Device for calibrating temperature field of verification furnace automatically using standard thermocouples

An automatic calibration, thermocouple technology, applied in the direction of thermometers and thermometers using electrical devices, electrical/magnetic components directly sensitive to heat, etc., can solve the problems of slow test speed and cumbersome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

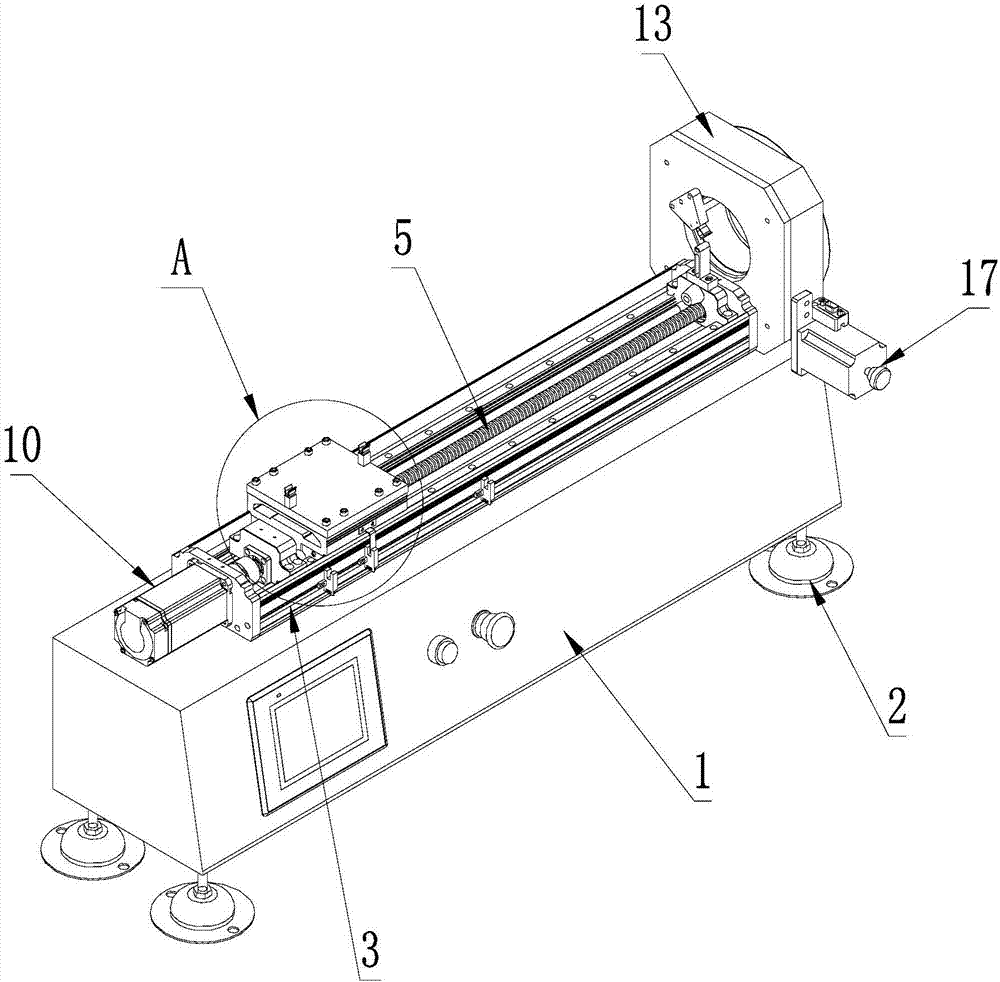

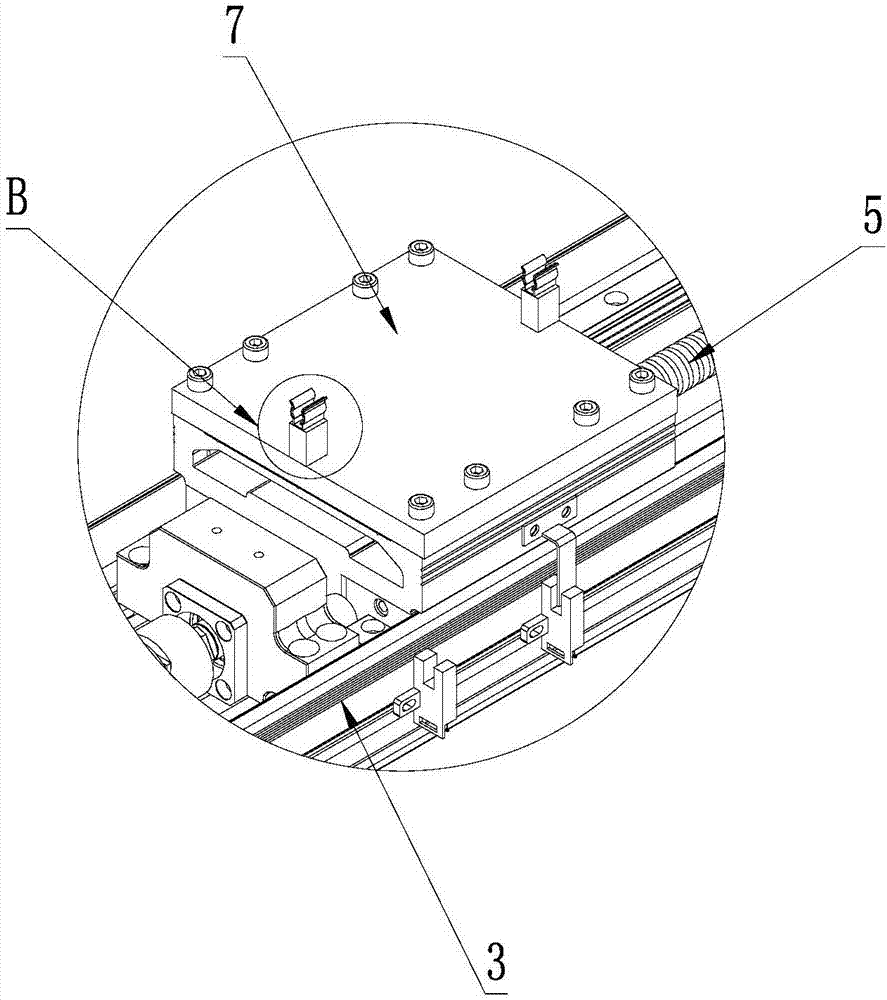

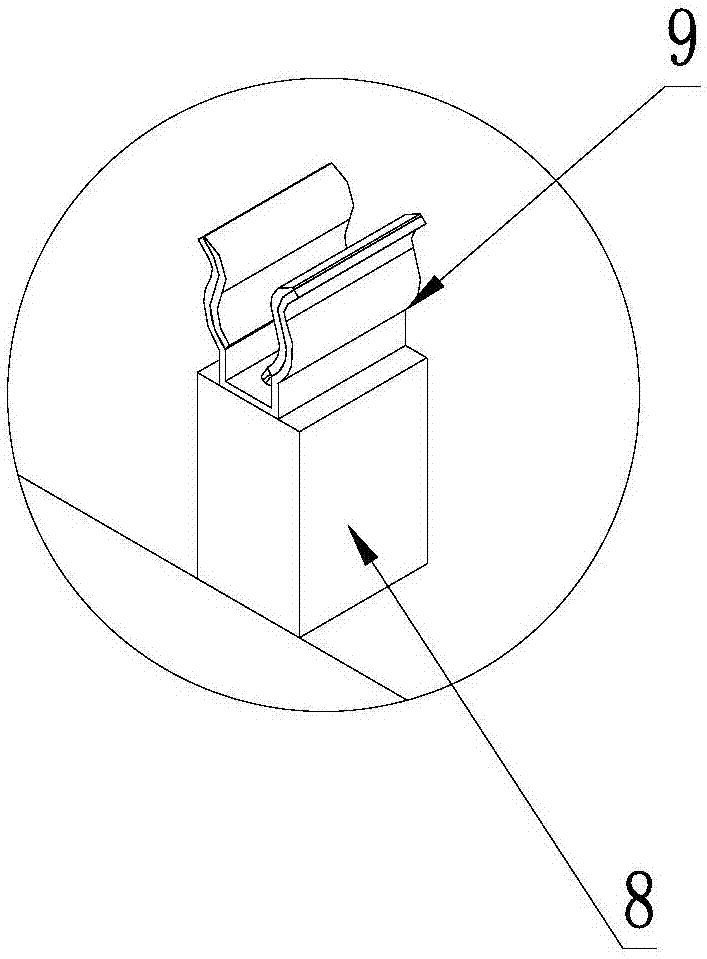

[0034] Such as Figure 1 to Figure 8 As shown in the figure, a device for automatically calibrating the temperature field of a verification furnace by using a standard thermocouple includes a base 1. The base 1 has a rectangular parallelepiped structure as a whole and is hollow in design. A controller composed of electronic control components is installed inside. There are holes on the body to install the touch screen and the master switch, wherein the master switch includes a power switch and an emergency stop switch. Four leveling feet 2 and leveling blisters are installed on the bottom plate of the base 1 , and the nuts of the feet 2 can be adjusted to adjust the level of the base 1 .

[0035] The top of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com