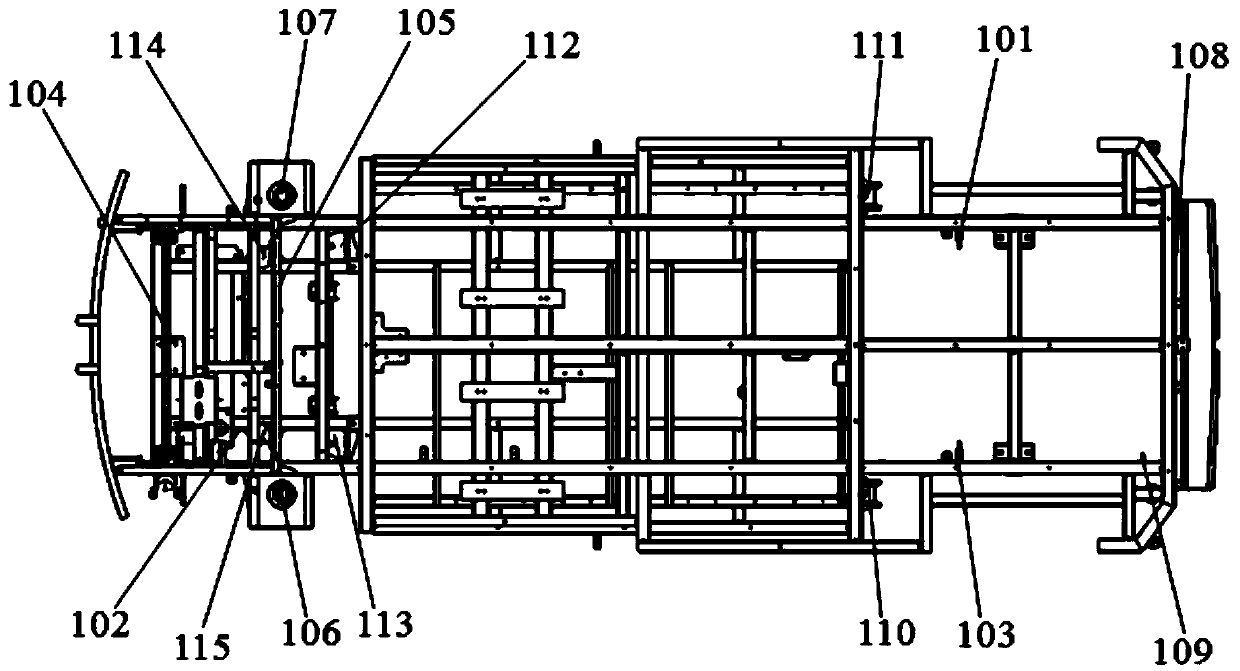

[0034] Please refer to figure 2 , the excitation points include: left rear shock absorber mounting point 101, rear suspension mounting point 102, left rear shock absorber mounting point 103, front suspension mounting point 104, left suspension mounting point 105...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com