Cement-concrete paving and leveling device

A cement concrete and leveling device technology, which is applied in roads, road repairs, roads, etc., to achieve the effects of prolonging service life, improving economic benefits, and reducing maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

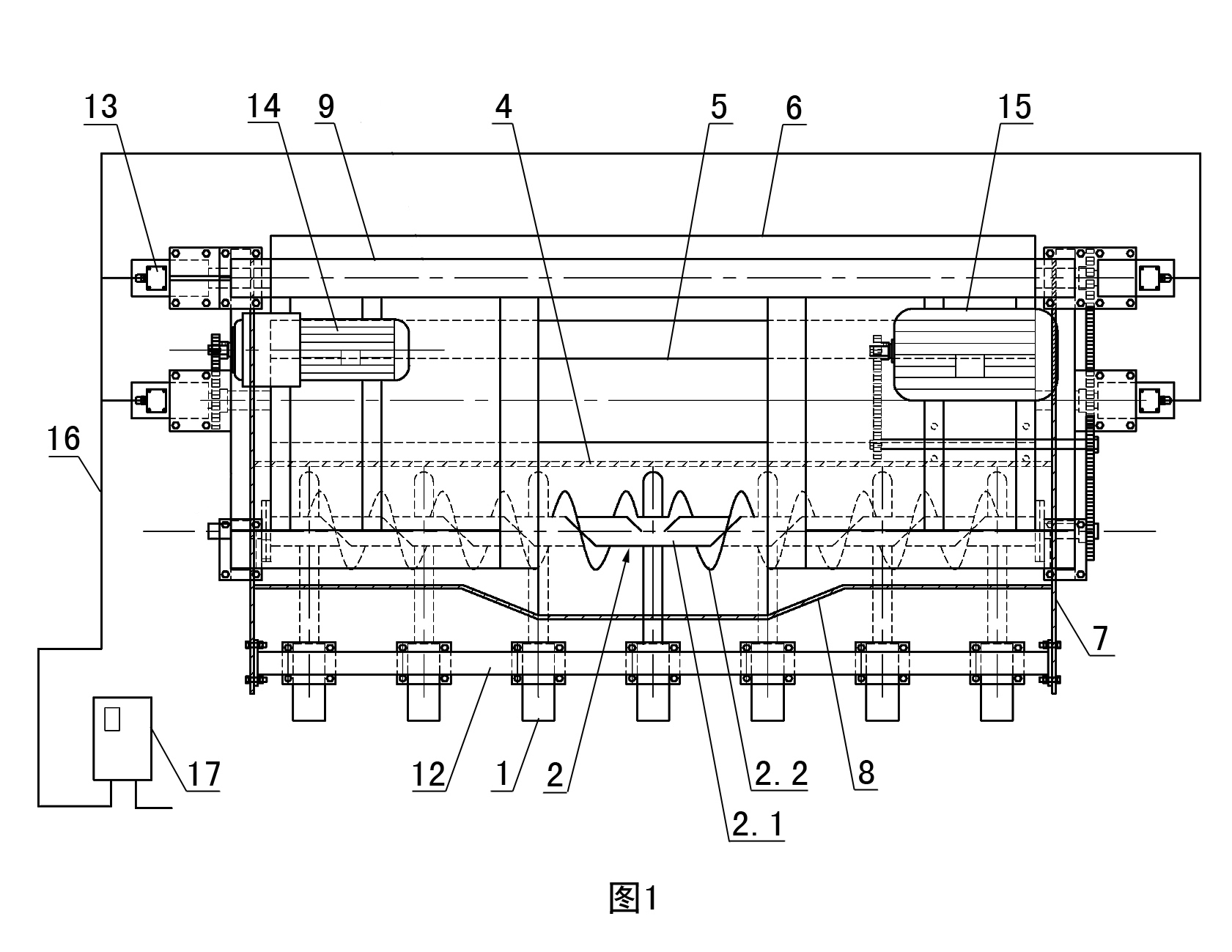

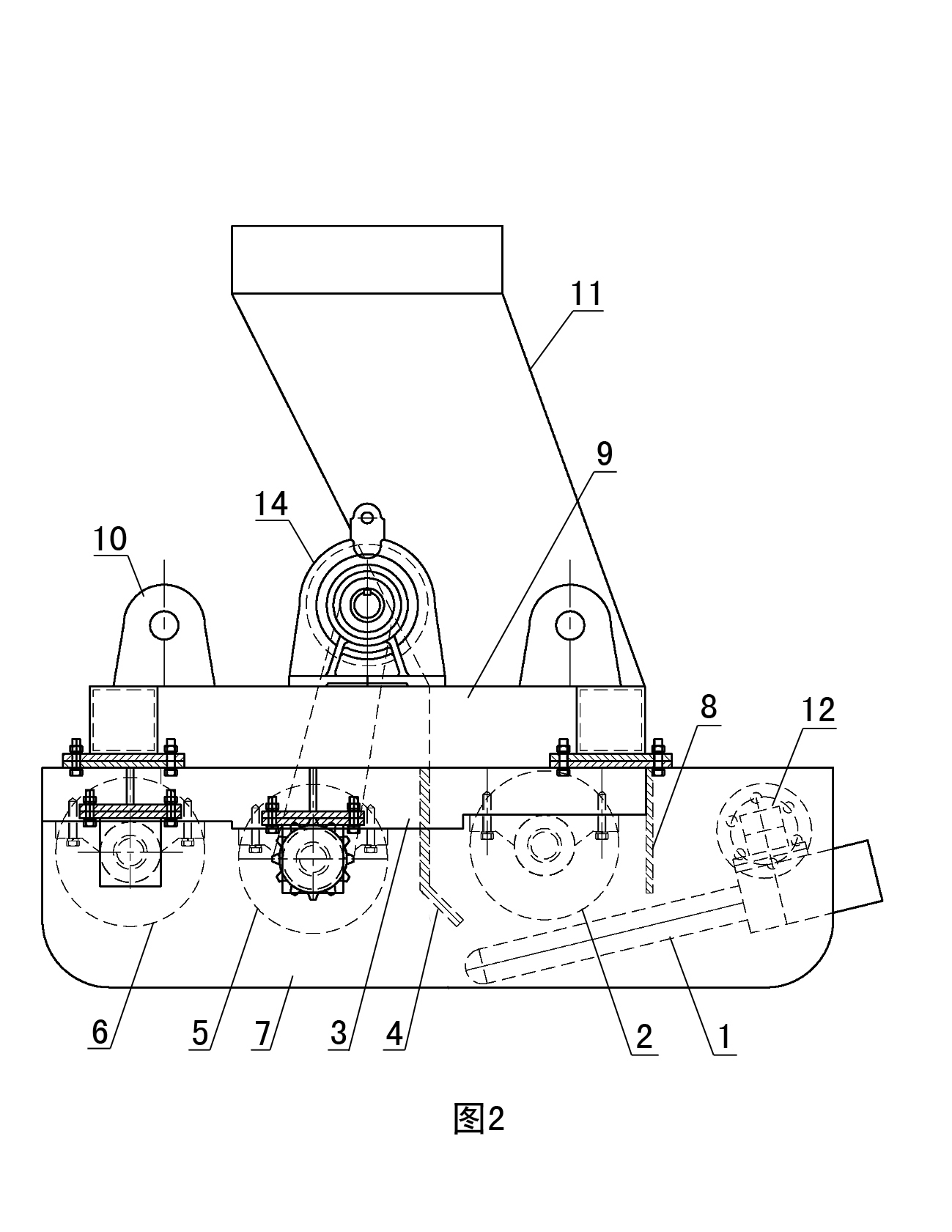

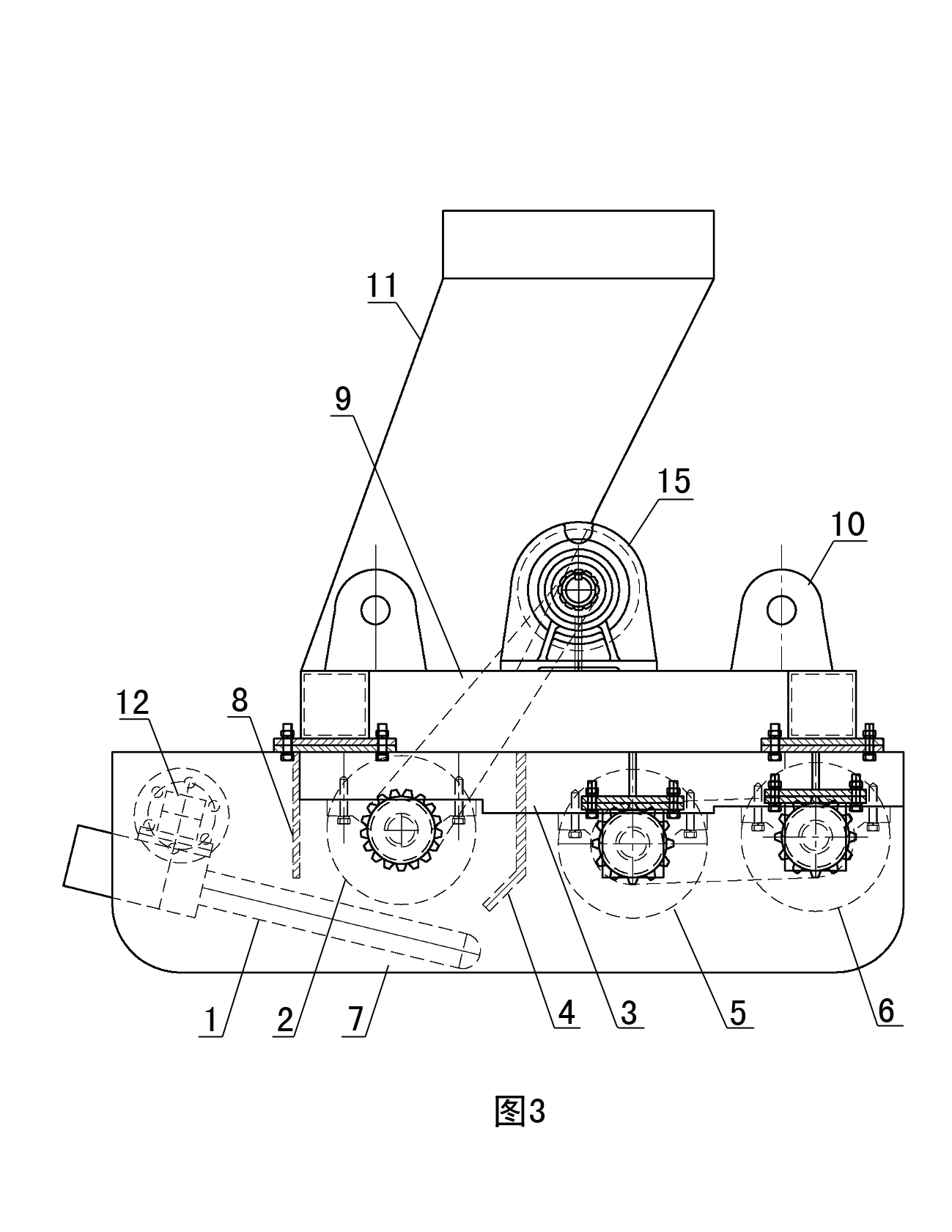

[0028] Examples see Figure 1-3 As shown, this cement concrete paving and leveling device includes a working frame and a vibrating device connected to the working frame from front to back, a distributing device and a leveling and rolling device, wherein the vibrating device consists of a vibrating device Rod mounting bracket 12 is formed with a row of vibrating rods 1 connected to the vibrating rod mounting bracket. In the present embodiment, there are seven vibrating rods. Fixed on the working frame, the material distribution screw motor 15 that drives the material distribution screw 2 to rotate, in the present embodiment, the material distribution screw motor 15 drives the material distribution screw 2 through the chain transmission structure, and the leveling and rolling device is connected by rotation. The front vibrating rolling roller 5, the rear vibrating rolling roller 6 and the power source fixed on the working frame to drive the front vibrating rolling roller 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com