Tomato harvesting and separating device and tomato harvester using same

A separation device and harvester technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low vibration frequency, low reliability, complex structure, etc., and achieve high vibration frequency, reliable operation, and small power loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

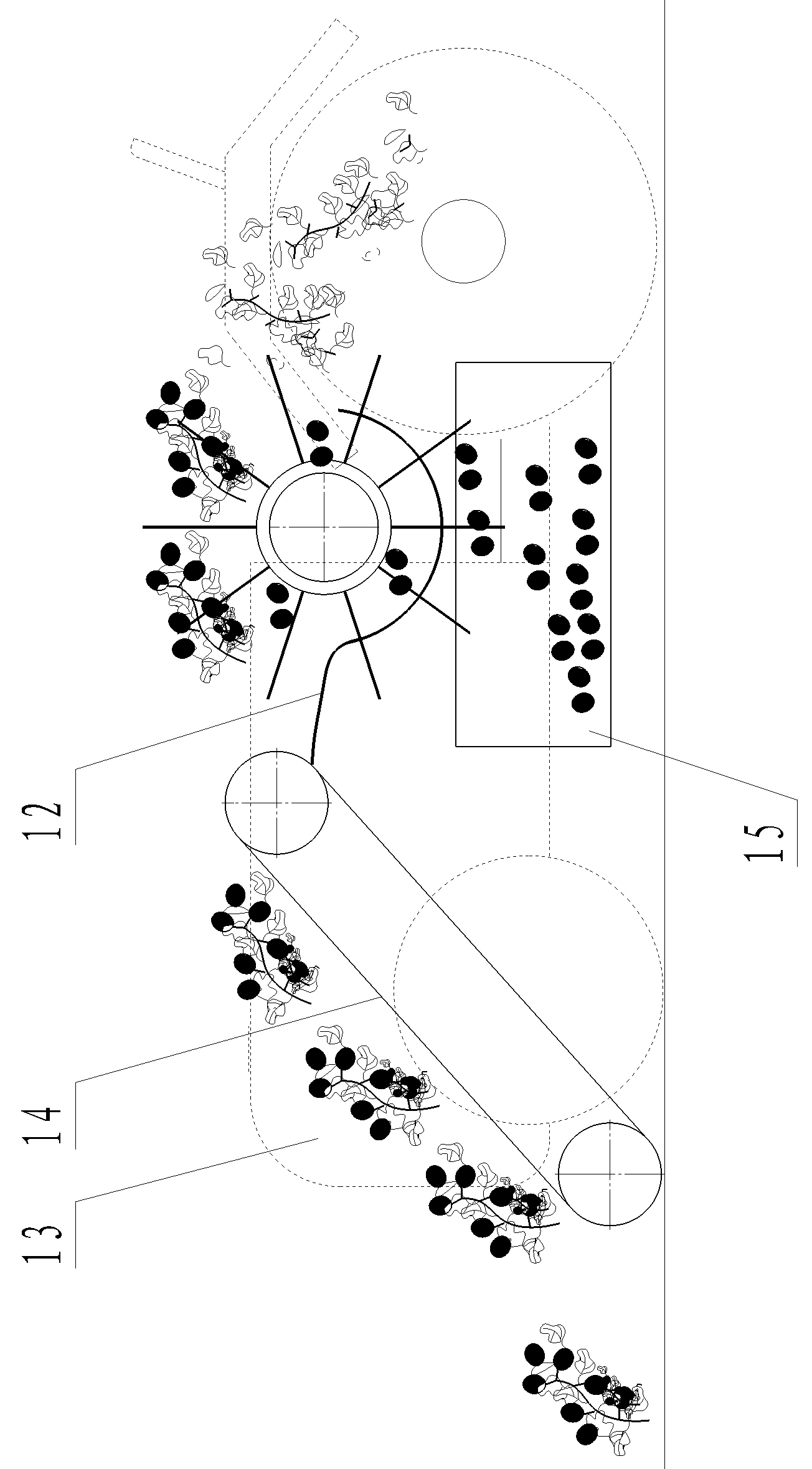

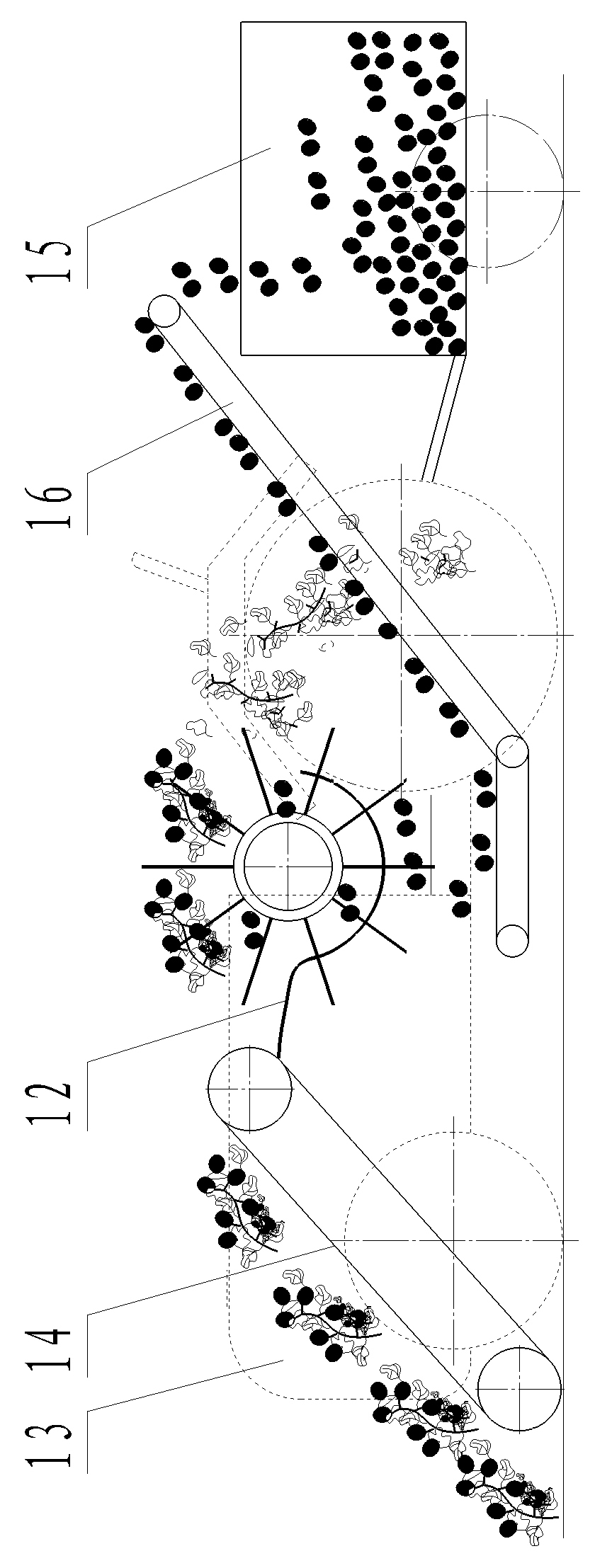

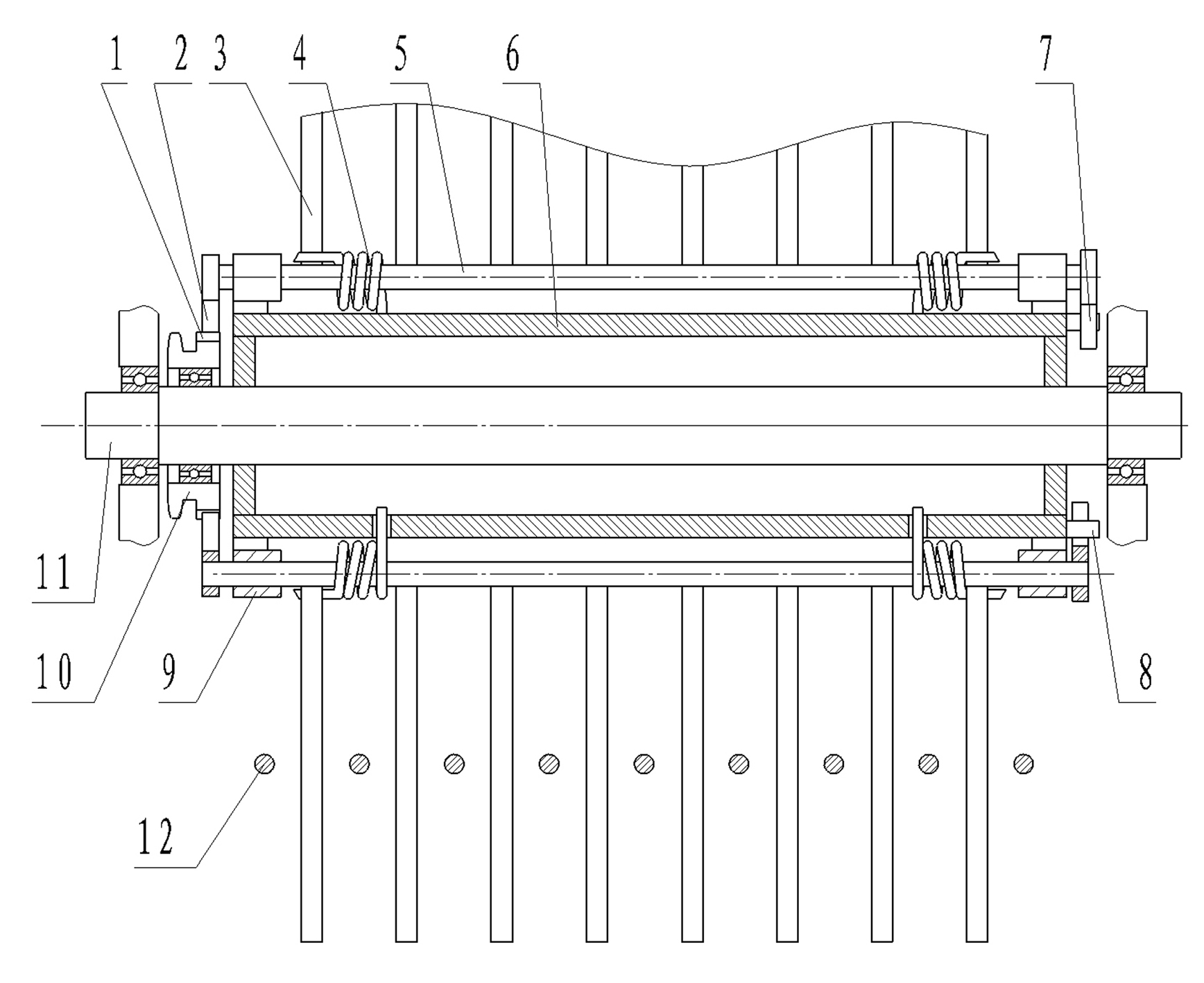

[0021] Embodiment 1: refer to Figure 1~Figure 3 , is a schematic structural diagram of the harvesting and separating device in Example 1 of the present invention. Comprising a grid screen 12 and a spring tooth cylinder 6, a spring tooth bar 5 is axially arranged on the circle of the spring tooth cylinder 6, and the spring teeth 3 arranged in a finger shape on the spring tooth bar 5 and the spring teeth 3 are arranged around the circle of the spring tooth cylinder 6 The top is radially radial, and the spring tooth rod 5 is connected to the spring tooth roller 6 through the bearing seat 9 and can rotate in the bearing seat 9. The spring tooth bar 5 is provided with a return spring 4 and a swing rod 2, and the return The spring 4 is a torsion spring, which is arranged on the spring tooth bar 5, and the swing bar 2 is arranged on one end of the spring tooth bar 5, and the end of the spring tooth roller 6 corresponding to the swing bar 2 is provided with a Elastic tooth cylinder ...

Embodiment 2

[0023] Embodiment 2: refer to Figure 4 , is a schematic structural diagram of the harvesting and separating device in Example 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the tooth-shaped protrusions 1 on one circumference of the vibrating cam 10 are arc-shaped protrusions.

Embodiment 3

[0024] Embodiment 3: refer to Figure 5 , is a schematic structural diagram of the harvesting and separating device in Example 5 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the return spring 4 is a tension spring, one end of the tension spring is connected to the limit rod 7 at the end of the spring tooth rod 5, and the other end is connected to the upper limit of the spring tooth roller 6. The gear bar 8 is connected. Extension spring among the present embodiment also can be replaced by compression spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com