Easy-to-assemble floating track bed precast slab and application thereof

A floating track bed and prefabricated board technology, which is applied in the field of rail transit, can solve the problems of extremely high processing precision of prefabricated short boards, accidental damage, and influence on popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

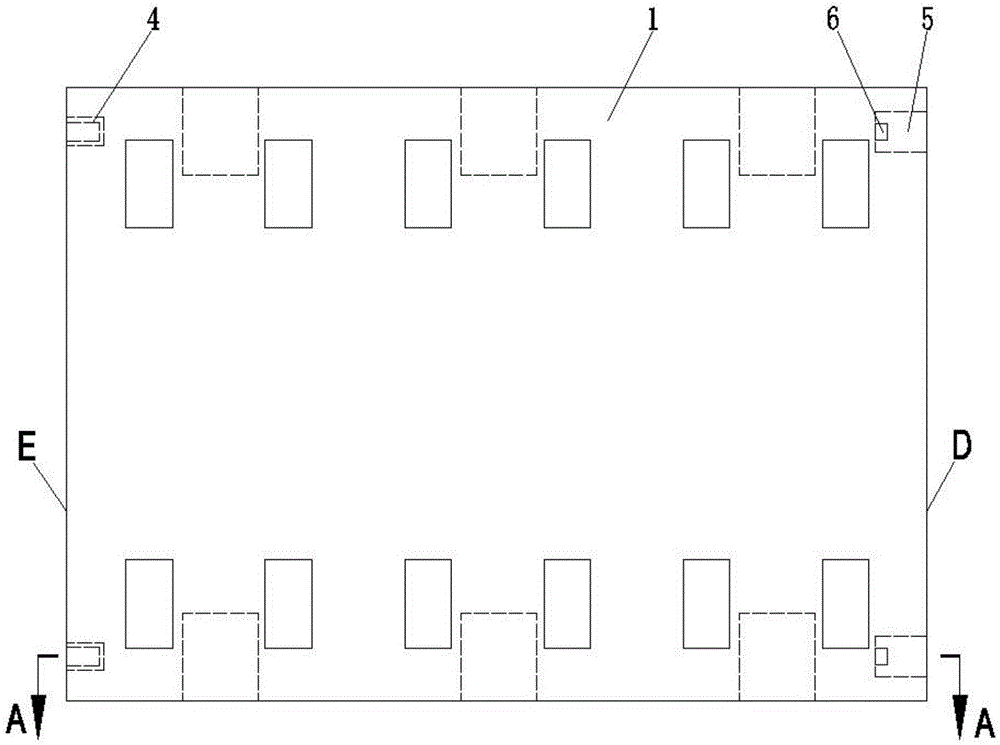

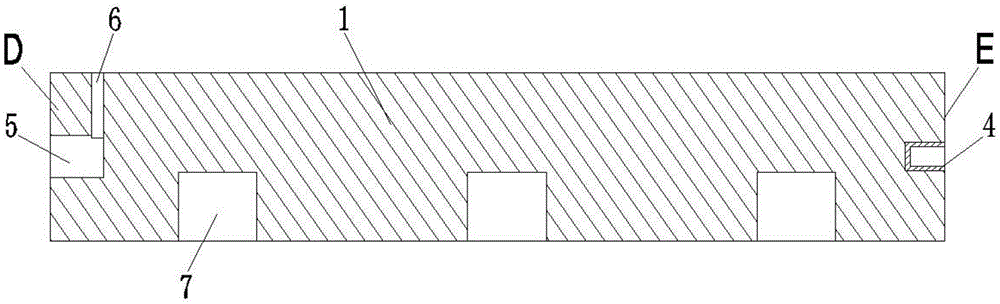

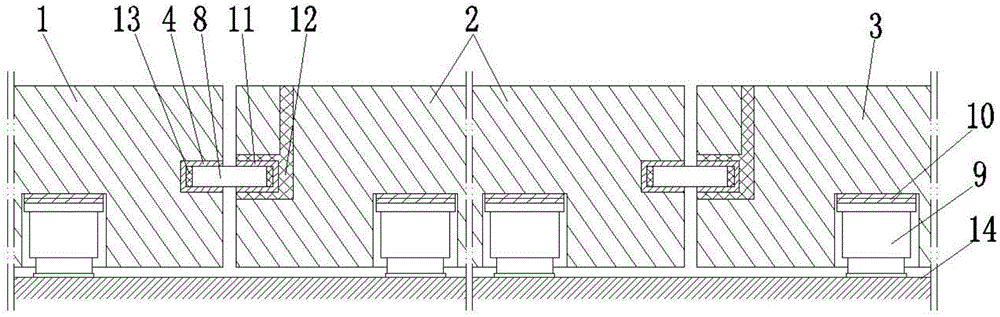

[0059] like figure 1 and figure 2 The easy-to-assemble floating ballast bed prefabricated slab of the present invention as shown includes a prefabricated slab body 1, which is provided with a reserved space 7 for installation that cooperates with an elastic vibration isolation device, and the middle part of the connecting end E of one side of the prefabricated slab body 1 The positioning guide sleeve 4 is fixedly arranged, and the middle part of the connecting end D on the other side is provided with a docking assembly hole 5 correspondingly. Two positioning guide sleeves 4 are symmetrically arranged on both sides of the connecting end E, and the number of the docking assembly holes 5 is the same as that of the positioning guide sleeves 4. The prefabricated plate body 1 is also provided with a grouting channel 6, and one end of the grouting channel 6 is connected to the docking assembly hole 5. The bottom is connected, and the other end is opened on the upper surface of the ...

Embodiment 2

[0073] like Figure 4 and Figure 5 As shown, the present invention is easy to assemble the prefabricated slab of the floating ballast bed, and figure 1 and figure 2 The difference between the easy-to-assemble floating ballast bed prefabricated panels shown is that the prefabricated panel body 1 is provided with a coupling sleeve 17 that cooperates with the elastic vibration isolation device; in addition, three positioning guide sleeves 4 are provided in the middle of the connecting end E, one of which is positioned The guide sleeve 4 is arranged at the center position of the transverse end surface of the connection end E, and the other two positioning guide sleeves 4 are arranged symmetrically on both sides of the connection end E, and the docking assembly holes 5 correspond to the number and position of the positioning guide sleeve 4; in addition, In order to facilitate observation and cleaning of sundries under the prefabricated panel body, an observation port 15 is also...

Embodiment 3

[0092] like Figure 7 and Figure 8 As shown, the present invention is easy to assemble the prefabricated slab of the floating ballast bed, and Figure 4 and Figure 5 The difference between the easy-to-assemble floating ballast bed prefabricated panels shown is that the observation port 15 is arranged at the connection ends on both sides of the prefabricated panel body 1; in addition, the prefabricated panel body 1 is also provided with an exhaust channel 16, and one end of the exhaust channel 16 is connected to the The docking assembly hole 5 is connected, and the other end is opened on the upper surface of the prefabricated panel body 1; in addition, an anchoring device 18 is fixedly installed on the outer surface of the positioning guide sleeve 4, and the anchoring device 18 is formed by coiling the positioning guide sleeve 4 with threaded steel bars. Anchor ring constitutes.

[0093] like Figure 9 application shown Figure 7 and Figure 8 The difference between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com