Internal combustion type mechanical and electric energy output method and apparatus therefor

A technology of energy output and mechanical energy, applied in the field of internal combustion mechanical and electric dual energy output method and its device, can solve problems such as unreasonable matching, complex system, uncoordinated work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

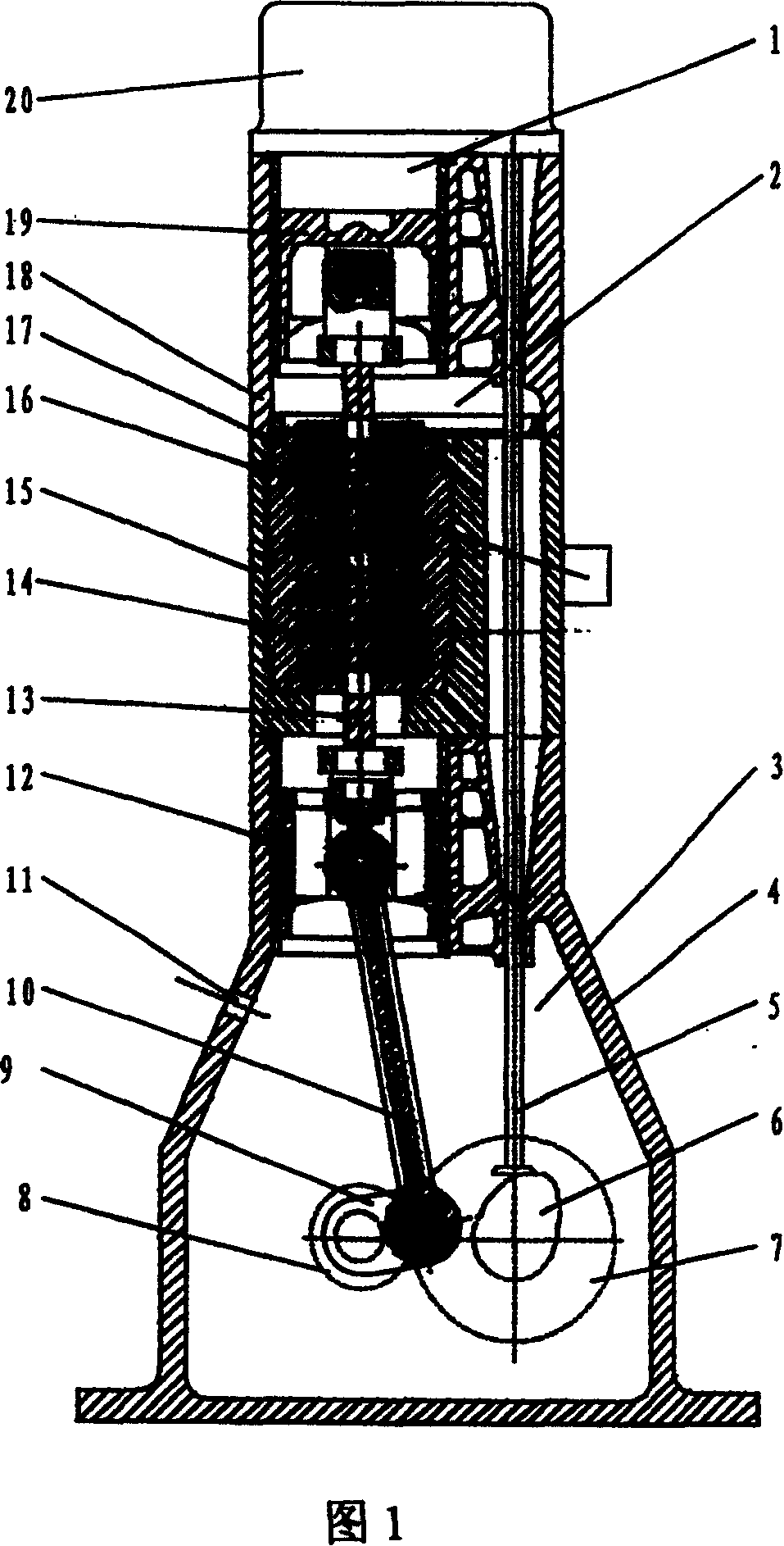

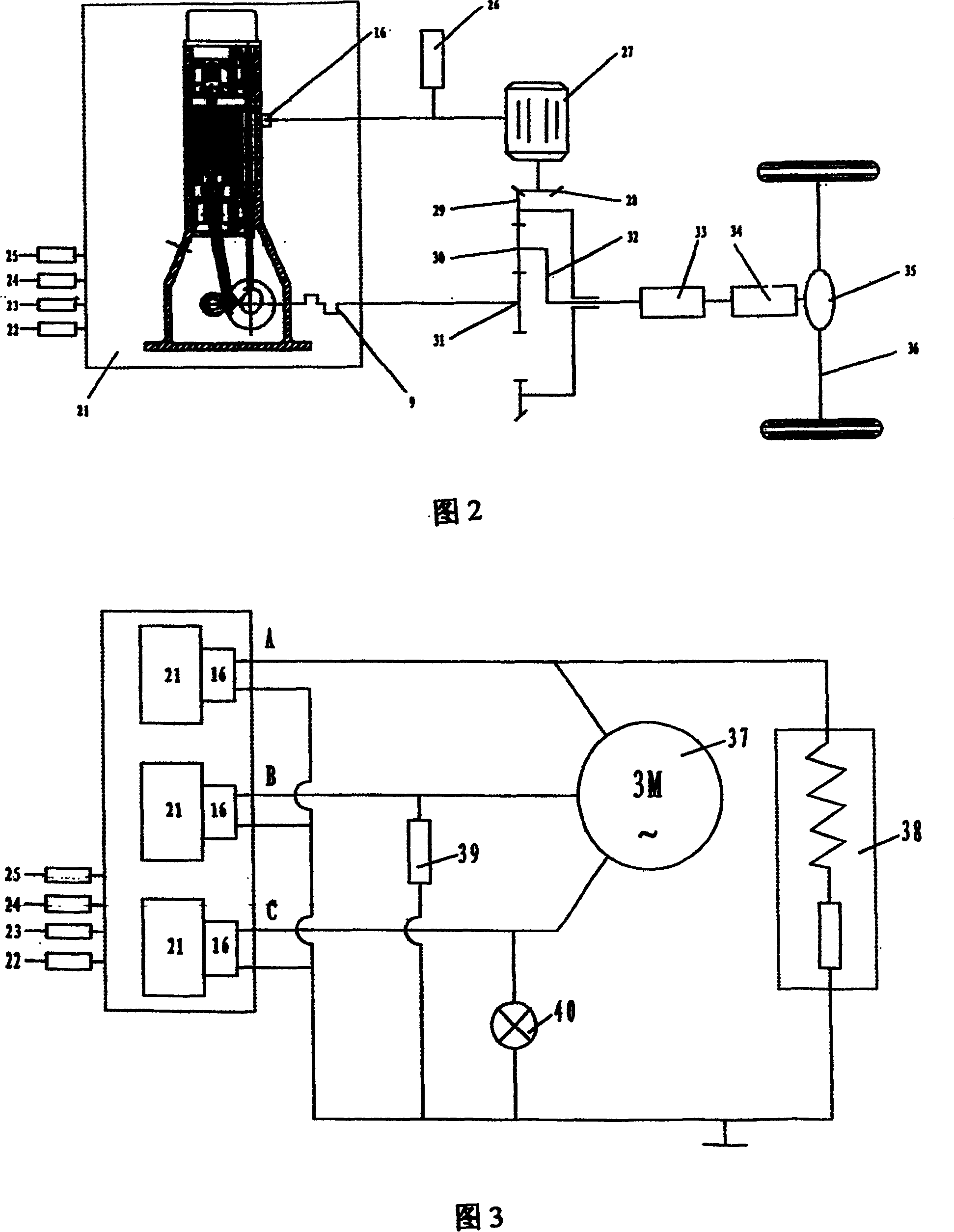

[0026] Example 1: Vehicle Machinery-Electric Hybrid Power Transmission System

[0027] On the energy conversion device 21 involved in the present invention, a fuel supply system 22, a cooling system 23, a lubricating system 24, and an ignition (starting) system 25 are equipped with a conventional technical method, and the power output terminal 16 of the device 21 of the present invention is connected in parallel with a storage battery 26 Constitute the power supply of the generator / motor 27, the mechanical power output end of the generator / motor 27 forms a gear pair through the motor gear 28 and the ring gear 29, and the crankshaft-flywheel assembly 9 is phased with the sun gear 31 of the energy converging device according to the prior art process Connected, the ring gear 29, the sun gear 31, the planetary gear, and the planetary carrier 32 form an energy confluence device, which confluences the mechanical power from the generator / motor 27 and the crankshaft-flywheel assembly 9...

Embodiment 2

[0028] Example 2: Hybrid Power Supply System for Power and Lighting

[0029] On the energy conversion device 21 involved in the present invention, adopt conventional technical method to equip fuel supply system 22, cooling system 23, lubricating system 24, ignition (starting) system 25, control energy conversion device 21 three groups of cylinders involved in the present invention The fuel supply sequence is such that the energy conversion device 21 involved in the present invention forms a three-phase voltage on the power output junction box 16, that is, phase A, phase B, and phase C, which is realized by connecting the three-phase AC voltage according to the wiring requirements of the three-phase asynchronous motor 37 Three-phase power supply; connecting inductive load 38 at junction box 16A to realize single-phase power supply; connecting other resistive loads 39 at junction box 16B to realize single-phase power supply; connecting lighting lamp 40 at junction box 16C to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com