Piston engine having magnetic piston bearing

A piston engine and piston technology, applied in free piston engines, bearings, magnetic bearings, etc., can solve the problems of high maintenance costs and high environmental load, and achieve the effects of preventing friction, economical production, and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

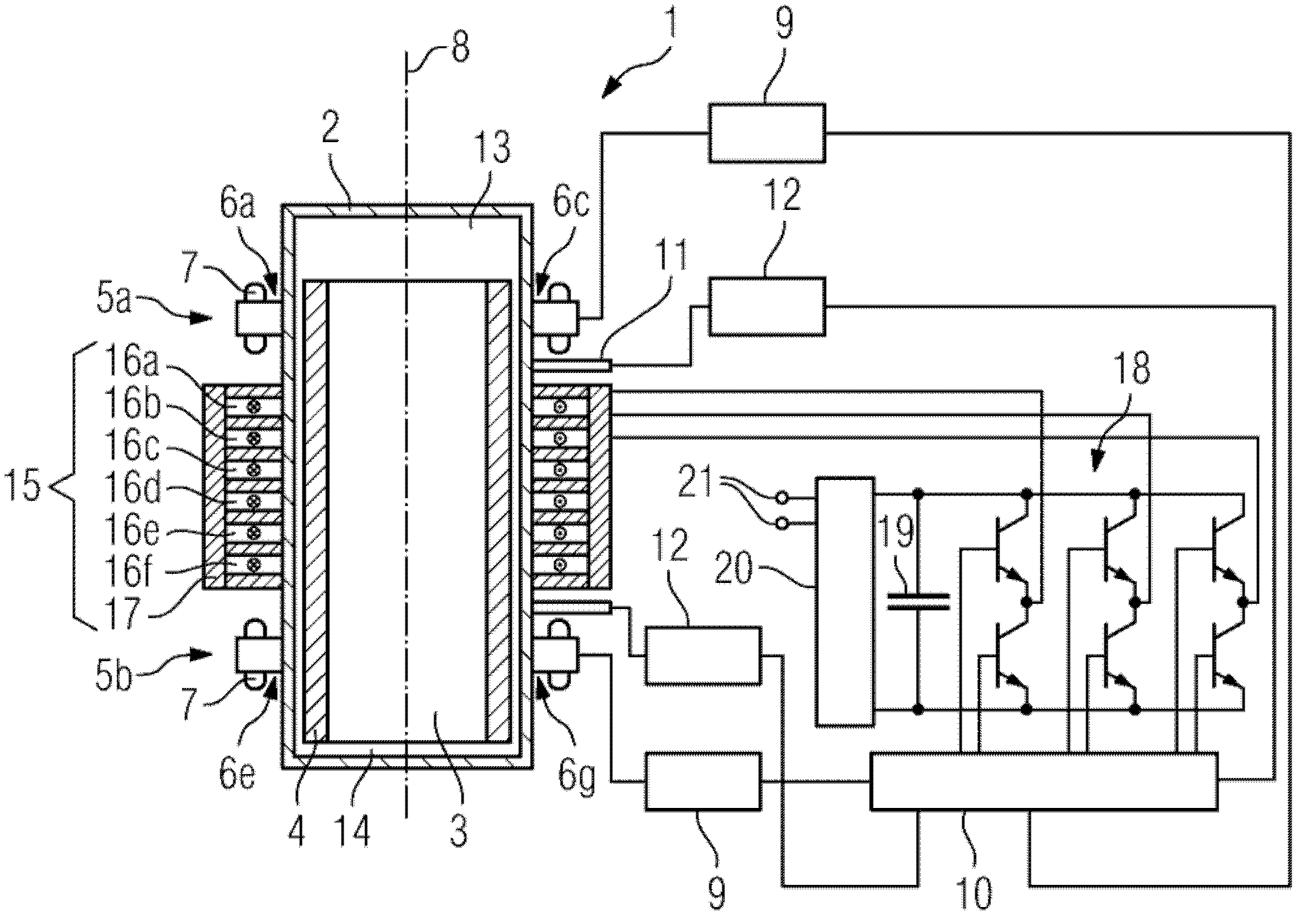

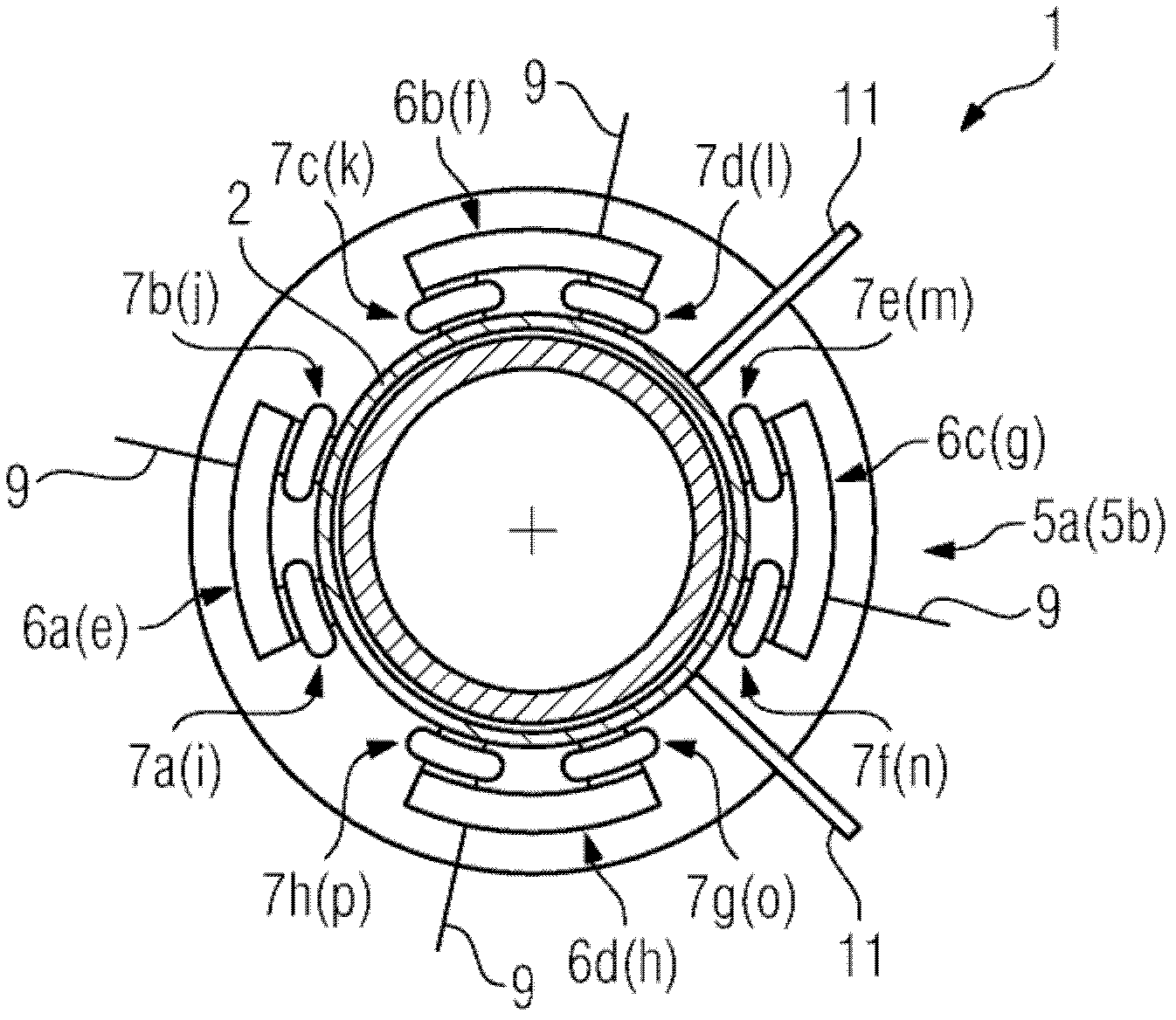

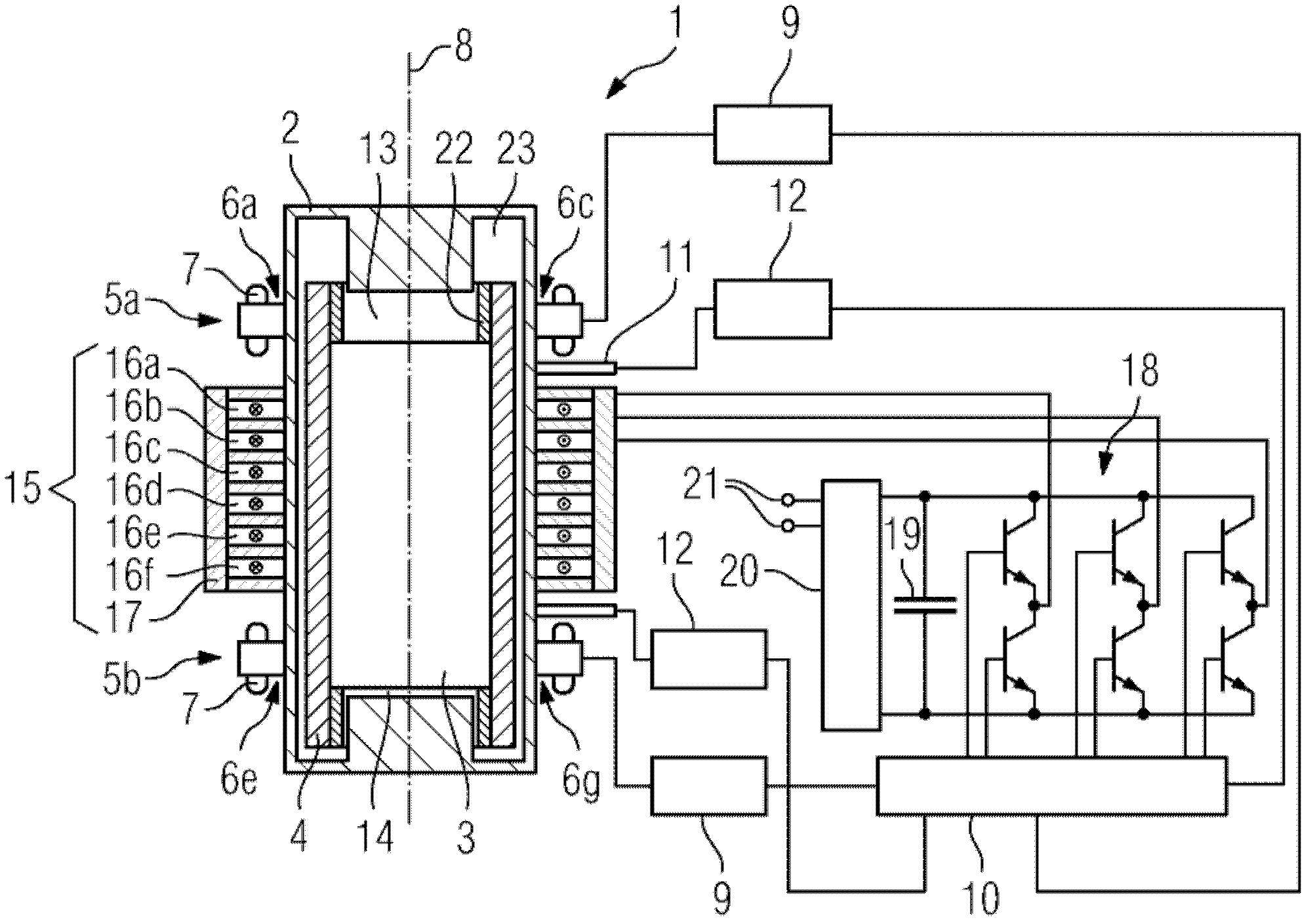

[0033] figure 1 A section of a piston machine 1 according to the invention is shown. The piston machine 1 has a cylindrical housing 2 in which a cylindrical piston 3 is movably mounted. A yoke 4 is provided on the outer peripheral surface of the cylindrical piston 3 . On the outside of the housing 2, at two positions 5a and 5b of its cylindrical outer circumference, at four support points 6a to 6d or 6e to 6g along the outer circumference, two magnets for magnetically supporting the piston 3 are respectively provided. Roads 7a to 7p. According to another embodiment not shown in the figure, there are three supporting points 6a to 6c, which each have a magnetic circuit 7a to 7f, which may be sufficient for a stable mounting of the piston. Combining the above numbers or depending on the use and force, the number of magnetic circuits can be changed according to the desired application. For simplicity, in figure 1 In the sectional view of , each position 5a and 5b only shows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com