Vibrating lycium chinensis harvesting vehicle

A vibratory, goji berry technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problem that the goji berry harvesting device cannot meet the needs of actual use, achieve low damage rate, improve harvesting efficiency, and clean high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

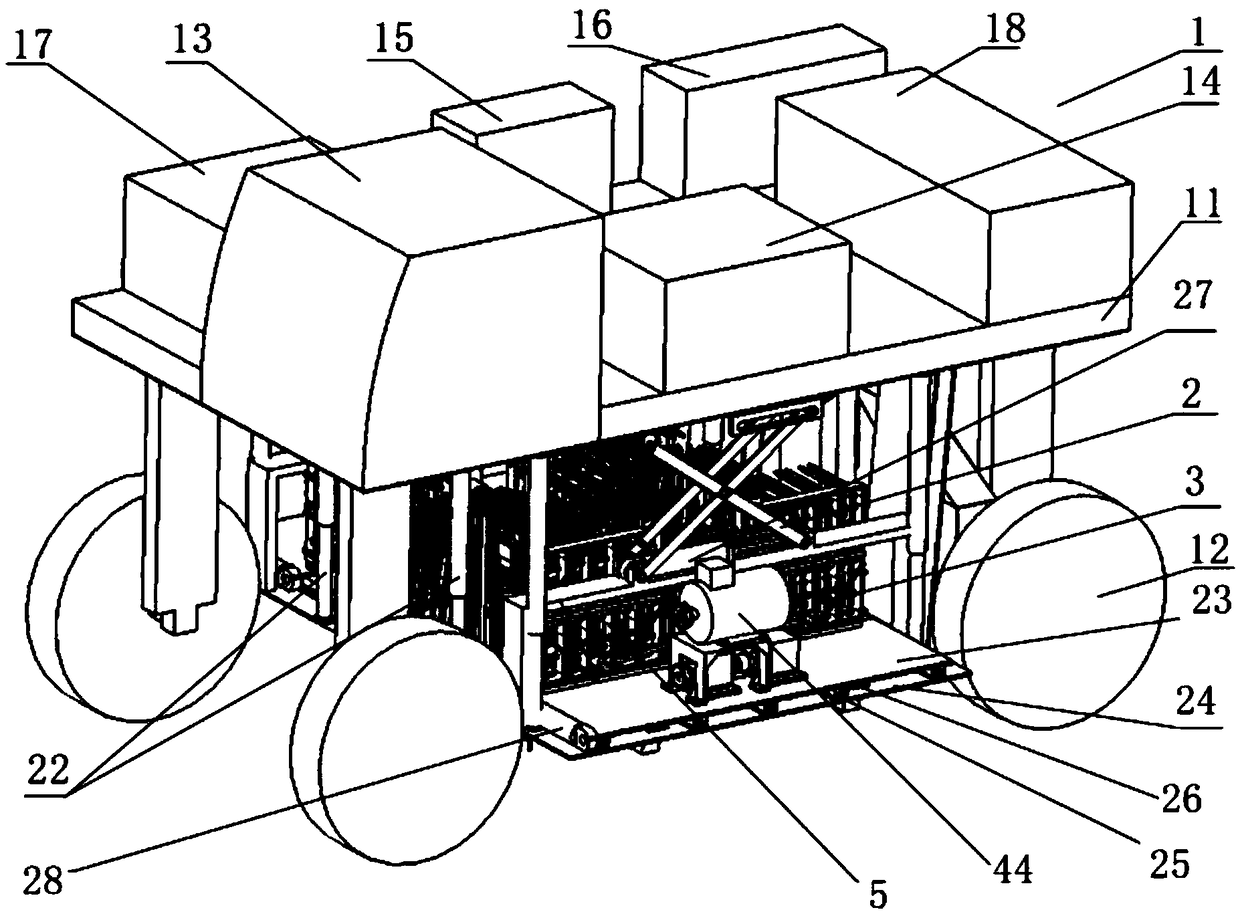

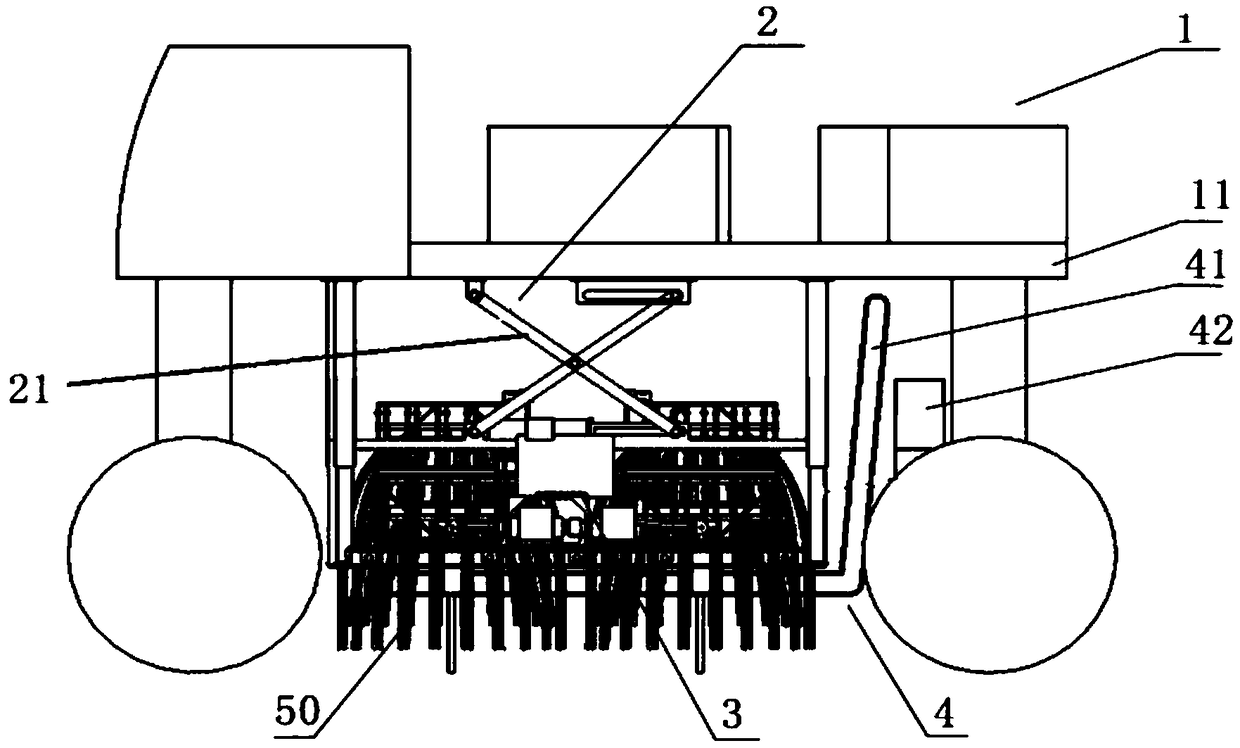

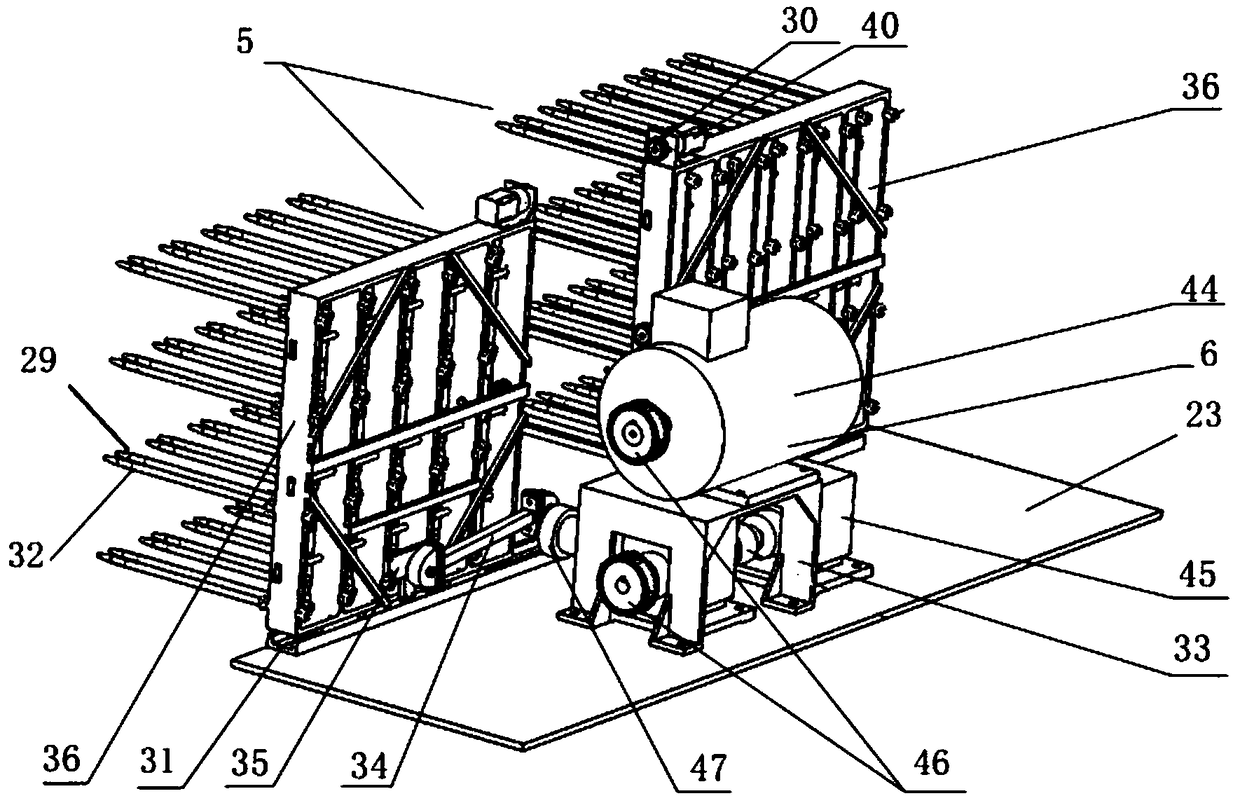

[0031] Such as figure 1 and figure 2 As shown, a kind of vibrating wolfberry harvesting vehicle of the present invention comprises a high clearance car body 1, the high clearance car body 1 is a traditional clearance car body structure, the chassis 11 of the high clearance car body 1 and The vertical distance of the ground is higher than the height of the Lycium barbarum plant 50, so that the tires 12 of the high clearance car body 1 avoid crushing the plants when harvesting Lycium barbarum (the Lycium barbarum plant 50 is located between the tires 12 on both sides of the high clearance car body 1 ), and the chassis 11 can be straddled on the Lycium barbarum plant 50, which is convenient for harvesting operations. According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com