Apparatus for generating fluctuating counter pressure in air inlet test

A technology for generating devices and air intakes, applied in aerodynamic tests, measuring devices, jet engine testing, etc., can solve problems such as inability to simulate real conditions, and achieve the effect of low motor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

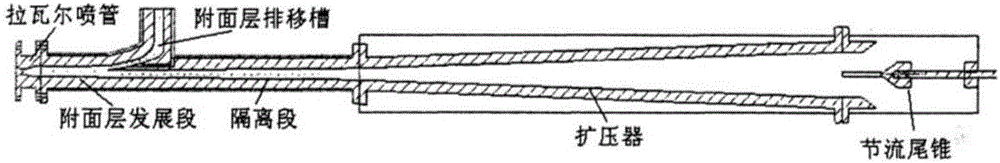

Method used

Image

Examples

Embodiment Construction

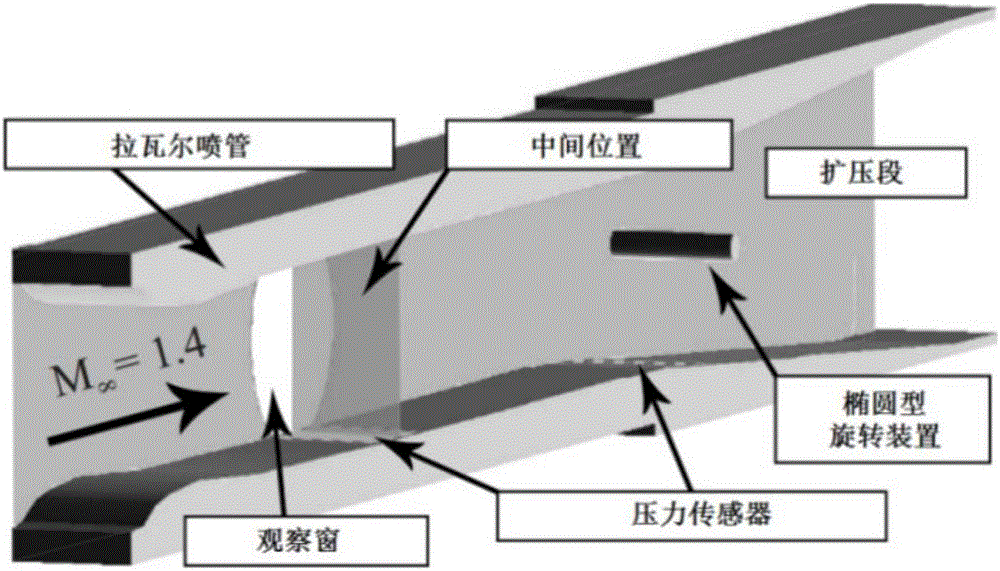

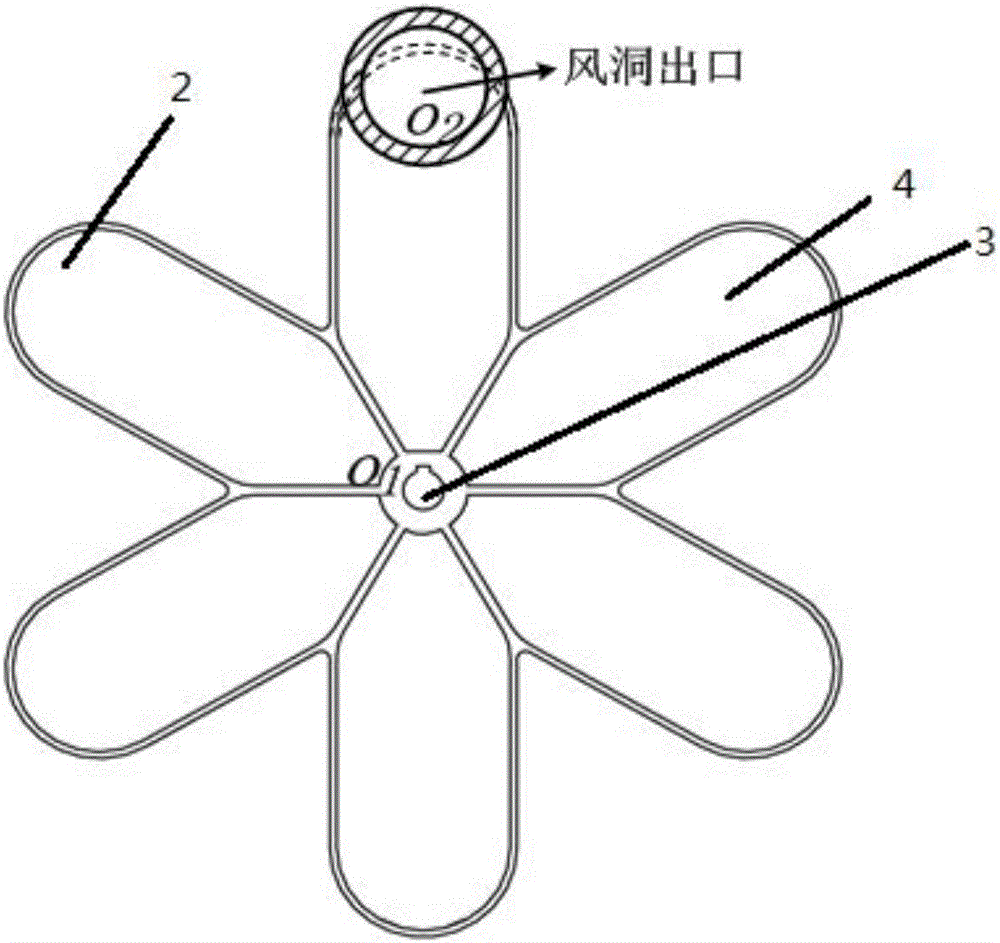

[0033] The present invention will be further described below with reference to the drawings and specific embodiments.

[0034] Reference image 3 with Figure 4 In this embodiment, an air inlet test pulsation back pressure generating device includes a throttle rotary vane 1 installed outside the outlet of the wind tunnel and a driving mechanism for driving the throttle rotary vane 1 to rotate. The throttle rotary vane 1 includes 2 For the rotary vanes 2 above, the throttle rotary vane 1 rotates under the drive of the driving mechanism. During the rotation, each rotary vane 2 can block a certain area of the wind tunnel outlet in turn to generate throttling. The driving mechanism of the present invention includes a frequency conversion motor and a frequency converter. The central shaft sleeve of the throttle rotary vane is connected with the drive shaft of the frequency conversion motor. The frequency conversion motor is connected with a frequency converter. The rotation speed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com