Method and apparatus for continuous processing of a flexible glass ribbon

A technology for processing equipment and glass ribbons, applied in glass manufacturing equipment, glass forming, glass forming, etc., can solve problems such as process instability, sheet vibration, adverse impact on downstream steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

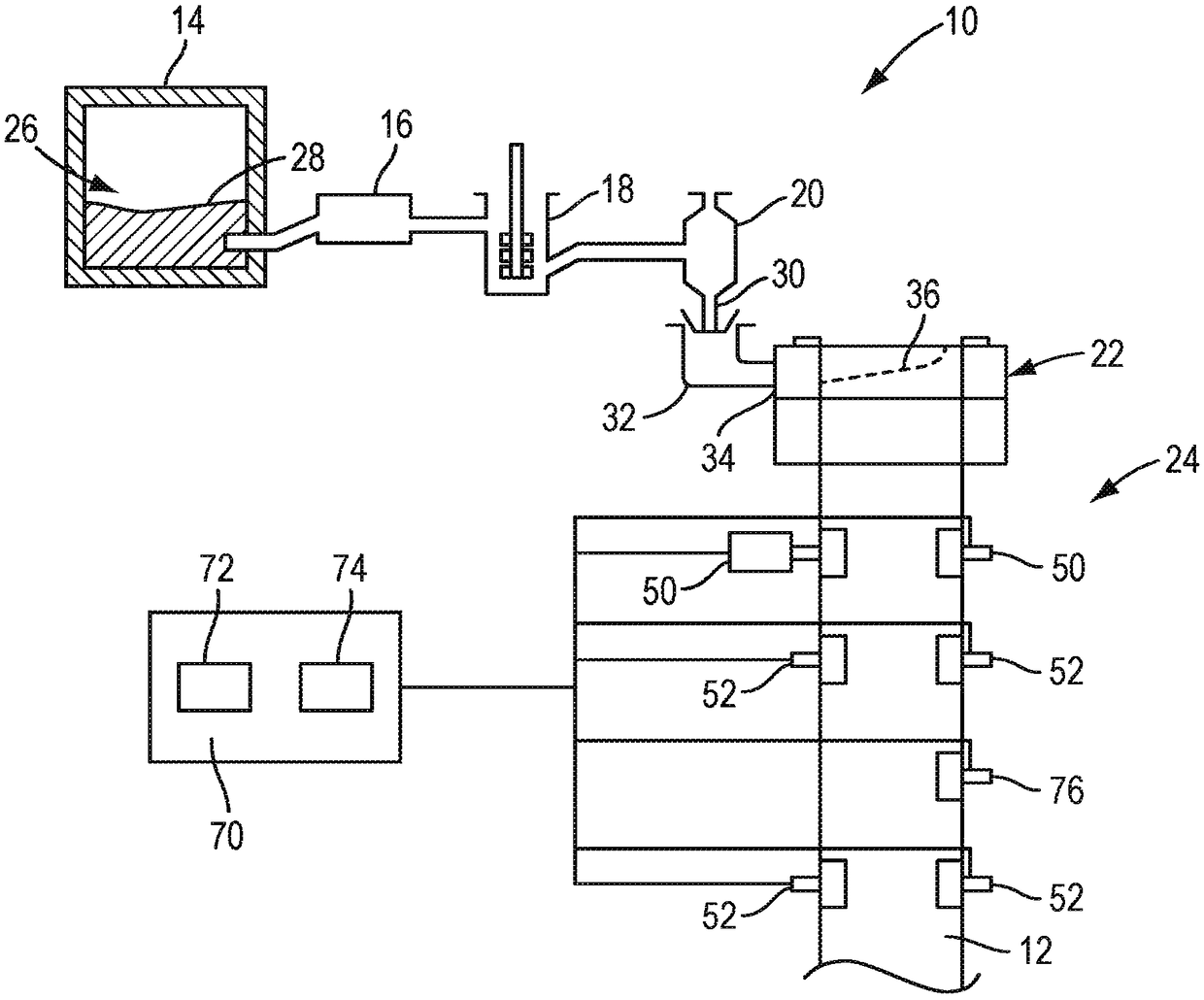

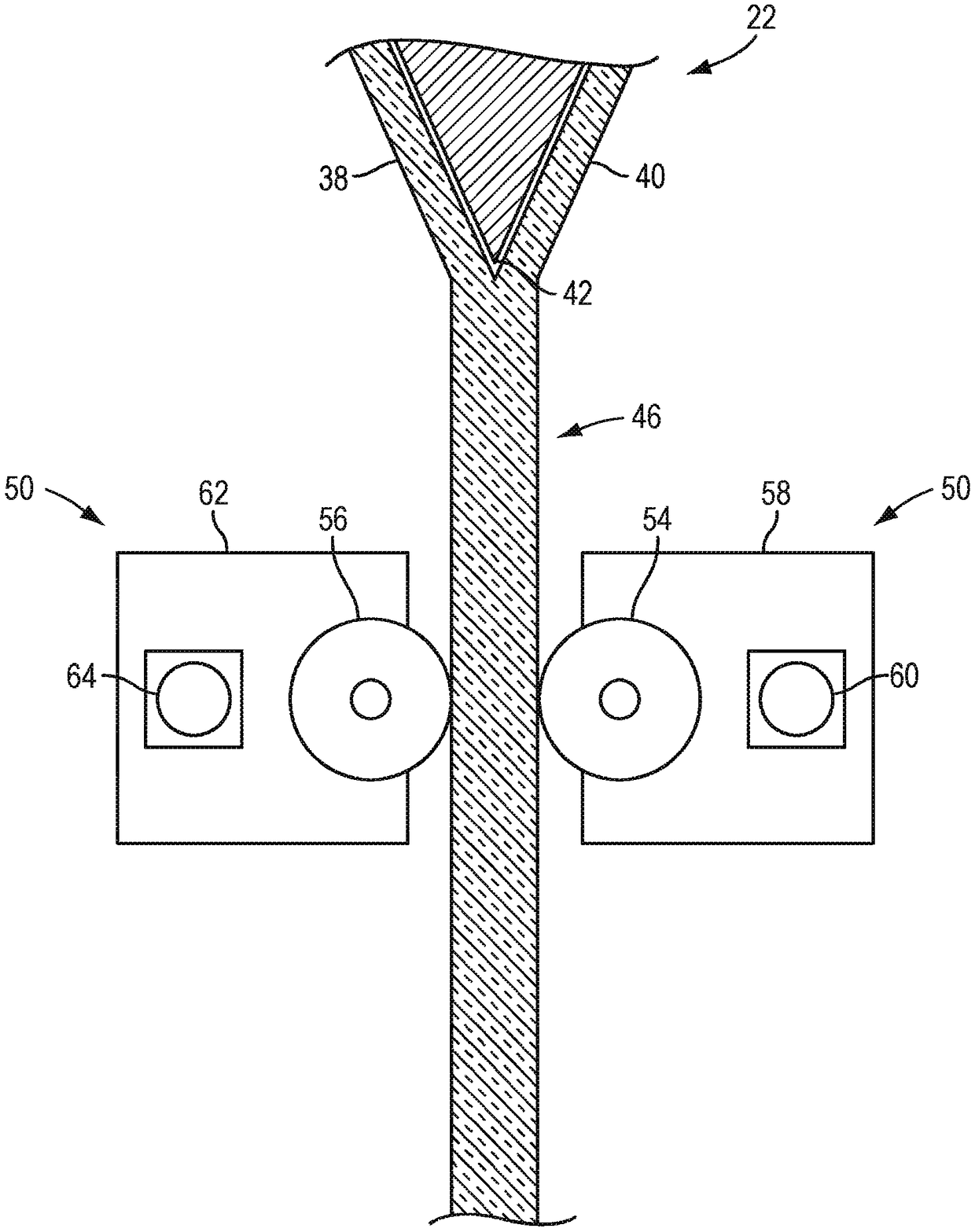

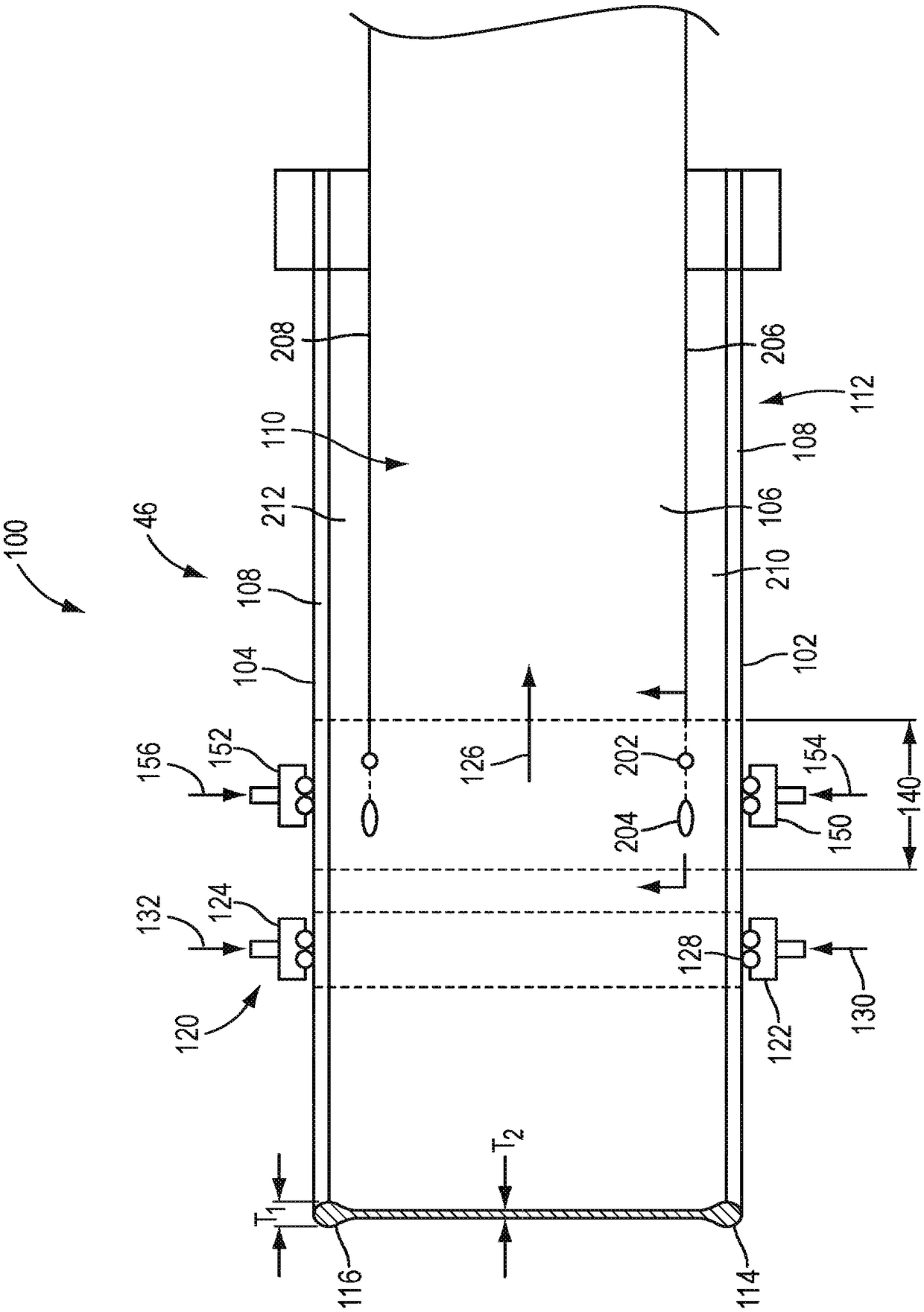

[0025] Embodiments described herein generally involve changing the MD and / or CD curvature (e.g., flipping from convex to concave curvature) of a continuous flexible glass ribbon at various locations throughout the process from root to winder or winder. Curvature) minimization, and the apparatus and method for the continuous manufacturing of flexible glass ribbon. A number of processing zones and buffer zones can be provided in the process wherein the shape of the continuous flexible glass ribbon can be controlled by positioning the zones relative to each other to minimize MD and / or CD curvature variations of the flexible glass ribbon. In some embodiments, the method can include maintaining the flexible glass ribbon with a concave or substantially linear MD and / or CD curvature through at least two or more adjacent regions in the process.

[0026] While glass is generally known to be a brittle material, inflexible, and prone to scratches, chips, and breaks, glass with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com