Wafer feeding device and wafer film pasting device

A film sticking device and wafer technology, applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve time-consuming and labor-intensive problems, achieve high efficiency, high degree of automation, and realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objects, technical solutions, and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the embodiments of the present invention are embodiments of the invention, not all of the embodiments. .

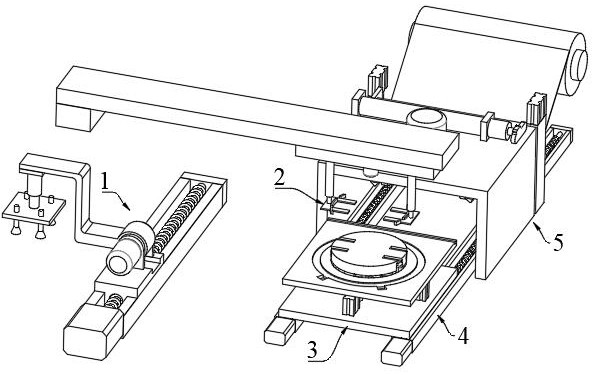

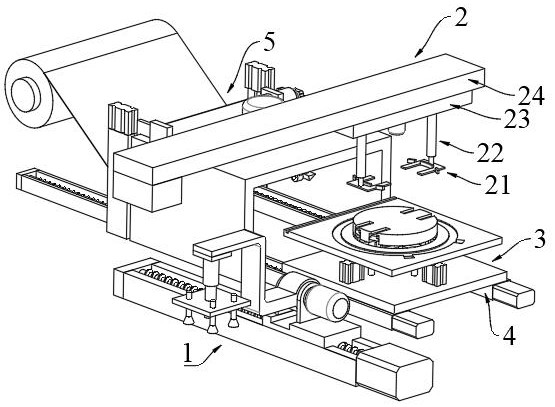

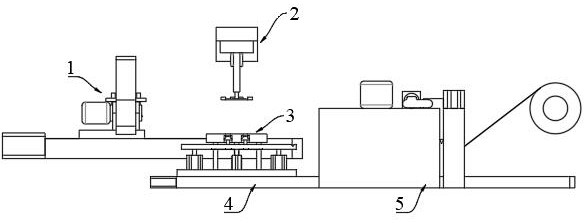

[0038] An aspect of an embodiment of the present application provides a wafer supply means, such as Figure 1 ~ 3 Shown, comprising: gripping means 1, the adapter means 2, support means 3.

[0039] Wherein a means for gripping a wafer stack from the stack to fetch the wafer, particularly the role of a protective film on one side of the wafer, because the other side is not placed directly receives the gripping action mechanism 1, which can avoid physical damage to the other surface of the wafer crawl; 1 further gripping mechanism for inverting the crawl, and conveyed linearly. Means for receiving the adapter 2 from the wafer after inversion grippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com