Polar coordinate circular sawblade linear cutting method and linear cutting apparatus based on same

A wire cutting and circular saw blade technology, applied in the field of wire cutting equipment, can solve the problems of low work efficiency, enlarging the bed of the machine tool, and long time consumption, and achieve the effects of improving efficiency, improving radial runout accuracy, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

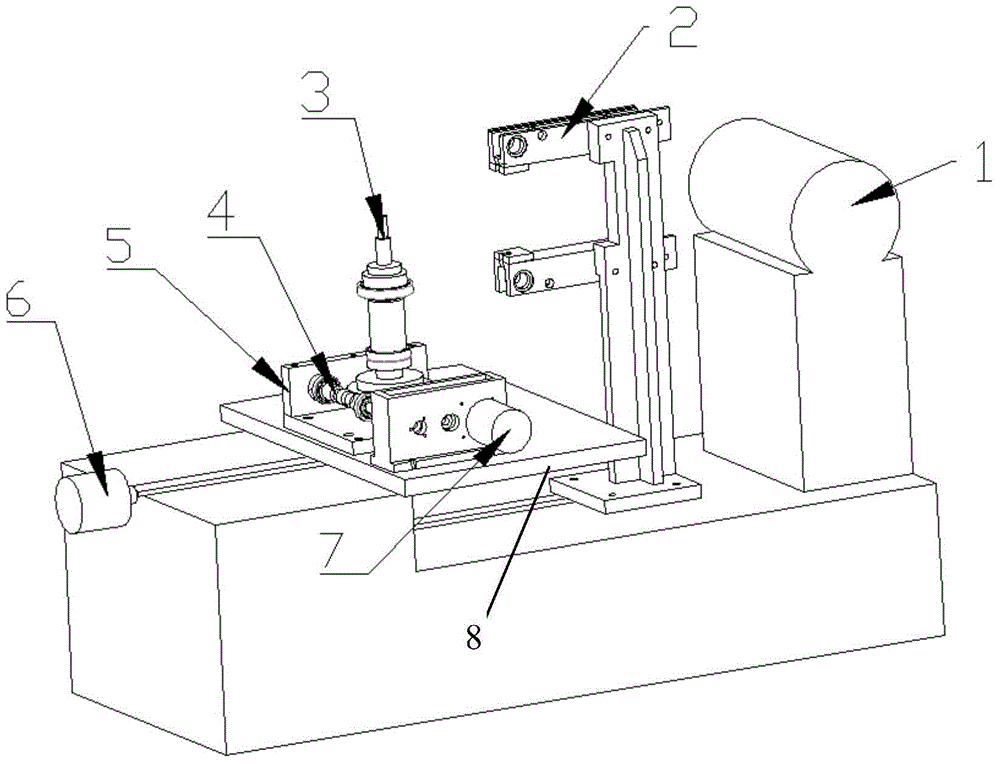

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

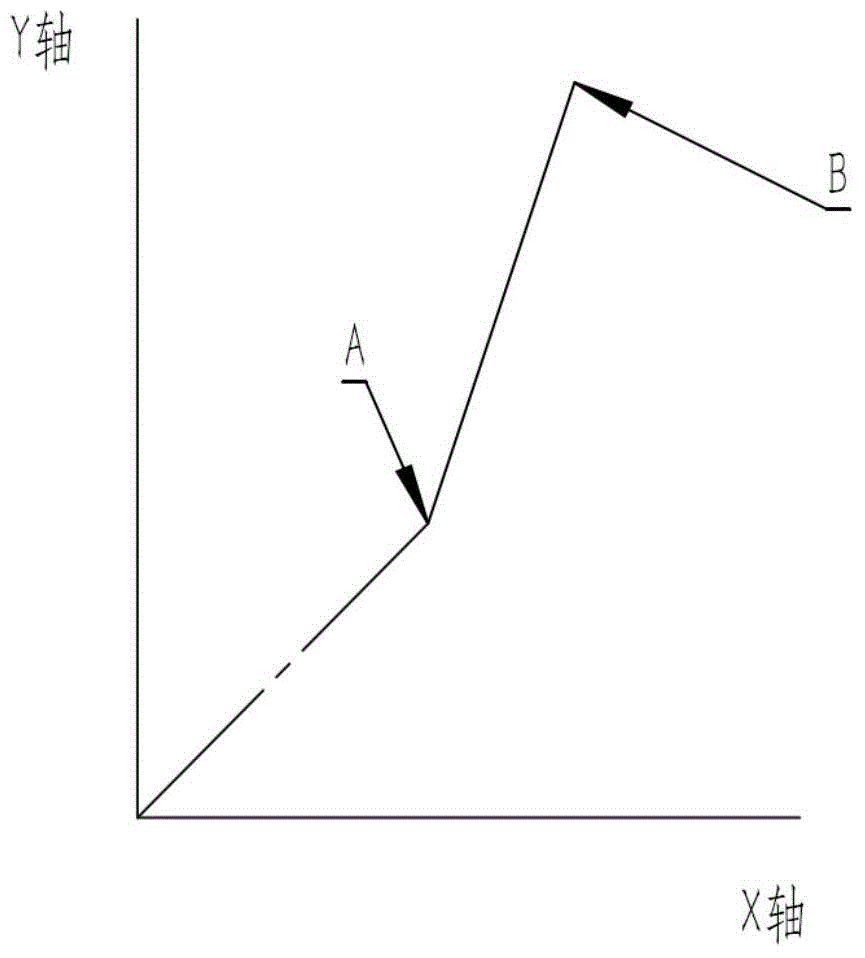

[0038] figure 1 are two points in the linear coordinate system, where the coordinates of point A are (20, 20), and the coordinates of point B are (30, 30). Assuming that the pulse is the same as the coordinate unit, the 3B code from A to B is:

[0039] B10 B30 B30 GY L1

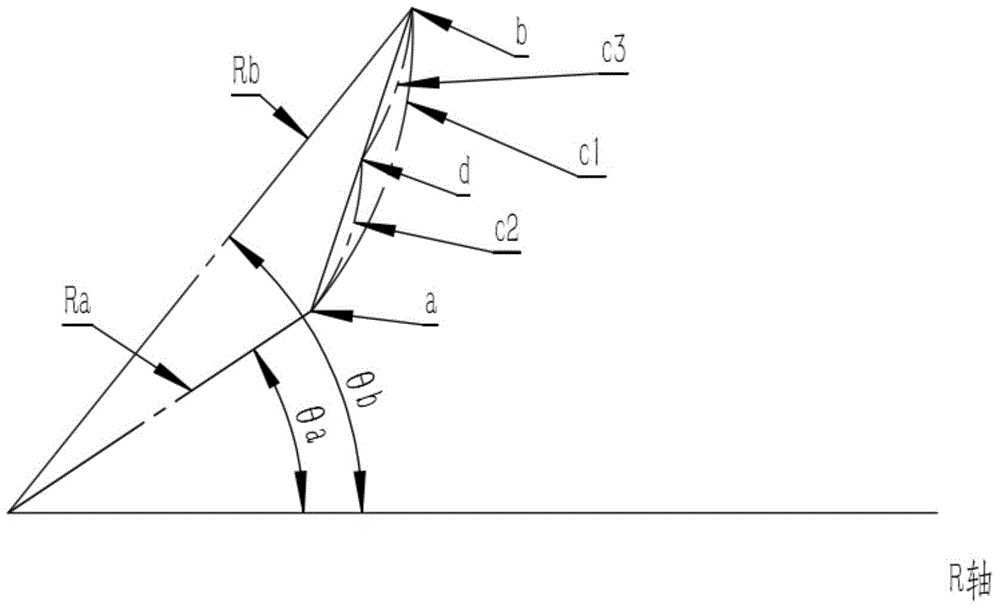

[0040] figure 2 are two points in the polar coordinate system, where the coordinates of A’ are (Ra, θa), and the coordinates of point B’ are (Rb, θb), according to the coordinate transformation formula:

[0041] R*R=X*X+Y*Y

[0042] sinθ=X / R

[0043] Assuming the number of pulses per revolution is 1000:

[0044] Then the coordinates of point A' are (28, 125), and the coordinates of point B' are (58, 164)

[0045] Then the 3B code from A' to B' is: B 30 B 39 B 39 GY L1

[0046] There is a one-to-one corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com