Artificial stone production system

A production system, artificial stone technology, applied in the field of machinery, can solve the problems of artificial stone water absorption, bending strength deviation, uneven force on the mold, high labor intensity of workers, etc., to increase the total mixing time, reduce labor costs, avoid The effect of unnecessary loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

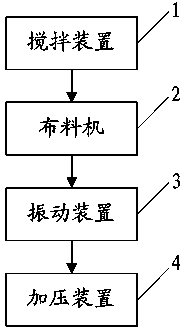

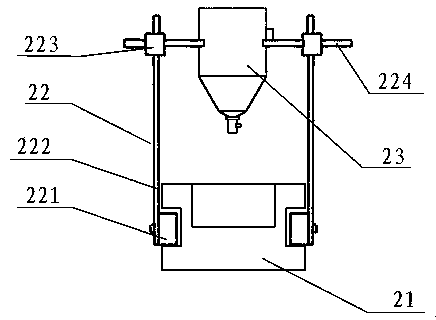

[0065] combine figure 1 , The present invention provides an artificial stone production system including a stirring device 1 , a distributing machine 2 , a vibrating device 3 , and a pressurizing device 4 . The stirring device 1 , the distributing machine 2 , the vibrating device 3 and the pressurizing device 4 are sequentially connected through a transmission device.

[0066] The invention is used in the field of artificial stone production, and can complete production tasks according to preset production tasks, especially can prepare high-grade, high-fidelity artificial stone, and has the characteristics of high production efficiency and high product qualification rate.

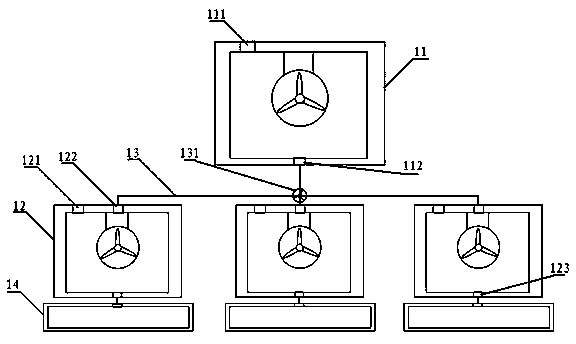

[0067] figure 2 It is a structural schematic diagram of the stirring device in the artif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com